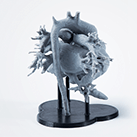

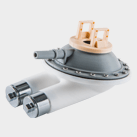

For 3D printing

moving mechanisms

Zortrax Inventure can 3D print movable mechanisms in one go. The heated chamber keeps the right temperature to minimize shrinkage and achieve high dimensional accuracy. Soluble support structures can be removed from between tightly interlocked parts just by rinsing the model in water.