How Toyota Factory Works with Zortrax 3D Printers

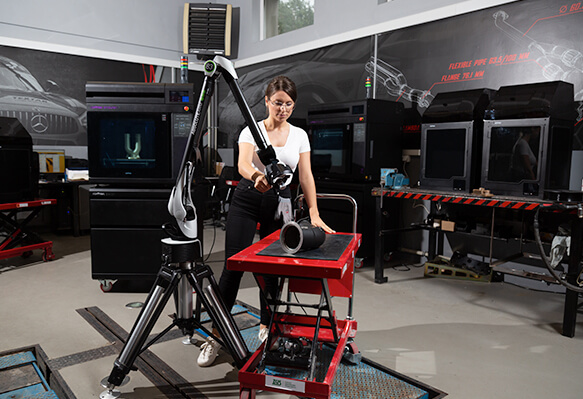

Toyota manufacturing plants in Poland specialize in assembling hybrid and conventional drives. Here's how they use Zortrax 3D printers.

Read More3D printers are groundbreaking, versatile tools bringing unmatched flexibility to manufacturing operations in both small workshops and large production plants.

Zortrax 3D printers are compatible with a range of high-quality printing materials from world-leading manufactures like Forward AM, Henkel/Loctite, Victrex, Nanovia, 3DXTech or Kimya.

These materials can be used for basic prototyping, manufacturing of durable end-use parts, or for making high-performance components meeting strict automotive standards.

The 3D printing system in a large automotive plant must ensure high efficiency in the production of parts and devices that improve the work of production lines. An example setup for a large factory therefore includes two Zortrax M300 Plus 3D, one Zortrax M300 Dual 3D, one Zortrax Inkspire 2 and one Zortrax Endureal 3D printers complemented by Zortrax Apoller, Zortrax Cleaning Station and Zortrax Curing Station post-processing devices.

Such setup is capable of working with full range of printing materials compatible with Zortrax 3D printers, including metals and enables doing most-of the post-processing work on the spot.

Small workshops specializing in custom jobs, car tuning or detailing typically don't need large outputs and have limited budget for a 3D printing system. Example setup covering most of the needs of such businesses include Zortrax M300 Plus or Zortrax M300 Dual 3D printers.

In this setup standard filaments are used for prototyping parts that after initial test runs get 3D printed with target materials, including metal filaments. Whenever more advanced materials are required, a workshop can commission the 3D printing to a chosen 3D printing services provider.

Multiple desktop and large-format industrial 3D printers as well as post-processing devices working in a single additive manufacturing ecosystem cover the entire product development process from prototyping and testing to manufacturing and post-processing of final parts.

Extrusion-based 3D printers are a perfect solution for workshops seeking to use cost-efficient 3D printing capabilities, rapid prototyping and on-the-fly design adjustments. Zortrax offers desktop and industrial 3D printers working in single or dual-extrusion technology:

UV LCD is a photopolymer resin 3D printing technology that works with outstanding precision and speed. Zortrax offers a complete resin 3D printing ecosystem with 3D printer and post-processing devices:

Z-SUITE 3D printing software with printing profiles for all supported materials and free over-the-air updates.

Covers stationary service and DIY repairs with online assistance from a technician.

Time-saving system for efficient managing of your 3D printers.

Fully equipped Starter Kit with necessary consumables.

Schedule an individual teleconference session with Zortrax representative to learn how Zortrax 3D printers may improve your business.

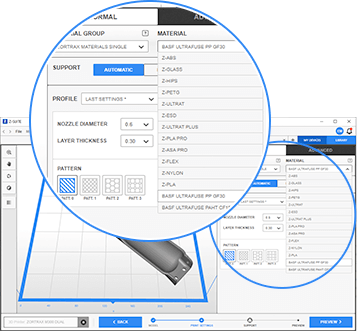

Contact usZ-SUITE is a powerful 3D printing software developed from the ground-up by Zortrax. 3D printable designs can easily be exported to Z-SUITE from CAD software, like AutoCAD, Autodesk Fusion 360, or SolidWorks. Z-SUITE comes free with every Zortrax 3D printer. It is compatible with 3D printing materials offered by both Zortrax and external suppliers.

Learn more

Z-SUITE comes equipped with an extensive base of thoroughly tested printing profiles for each supported material coming either from Zortrax or one of its trusted suppliers. Using those printing profiles guarantees best possible results when printing with supported materials.

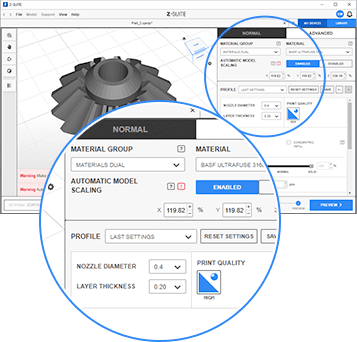

Metal 3D printing requires rescaling of the printed models to account for shrinkage happening at the post-processing stage when the printed model is turned into steel. Z-SUITE does the scaling automatically to ensure the dimensions of steel parts are exactly as specified in the part's design.

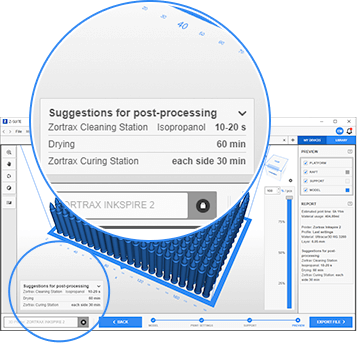

3D printing with photopolymer resins is a process that requires cleaning and curing 3D printed parts. Z-SUITE has built-in post-processing suggestions explaining what exactly has to be done to achieve target mechanical and thermal properties in the resin 3D printed part.

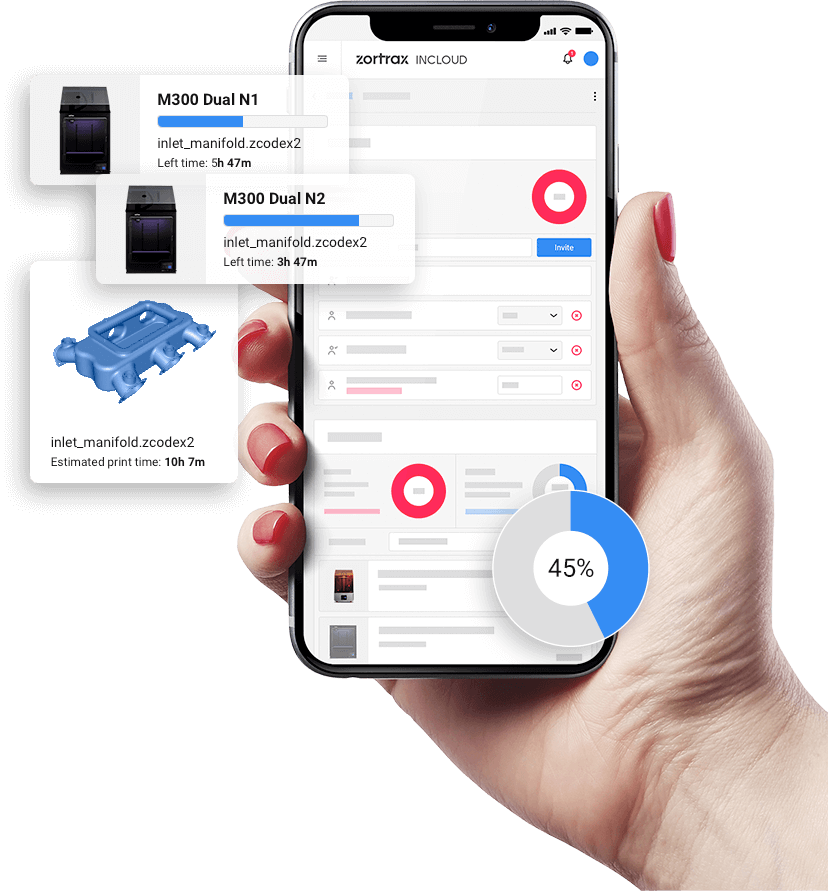

Zortrax inCloud is a cloud-based platform designed for remote management of available 3D printing staff and equipment.

Printing of a single model can be simultaneously started on all Zortrax 3D printers connected to the inCloud account.

With inCloud, it is possible to remotely manage large clusters of Zortrax 3D printers. Each device in a cluster can be controlled individually even if each works in a different place.

Zortrax inCloud operates using servers located in the Zortrax HQ in Poland which means users data is processed and hosted in a safe location in the European Union.

inCloud platform has been developed entirely by Zortrax which means it can be tailored to individual customers need if necessary.

Learn more about how implementing Zortrax 3D printing solutions benefits both small automotive workshops and

world-leading brands like Toyota.

user-stories How Toyota Factory Works with Zortrax 3D Printers

user-stories Automotive Plant Uses Zortrax Endureal to Upgrade Its Machines

user-stories Reducing Production Costs with 3D Printed End-Use Items

user-stories

3D Printing in Automotive:

A Low-Cost Method to Upgrade Your Car

user-stories Why Modern Car Designers Use 3D Printers

user-stories Resin 3D Printing in Manufacturing of Automotive Parts

Fill in the short form below and we will get in touch to help you build the right 3D printing system for you needs.

Our representative will contact you shortly.