How 3D printing improves architecture modeling:

3D printed apartment cross-section.

Businesses face three major challenges in building architectural mock-ups and scale models

-

Balance accuracy and production time

-

Ensure repeatability of results

-

Achieve superior aesthetics

Streamlined process

A 3D printer can fabricate a scale model of a proposed structure based on a CAD design which is usually available at this stage of creative process in architecture.

Results repeatability

Unlike human model makers, a 3D printer relies on technology rather than craftsmanship which leads to almost perfectly repeatable results.

Superior precision

Model making in architecture requires utmost precision down to tenths of a millimeter. Desktop 3D printers can easily achieve that level of dimensional accuracy.

Ease of use

A 3D plug & play printer can be operated by anyone at the office. There is no need for extensive training or engineering expertise.

Workflow in architecture modeling

Architecture modeling with 3D printers can be done in four simple steps. Here's how it works.

Step 1: CAD design

A 3D printer can work with the 3D models previously used for architecture rendering.

Step 2: 3D printing

A model can be 3D printed within 1-3 days, depending on its size.

Step 4: Assembly

Larger mock-ups or layout models are assembled from 3D printed parts.

Step 3: Post-processing

3D printed models are post-processed if necessary.

Step 1: CAD design

A 3D printer can work with the 3D models previously used for architecture rendering.

Step 2: 3D printing

A model can be 3D printed within 1-3 days, depending on its size.

Step 3: Post-processing

3D printed models are post-processed if necessary.

Step 4: Assembly

Larger mock-ups or layout models are assembled from 3D printed parts.

3D printing architectural mock-ups

3D printers are used by top-tier architects to build scale mock-ups of their projects. Designers at Barozzi Veiga Architects based in Barcelona, Spain, 3D printed concept models of their award-winning philharmonic hall now located in Szczecin, Poland.

Technologies for architecture modeling

Read more about the impact 3D printing technology has on businesses that have implemented it already.

Small size parts with complex geometry

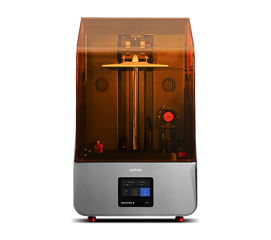

Resin 3D printing technologies like the Zortrax UV LCD are best for fabricating small yet intricately designed details.

See more

Medium size parts with simple geometry

LPD technology is the most cost-efficient for making simple medium size objects that can become parts of large layout models.

See more

Medium size models with complex geometry

LPD Plus technology is best for intricately designed, medium size models like movable structures or organic shapes.

See more

Aesthetically pleasing medium size models

SVS automated post-processing devices can be used with LPD or LPD Plus printers to achieve superior surface aesthetics.

See moreOur Users stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.