Forward AM Ultrafuse® PP GF30 is a polypropylene-based composite filament reinforced with a 30% addition of glass fiber. It is one of the most frequently selected materials in various industries, especially in the automotive sector. It is characterized by extremely high stiffness and resistance to heat, UV light, and chemicals.

This industrial-grade filament is incredibly lightweight and provides high dimensional accuracy to printed parts. It will work best when printing functional prototypes intended for demanding tests in unfavorable and humid environment. In addition, the filament is perfect for printing structural items as well as tools and fixtures.

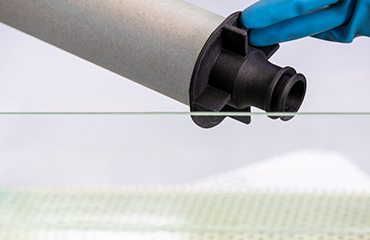

Forward AM Ultrafuse PP GF30 has strong abrasive properties, therefore, a hardened steel nozzle with a diameter of 0.6 mm should be used when 3D printing.