Step 1 Impression taking

Areas of interes in the patient's oral cavity are scanned with intraoral scanners or 3D Roentgen equipment. Resulting digital 3D models go straight to dental CAD/CAM software.

Digital dentistry powered by the 3D printing technology is fast, convenient for the patient, and precise.

A 3D printer working as a part of a larger digital dentistry system allows to see more patients per day. It also cuts costs, reduces human error, and guarantees better quality service for the patient.

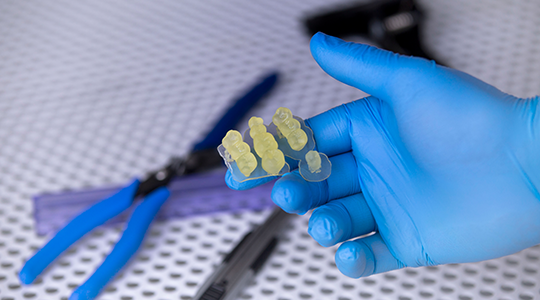

Appliances like dental crows, bridges, and surgical guides can be 3D printed directly with biocompatible resins. Castable resins can be used to make investment patterns for casting dental alloys.

From impression taking to end-use dentures, crowns, or orthodontic appliances, digital dentistry is changing the way dental labs and practices work. Each step of traditional dental modeling has got improved, digitized, and automated. Here's how it works.

Areas of interes in the patient's oral cavity are scanned with intraoral scanners or 3D Roentgen equipment. Resulting digital 3D models go straight to dental CAD/CAM software.

From splints and crowns to entire bridges or dentures, modern dental CAD/CAM software can make personalized designs perfectly fitted to the patient's anatomy.

After the design stage, a CAD/CAM software can send the model to digital manufacturing devices like dental resin 3D printers working with microscopic precision.

Zortrax Inkspire is a resin UV LCD 3D printer using a high resolution LCD screen with UV light source placed beneath it to build precise models by solidifying photopolymer resins layer by layer. It is a Plug & Play device with a simple, intuitive interface which makes it easy to operate even without prior 3D printing experience.

Zortrax Inkspire has all it takes to work as a dental resin 3D printer.

Z-SUITE is a dedicated slicing and 3D printing farm management software that comes free with every Zortrax 3D printer. It is compatible with the most popular dental CAD/CAM software solutions like inLab CAD SW 18 or ZFx Dental CAD Design Software. Zortrax Inskpire can also work with third-party slicers.

Recommended for precise dental study models. It's a precise dental resin with a gypsum-like texture. Offers very high level of detail sufficient for accurate modeling of teeth and gums. This resin is not biocompatible and is not meant for intraoral use.

Recommended for clear surgical guides. Class I biocompatibility makes it safe for transient contact with a human body. Translucency guarantees optimal visibility during the procedure. Models must be sterilized prior to intraoral use.

Recommended for temporary crowns and bridges. Class IIa biocompatibility makes it safe for up to 30 days of contact with human tissue. Highly resistant to abrasion. Available in the A2 shade. Models must be sterilized prior to intraoral use.