Introducing metal 3D printing

Working with BASF Forward AM we've introduced Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH: kits that enable 3D printing models made of two most commonly used types of steel: 316L surgical-grade stainless steel and 17-4 PH hardened steel.

Here's all you need to know about surgical-grade stainless steel included in the Zortrax Full Metal Package 316L.

Stainless steel contains over 10% of chromium which in contact with oxygen forms a thin surface layer protecting it from corrosion as well as making this alloy esthetically pleasing, easy to maintain and sterilize. The downside is the chromium makes 316L steel relatively soft. 316L stainless is used for:

- Corrosion-resistant automotive parts

- Parts exposed to chemicals and liquids

- Decorative parts like trims and grills

- Hydraulic systems' components

- Food containers

- Medical equipment

- Corrosion-resistant precision mechanisms

Parts made with Zortrax Full Metal Package 316L are isotropic and can be welded, polished or machined just like standard steel.

M300 Dual: Zortrax Full Metal Package 316L contains everything you need to make parts out of stainless steel on the Zortrax M300 Dual 3D printer. The package includes:

- 1000 g spool of BASF Ultrafuse® 316L metallic powder filament

- A 300 g spool BASF Ultrafuse® Support Layer

- Magigoo® Pro Metal 50ml glue

- M300 Dual hotend module with steel nozzle

- PTFE tube with Adapter

- Post processing voucher for a 500 g of metal parts

- Bubble wrap to secure your 3D printed parts for transit

BASF Ultrafuse® 316L metallic powder filament and BASF Ultrafuse® Support Layer are available for purchase separately.

Zortrax Full Metal Package 316L contains everything you need to make parts out of 316L surgical-grade stainless steel on the Zortrax Endureal 3D printer. The package includes:

- 1000 g spool of BASF Ultrafuse® 316L metallic powder filament

- A 300 g spool BASF Ultrafuse® Support Layer

- Magigoo® Pro Metal 50ml glue

- Endureal hotend module

- Post processing voucher for a 500 g of metal parts

- Bubble wrap to secure your 3D printed parts for transit

BASF Ultrafuse® 316L metallic powder filament and BASF Ultrafuse® Support Layer are available for purchase separately.

How to use Zortrax Full Metal Package 316L

Printing

Green Part

Printing

Green Part

Debinding

Brown Part

Debinding

Brown Part

Sintering

Metal Part

Sintering

Metal Part

The process is simple. You replace a standard hotend module with the one included in the package, load the included printing and support filament, cover the build platform with included Magigoo Pro Metal glue, print your parts using default settings in Z-SUITE, send the parts for post processing using the included voucher, get your post-processed metal parts delivered to your doorstep. To make best possible metal parts with the Zortrax Full Metal Package 316L you need to follow a few simple guidelines and design principles. They are all clearly explained in our metal 3D printing step by step manual.

BASF Ultrafuse® 316L is an industrial composite filament compatible with the LPD Plus Zortrax Endureal 3D printer. It has features that allow users to produce metal parts in a safe, easy, and cost-effective way in comparison with Metal Injection Molding, Selective Laser Sintering or metal machining. The filament contains 80% 316L stainless steel particles and 20% of polymer content.

BASF Ultrafuse® 316L can be used for 3D printing complex metal end-use parts, functional prototypes, medical equipment, automotive parts, chemical pipes or valves, elements of tools or fixtures. Printed parts have up to 561 MPa tensile strength, 251 MPa yield strength, up to 53% elongation at break, and have austenitic (non-magnetic) microstructure.

3D prints gain their unique properties through the proprietary catalytic debinding and sintering process, outsourced at Elnik Systems GmbH. During this process, 3D printed “green parts” turn into fully metal “brown parts.” As a result you receive non-magnetizable elements with high corrosion resistance. During the post-processing procedures, BASF Ultrafuse® 316L models shrink by about 20%. This effect should be taken into account when preparing models for 3D printing.

Available Colors

| Dedicated for | Container | Weight | Diameter | Extrusion |

|---|---|---|---|---|

| Zortrax M300 Dual | spool | 3000 g ± 5% or 1000 g ± 5% | 1.75 mm | Dual with BASF Ultrafuse® Support Layer |

| Zortrax Endureal |

| Key Properties | Metric | Imperial | Test Method |

|---|---|---|---|

| Tensile strength | 561 MPa | 81.37 ksi | ISO 6892-1 |

| Yield strength | 251 MPa | 36.4 ksi | ISO 6892-1 |

| Elongation at break | 53% | 53% | ISO 6892-1 |

| Vickers hardness (HV10) | 128 | 128 | ISO 6507-1 |

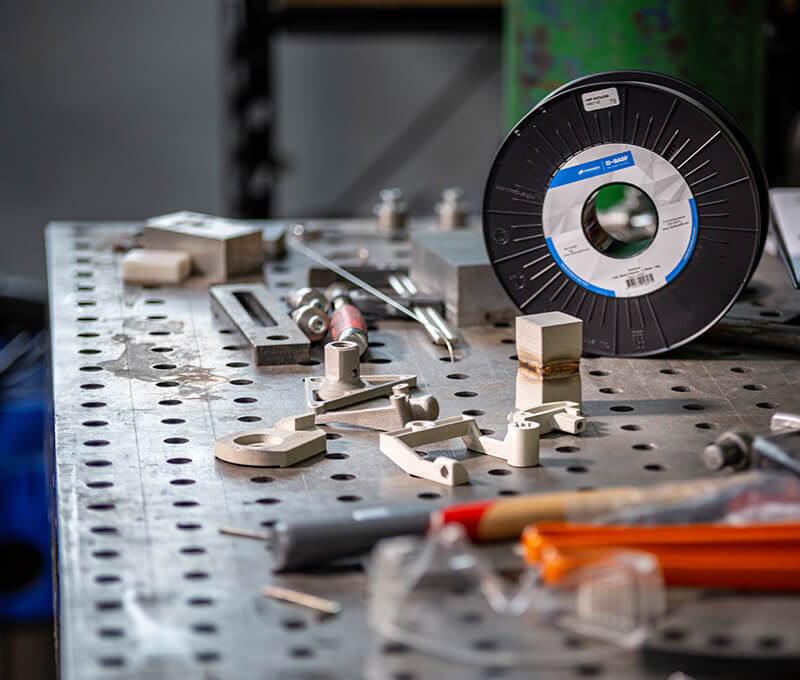

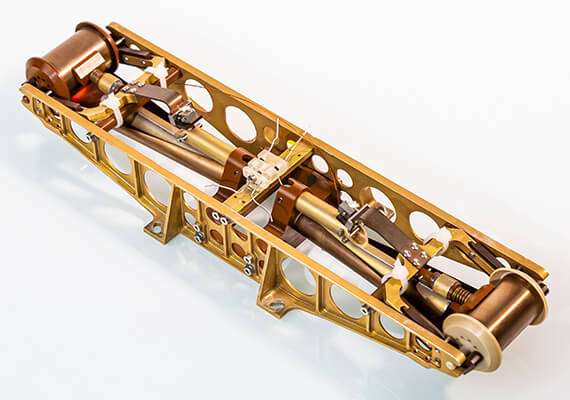

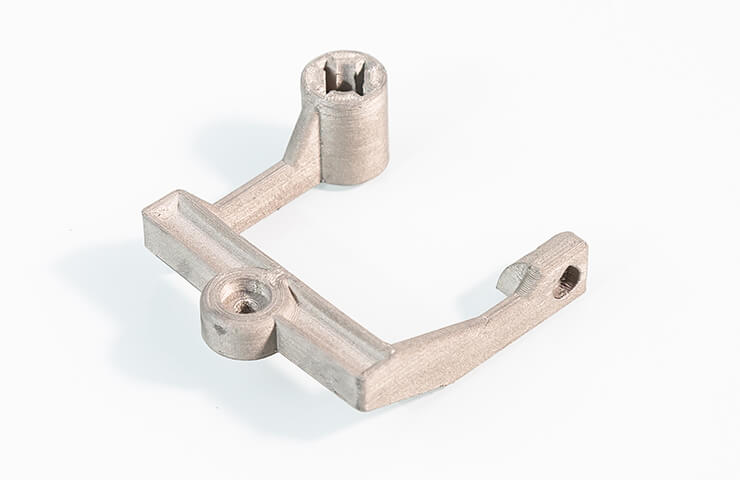

A model of a space-grade single dipol antenna unit made for the JUICE (Jupiter Icy Moons Explorer) mission by Astronika, a space industry manufacturer that seeks to implement metal 3D printing in their workflow.

Applications

- functional prototypes,

- metal end-use parts, such as electronics covers,

- medical equipment,

- automotive parts, such as engine brackets,

- components for chemical industry,

- parts intended for welding,

- tooling, jigs, fixtures.

Non-magentic

The material has austenitic, non-magnetic structure.

Stainless

A thin layer formed by chromium in contact with oxygen provides corrosion-resistance.

Medium hardness

Low percentage of carbon makes the 316L steel relatively soft.

BASF Ultrafuse® Support Layer

BASF Ultrafuse® Support Layer is a support filament dedicated for metallic powder filaments. Using it is crucial to achieve desired parts' geometry both during the 3D printing and post-processing stage.

Available Colors

| Dedicated for | Container | Weight | Diameter |

|---|---|---|---|

| Endureal | spool | 330 g ± 5% | 1.75 mm |

| Support material compatible with |

|---|

| BASF Ultrafuse® 17-4 PH, BASF Ultrafuse® 316L |

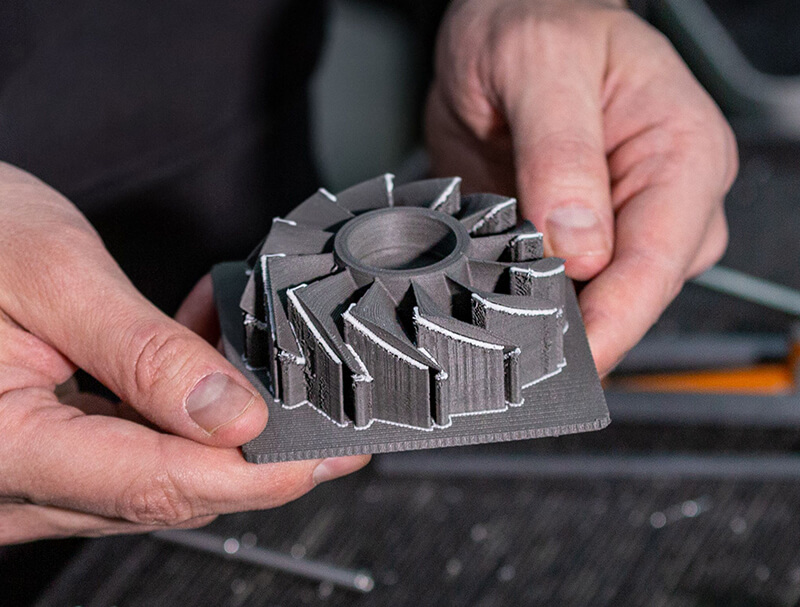

A steel turbine rotor beofre debinding and sintering process 3D printed on the Zortrax Endureal using Zortrax Full Metal Package 316L.

BASF Ultrafuse® 316L and BASF Ultrafuse® 17-4 PH

are two available metallic powder filaments corresponding to two types of steel. Here's how they are different.

| Type of steel | Corrosion Resistance | Structure | Mechanical performance |

|---|---|---|---|

| 316L | Stainless | Non-magnetic | Medium harndness / high elongation |

| 17-4 PH | Corrosive | Magnetic | High hardness / low elongation |

| Type of steel | 316L | 17-4 PH |

|---|---|---|

| Corrosion Resistance | Stainless | Corrosive |

| Structure | Non-magnetic | Magnetic |

| Mechanical performance | Medium harndness / high elongation | High hardness / low elongation |

Working with 316L steel prints

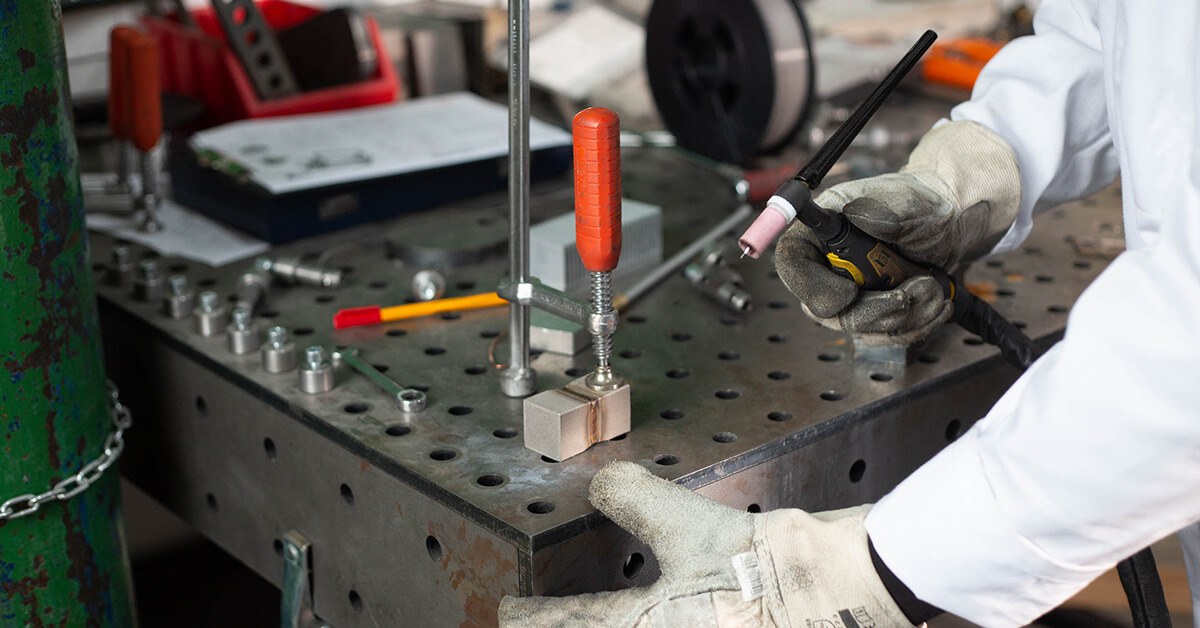

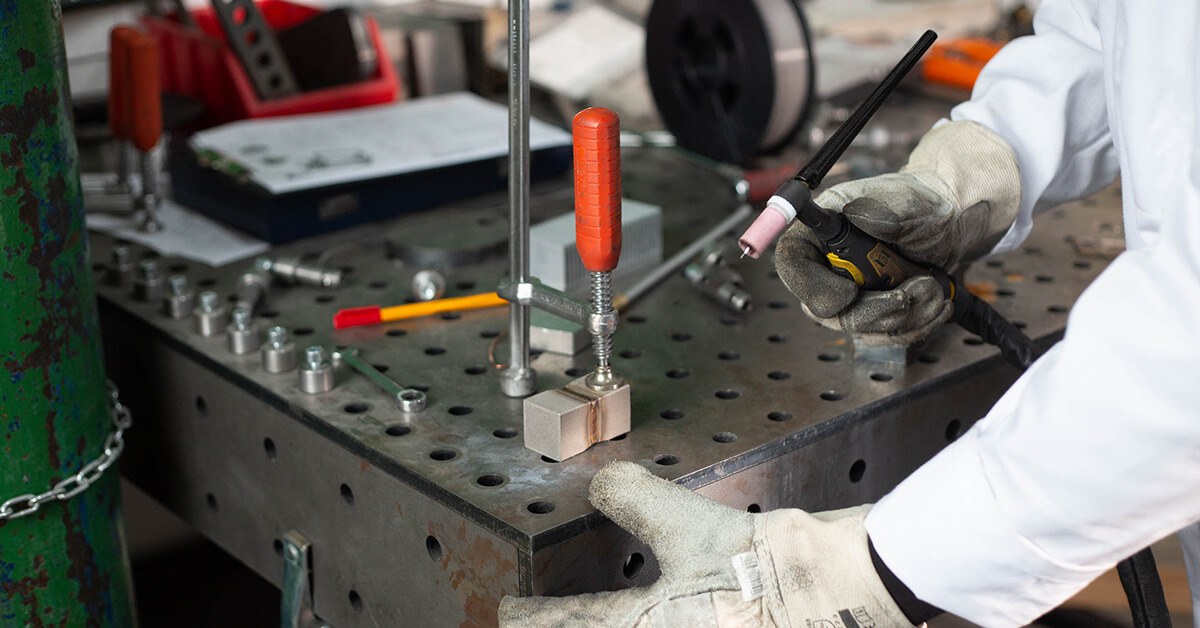

Welding: Parts made with Zortrax Full Metal Package 316L can be welded just like standard steel.

Polishing: Parts made with Zortrax Full Metal Package 316L can be polished or sanded to fine tune the dimensions or achieve mirror surface finish.

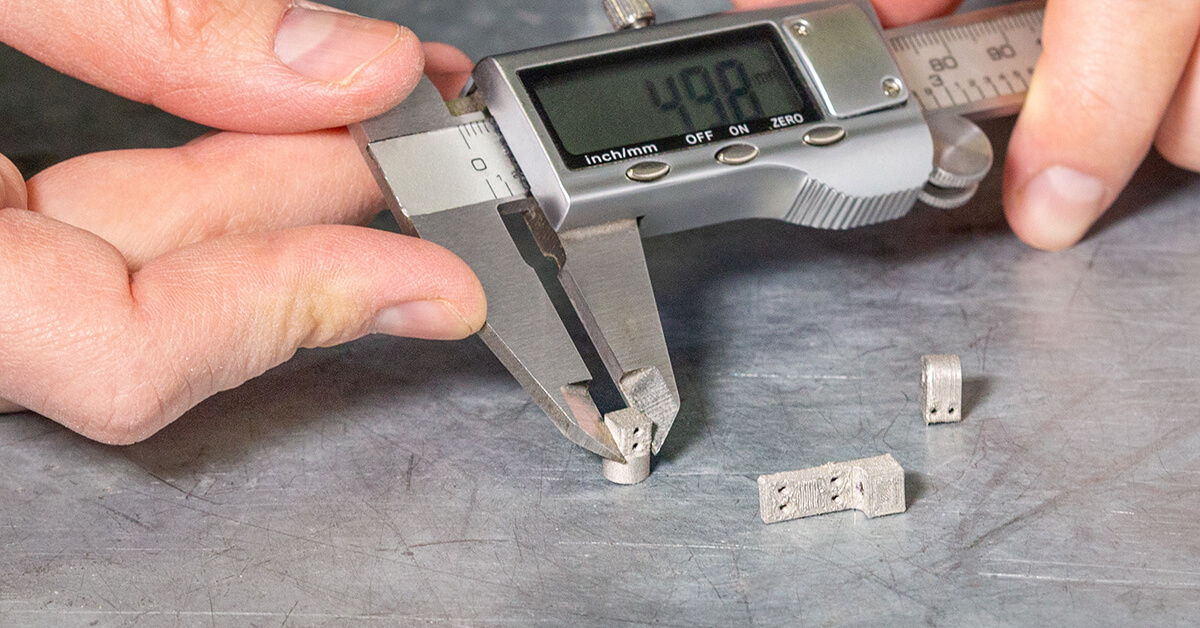

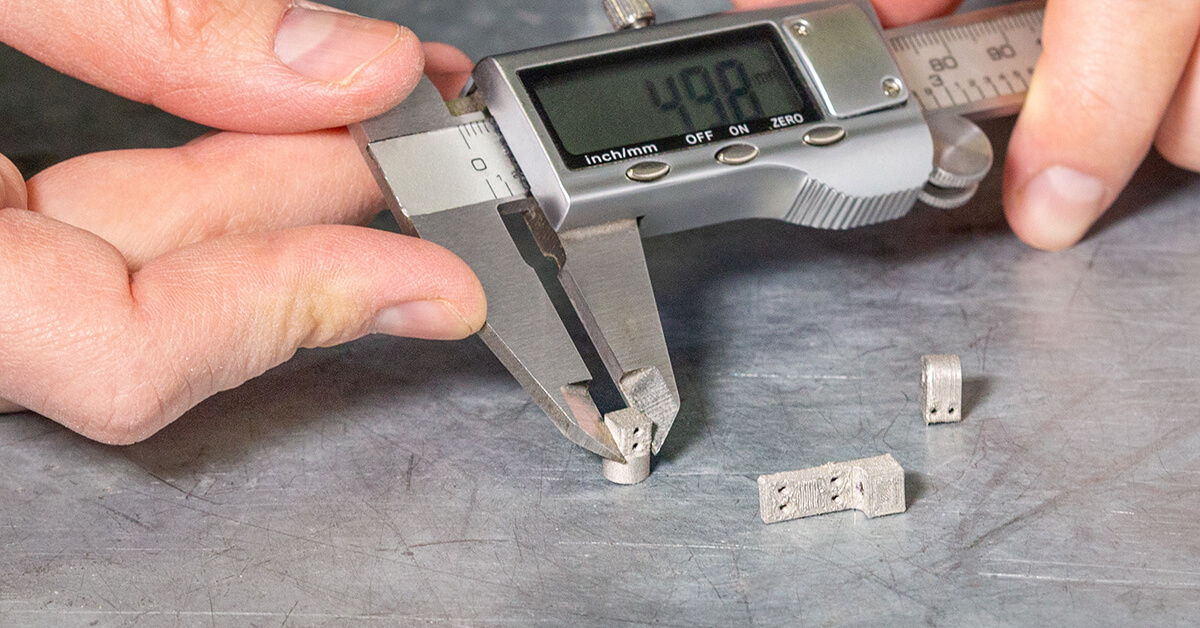

Zortrax Full Metal Package 316L works well even in manufacturing small, precise components.

Zortrax Full Metal Package 316L works best in producing steel parts that are too expensive or infeasible to make with standard steel processing techniques.