How 3D printers improve health care

A radiograph of a hip with 3D printed implant.

Clinicians face three major problems 3D printers can solve

-

Customized pre-surgical planning models take a lot of time to make

-

Patient-specific anatomical features can be identified only on digital models

-

Implants are sometimes shaped during the surgery which makes the procedure longer

Pre-surgical planning

3D printers can quickly fabricate precise real-size pre-surgical planning models based on CT scans.

Improved communications

Physical, anatomical models help patients better understand their conditions and procedures they are about to undergo.

Simple implementation

Modern 3D printers are easy to operate even by personnel with no prior training or experience with this kind of equipment.

Shorter surgeries

Implants used in facial reconstruction surgeries can be shaped in advance on patient-specific anatomical models, rather than during the surgery.

Workflow in 3D printing at hospitals

Clinicians can implement 3D printers in their practice following four simple steps. Here's how it works.

Step 1: Modeling

Digital anatomical models are created based on CT scans.

Step 2: 3D printing

Physical, real-size anatomical models are 3D printed.

Step 4: Pre-surgical planning

Physical patient-specific models are used for planning the surgery and training.

Step 3: Communications

3D printed models are used to explain the procedure to the patient.

Step 1: Modeling

Digital anatomical models are created based on CT scans.

Step 2: 3D printing

Physical, real-size anatomical models are 3D printed.

Step 3: Communications

3D printed models are used to explain the procedure to the patient.

Step 4: Pre-surgical planning

Physical patient-specific models are used for planning the surgery and training.

Customized medical devices

3D printers make it possible to fabricate customized medical devices designed to solve problems specific for particular surgeon's practice. A fully functional medical winch made to close varicose veins has been 3D printed at the MEDIQ clinic based in Poland.

3D printer in facial reconstruction surgery

Doctors at the Oral and Maxillofacial Surgery Ward of Clinical University Hospital in Olsztyn, Poland, work with full-scale models of patients’s skulls 3D printed based on CT scans. Those models help in shaping personalized implants prior to surgery. 55% of the patients admitted to the ward suffer from orbital traumas and over 80% of those cases require orbital floor reconstruction. 3D printers make their treatment more effective and safer.

Pre-surgical planning models

Pre-surgical planning models are 3D printed based on CT scans for surgeons to think through and practice the procedure they are about to perform on the patient. The human heart model has been used to plan and train a pulmonary valve insertion.

Technologies for bridge manufacturing

The choice of the right 3D printing technology for bridge manufacturing depends on the size and complexity of products under development.

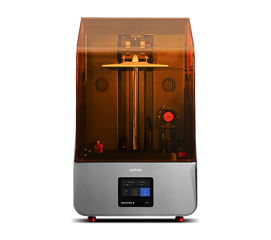

Small size models with complex geometry

Resin 3D printing technologies like the Zortrax UV LCD are best for small yet very precise models and biocompatible devices ready for sterilization.

See more

Medium size models with simple geometry

LPD technology is the most cost-efficient technology for making simple medium size models like bones.

See more

Medium size models with complex geometry

LPD Plus technology is best for intricately designed, medium size models with complex internal architectures like anatomical models of the human heart.

See more

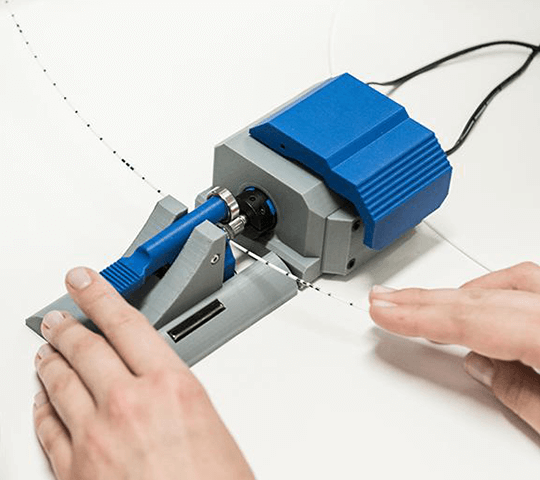

Medium size models with smooth surfaces

SVS automated post-processing devices can be used with LPD or LPD Plus printers to make models with superior aesthetics for communications.

See moreOur Users stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.