Demonstrator Made on Zortrax Endureal 3D Printer Will Fly to Space in WISA Woodsat Mission

3D printed electrical circuit made on Zortrax Endureal will be tested onboard the WISA Woodsat CubeSat scheduled for launch towards the end of 2021.

Read MoreAdditive manufacturing provides a unique set of capabilities no other manufacturing technology can match.

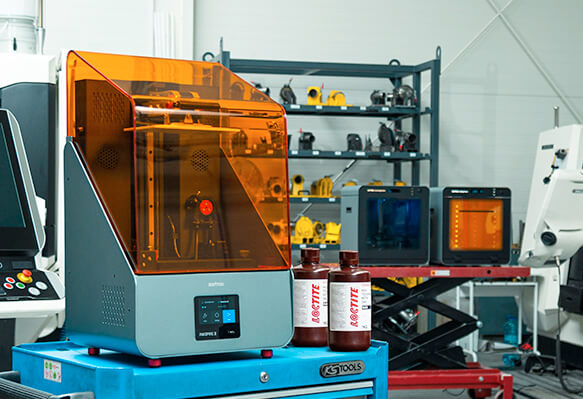

Zortrax 3D printers are compatible with a range of high-quality printing materials from world-leading manufactures like Forward AM, Henkel/Loctite, Victrex, Nanovia or 3DXTech.

These materials can be used for basic prototyping, manufacturing of durable end-use parts, or for making high-performance components meeting strict aerospace or defense industry standards.

Space is an extremely challenging environment which necessitates high-performance materials that retain their properties in a wide range of temperatures.

Space-grade parts are therefore usually 3D printed on industrial machines like Zortrax Endureal which can work with thoroughly tested high-performance, polymers.

Flightworthy parts in aviation are usually printed on industrial machines like Zortrax Endureal out of materials that meet aerospace flammability standards like Z-PEI 9085. Such parts are usually used to rapidly fabricate aircraft interior components that need to be replaced in older vessels when an aircraft is due for mandatory maintenance.

Jigs, fixtures and custom equipment for ground support applications, on the other hand, are often printed on more affordable 3D printers like Zortrax M300 Dual using more cost-efficient materials like Z-ABS.

3D printers in defense industry are used for prototyping and producing end-use parts in new equipment undergoing tests in the military.

Such 3D printed equipment is often used to adapt existing weapon platforms to work with new types of armaments.

The combination of desktop and industrial 3D printers with post-processing devices allows you to create an independent and remotely managed production system that can work in a variety of conditions, regardless of external supply chains.

Extrusion-based 3D printers are a perfect solution for workshops seeking to use cost-efficient 3D printing capabilities, rapid prototyping and on-the-fly design adjustments. Zortrax offers desktop and industrial 3D printers working in single or dual-extrusion technology:

UV LCD is a photopolymer resin 3D printing technology that works with outstanding precision and speed. Zortrax offers a complete resin 3D printing ecosystem with 3D printer and post-processing devices:

Z-SUITE 3D printing software with printing profiles for all supported materials and free Over-The-Air updates.

Covers stationary service and DIY repairs with technician online assistance

Time-saving system for efficient managing of your 3D printers.

Fully equipped Starter Kit with necessary consumables.

Schedule an individual teleconference session with Zortrax representative to learn how Zortrax 3D printers may improve your business.

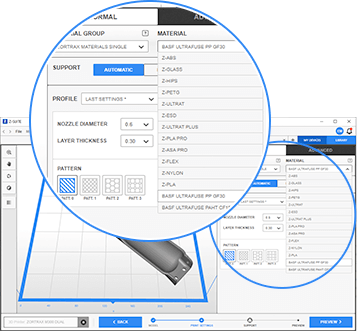

Contact usZ-SUITE is a powerful 3D printing software developed from the ground-up by Zortrax. 3D printable designs can be easily exported to it from CAD software like AutoCAD, Autodesk Fusion 360, or SolidWorks. Z-SUITE comes free with every Zortrax 3D printer. It is compatible with 3D printing materials offered by both Zortrax and external suppliers.

Learn more

Z-SUITE comes equipped with an extensive base of thoroughly tested printing profiles for each supported material coming either from Zortrax or one of its trusted suppliers. Using those printing profiles guarantees best possible results when printing with supported materials.

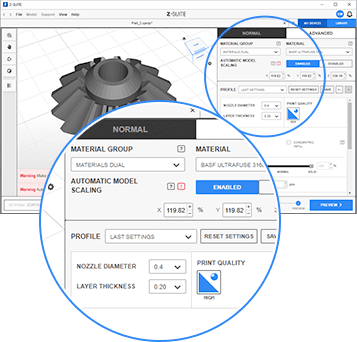

Metal 3D printing requires rescaling of the printed models to account for shrinkage happening at the post-processing stage when the printed model is turned into steel. Z-SUITE does the scaling automatically to ensure the dimensions of steel parts are exactly as specified in the part`s design.

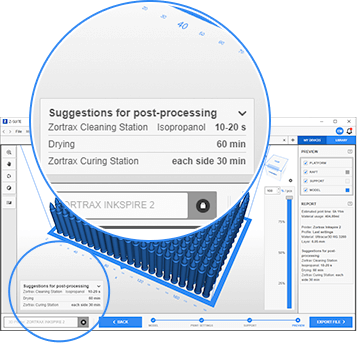

3D printing with photopolymer resins is a process that requires cleaning and curing 3D printed parts. Z-SUITE has built-in post-processing suggestions explaining what exactly has to be done to achieve target mechanical and thermal properties in the resin 3D printed part.

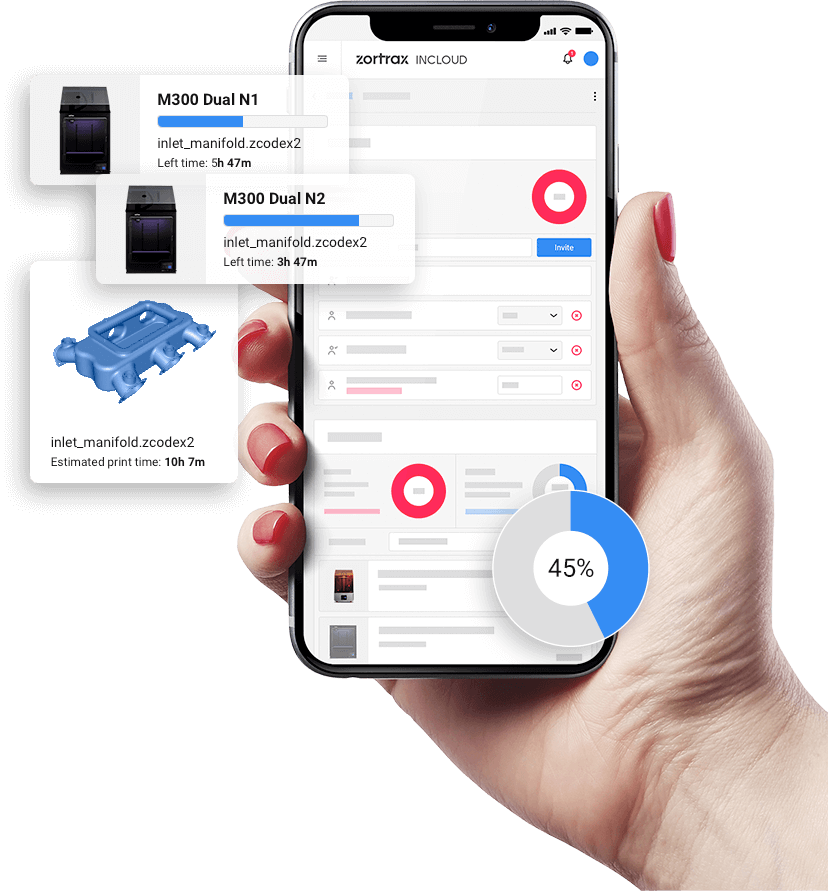

Zortrax inCloud is a cloud-based platform designed for remote management of available 3D printing staff and equipment.

Printing of a single model can be simultaneously started at all Zortrax 3D printers connected with the inCloud account.

With inCloud it is possible to remotely manage large clusters of Zortrax 3D printers. Each device in a cluster can be controlled individually even if each works in a different place.

Zortrax inCloud operates using servers located in the Zortrax HQ in Poland which means users data is processed and hosted in a safe location in the European Union.

inCloud platform has been developed entirely by Zortrax which means it can be tailored to individual customers need if necessary.

Learn more about implementing Zortrax 3D printing solutions from case studies done with Zortrax customers.

news 4D Printing Breakthrough Achieved in ESA-Funded Project

user-stories Prototyping Tools for Spacewalks—How Zortrax Ecosystem Works at NASA

products Zortrax Z-PEEK filament certified by European Space Agency

user-stories Quandum Aerospace Experience with Zortrax Inkspire 2 Resin 3D Printing Ecosystem

Fill in the short form below and we will get in touch to help you build the right 3D printing system for you needs.

Our representative will contact you shortly.