How 3D printers improve on-demand manufacturing

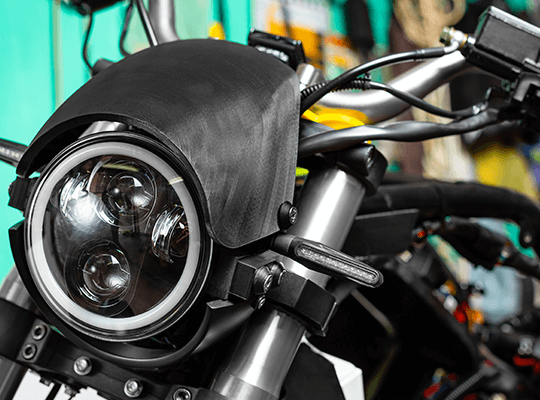

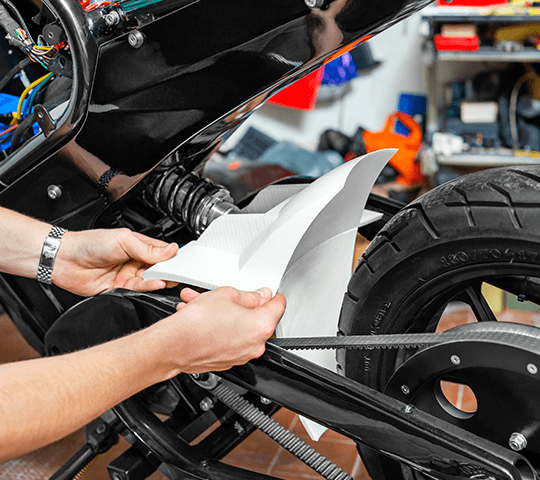

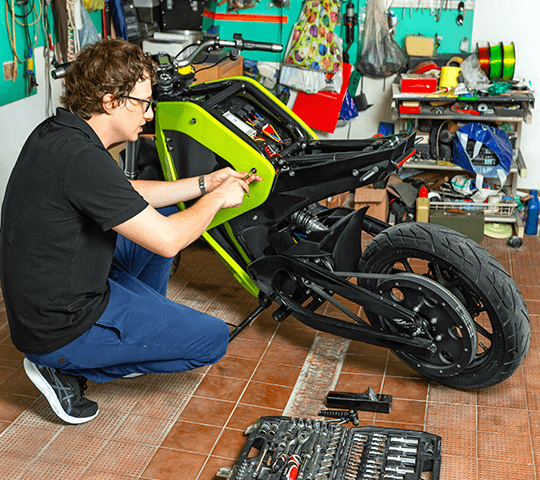

Prototype motorcycle components 3D printed on spec for a customer.

Businesses offering on-demand manufacturing services face three major challenges

-

Product design and order quantity can vary greatly

-

Traditional manufacturing technologies have high MOQ threshold of profitability

-

Efficiency of traditional manufacturing tools is heavily affected by products' design

No MOQ

3D printers fabricate models at a steady price regardless of the order quantity, so there is no need to force a high MOQ upon customers.

Simple toolset

Almost all shapes can be fabricated on 3D printers, so there is no need for having specialized tools for different designs.

Short lead times

Ordered products get to customers faster because 3D printers can start working on the assignment immediately with no time wasted on tooling.

Less human labor

Fabrication on 3D printers is for the most part done automatically with no need for human supervision, so it requires minimal workforce.

Workflow in 3D printing services

Businesses offering on-demand manufacturing can implement implement 3D printers following four simple steps. Here's how it works.

Step 1: Design optimization

Customer's product design is optimized for 3D printing.

Step 2: Choice of material

The right material is chosen to meet customer's requirements.

Step 4: Post-processing

Appropriate post-processing techniques are applied if necessary.

Step 3: 3D printing

Fabrication is assigned to available 3D printers.

Step 1: Design optimization

Customer's product design is optimized for 3D printing.

Step 2: Choice of material

The right material is chosen to meet customer's requirements.

Step 3: 3D printing

Fabrication is assigned to available 3D printers.

Step 4: Post-processing

Appropriate post-processing techniques are applied if necessary.

Automotive prototyping

Falectra has built a fully functional prototype electric motorbike with 3D printed components.

Technologies for 3D printing services

The choice of the right 3D printing technology for an on-demand manufacturing business depends on the complexity of ordered products and the MOQ.

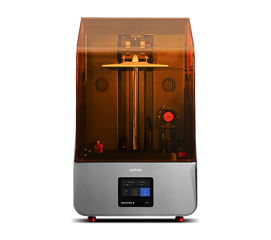

Small size products with complex geometry

Resin 3D printing technologies like the Zortrax UV LCD are best for small yet intricately designed products ordered in large quantities.

See more

Medium size products with simple geometry

LPD technology is the most cost-efficient for making simple medium size products in large quantities.

See more

Medium size products with complex geometry

LPD Plus technology is best for intricately designed, medium size details with complex internal architectures ordered in small to medium quantities.

See more

Medium size products with smooth surfaces

SVS automated post-processing devices can be used with LPD or LPD Plus printers to achieve superior aesthetics in large quantities of products.

See more