Why bridge manufacturing is good for business

Bridge manufacturing enables smooth transition from prototyping to full-scale production.

Bridge manufacturing solves three major problems businesses face when launching a new product

-

Products, at the end of the prototyping stage, have limited or lacking market validation

-

Significant tooling expenses are necessary to set up production lines for those unproven products

-

Once the production lines are set up, the design can't be changed without time and resource-intensive retooling

Flexible manufacturing

A cluster of 3D printers can perform short-run production with no tooling costs.

Market validation

An initial series of a product can be used for market validation.

Generation of revenue

Fully-functional 3D printed products can be sold to customers to generate income.

No retooling

Once one product reaches the mass manufacturing stage, 3D printers can start producing the next one.

Workflow in bridge manufacturing

A properly implemented bridge manufacturing process creates a feedback loop between the product development department, the manufacturing, and the target audience. Here's how it works.

Step 1: Initial prototyping

Product development department comes with a feasible product's design.

Step 4: Feedback processing

Feedback from the audience is used to adjust the design in the product's development department.

Step 2: 3D printing

A short series of a new product is made on 3D printers.

Step 3: Target audience

Firs couple hundred products are provided to the target audience.

Step 1: Initial prototyping

Product development department comes with a feasible product's design.

Step 2: 3D printing

A short series of a new product is made on 3D printers.

Step 3: Target audience

Firs couple hundred products are provided to the target audience.

Step 4: Feedback processing

Feedback from the audience is used to adjust the design in the product's development department.

Technologies for bridge manufacturing

The choice of the right 3D printing technology for bridge manufacturing depends on the size and complexity of products under development.

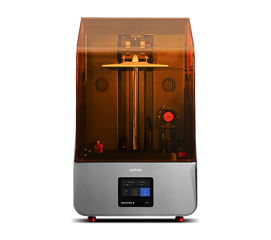

Precise engineering and electronics

Resin 3D printing technologies like the Zortrax UV LCD are best for small yet complex products made in high quantities.

See more

Medium size products with simple geometry

LPD technology is the most cost-efficient for making medium size simple products like lamps or remote controllers.

See more

Medium size products with complex geometry

LPD Plus technology is best for intricately designed, medium size parts like movable mechanism or organic shapes.

See more

High-quality end-use products

SVS automated post-processing devices can be used with LPD, LPD Plus and all other FDM printers to achieve a quality finish for the final version of the product intended for paying customers.

See more