How 3D printers improve jewelry casting

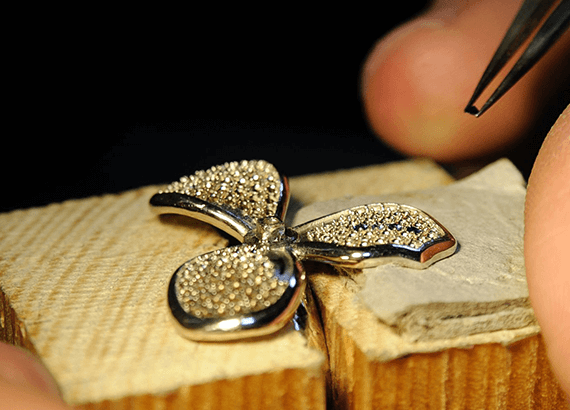

A jewelry piece casted with a 3D printed investment pattern.

Jewelers face three major challenges in their work

-

Customers expect their jewelry to have exclusive look and feel

-

Traditional jewelry making techniques are time-consuming and hard to master

-

Each change in the design requires a new investment pattern

Simpler workflow

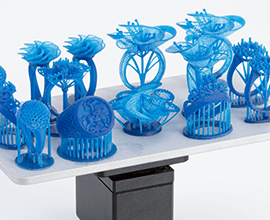

An entire jewelry casting tree can be 3D printed in a matter of hours with no need for a traditional, multi-stage assembly process.

Less human labor

A resin 3D printer can produce multiple jewelry casting trees in a single day making the process less labor-intensive and more cost-efficient.

Intricate details

Desktop resin 3D printers can work with microscopic precision, so small yet intricate features can be included in jewelry designs.

Easy implementation

High quality castable resins have physical properties nearly identical to wax, so they can be processed with the same set of tools and used with the same investments.

Workflow in jewelry making with resin 3D printers

Jewelers can implement implement resin 3D printers following four simple steps. Here's how it works.

Step 1: Prototyping

Multiple iterations of a design are 3D printed with standard resin.

Step 4: Casting

The pattern is used to make a mold for the target material.

Step 2: Fitting

3D printed models are used for fitting and gathering customer's feedback.

Step 3: Investment pattern

Castable resin is used to 3D print an investment pattern of the final design.

Step 1: Prototyping

Multiple iterations of a design are 3D printed with standard resin.

Step 2: Fitting

3D printed models are used for fitting and gathering customer's feedback.

Step 3: Investment pattern

Castable resin is used to 3D print an investment pattern of the final design.

Step 4: Casting

The pattern is used to make a mold for the target material.

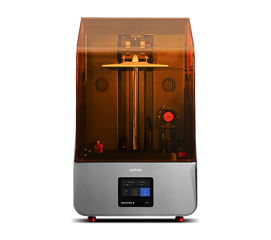

Resin 3D printer at a jeweler's workshop

Resin 3D printers working with castable resins improve productivity without disrupting established processes in jewelry

Some castable resins can be hand-shaped after printing to achieve intended level of detail

Resin 3D printers are precise enough to print inticate, filigree desings out of castable resins.

3D printed patterns have the same burnout properties as wax.

Resin 3D printers can print even relatively large desings.

Multiple models can be printed in one printing session.

3D printing technologies for jewelry making

Jewelers typically use a resin 3D printing technology like Zortrax UV LCD with different photopolymers chosen based on the design's features.

Filigree designs

Intricate light-weight middle-eastern style jewelry is made with highly precise cartable resins like BlueCast LS Original.

See more

Small designs

Small designs like engagement rings are made with dimensionally accurate castable resins like BlueCast X5

See more

Large designs

Investment patters of large designs need resins like BlueCast X10 that combine smooth surfaces with excellent burnout properties.

See more

Precise models

The UV LCD technology in Zortrax Inkspire is considered the most suitable for jewelry casting due to its high precision and speed.

See moreUser stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.