Why rapid prototyping is good for business

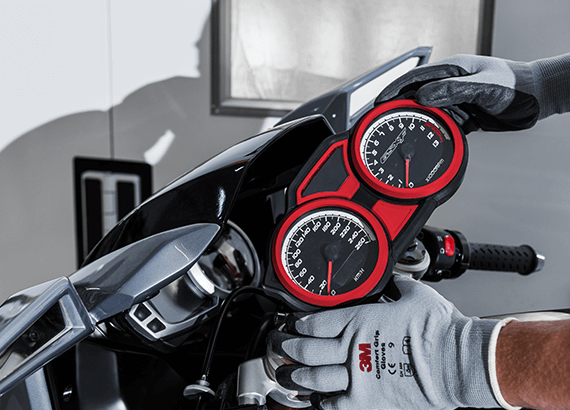

3D printed motorcycle gauges.

Rapid prototyping is an answer to three major challenges businesses face in product development

-

Iterating through multiple version of a design takes a lot of time and resources

-

Outsourcing fabrication of prototypes comes with a risk of having the design leaked

-

Using traditional manufacturing technologies for prototyping lengthen the time to market

No lead times

R&D staff can iterate through different designs rapidly which make their work more efficient.

In-house fabrication

Prototypes are made entirely in-house which contributes to better intellectual property protection.

Short time to market

Fast and efficient prototyping stage leads to shorter time to market, so a new product can bring in revenue sooner.

Limitless design

3D printing is capable of producing shapes impossible to make with traditional manufacturing techniques.

Workflow in rapid prototyping

Modern rapid prototyping is done in four simple steps. Here's how it works.

Step 1: CAD design

A new product is designed in a CAD software.

Step 2: Digital pre-processing

A set of instructions for the 3D printer is created based on the CAD model.

Step 4: Evaluation

A physical prototype can be used for testing or presented to stakeholders.

Step 3: 3D printing

A model is automatically fabricated on a 3D printer.

Step 1: CAD design

A new product is designed in a CAD software.

Step 2: Digital pre-processing

A set of instructions for the 3D printer is created based on the CAD model.

Step 3: 3D printing

A model is automatically fabricated on a 3D printer.

Step 4: Evaluation

A physical prototype can be used for testing or presented to stakeholders.

Technologies for rapid prototyping

The choice of the right 3D printing technology for rapid prototyping depends on the kind and size of products under development.

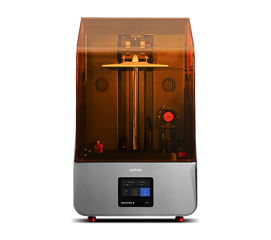

Precise engineering and electronics

Resin 3D printing technologies like the Zortrax UV LCD are best for prototyping small yet complex products.

See more

Medium size products with simple geometry

LPD technology is the most cost-efficient for prototyping medium size simple products like lamps or remote controllers.

See more

Medium size products with complex geometry

LPD Plus technology is best for intricately designed, medium size parts like movable mechanism or organic shapes.

See more

High-quality exposition prototypes

SVS automated post-processing devices can be used with LPD or LPD Plus printers to make prototypes meant for trade fairs or stakeholders' meetings.

See moreUser stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.