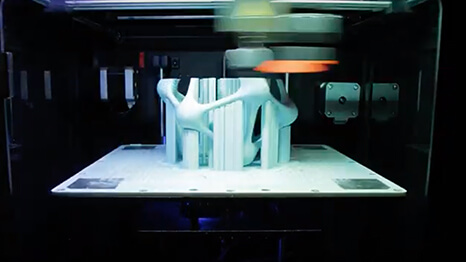

Step 1 Print

Print the models on any FDM, FFF, or LPD 3D printer.

Zortrax Apoller is a desktop smart vapor smoothing device offering industrial class performance. Every aspect of a smoothing process is managed by proprietary algorithms to get the looks of FDM 3D printed models on par with injection molded items.

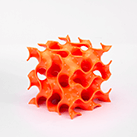

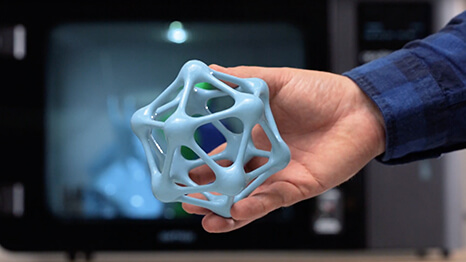

Smart Vapor Smoothing (SVS) technology evenly smooths surfaces on all kinds of models, including those with complex geometries and interlocked movable parts. It's done through automatic management of temperature, pressure, and concentration of solvent's vapors in the Apoller's smoothing chamber.

Zortrax Apoller can smooth models printed on all FDM, FFF, LPD, and LPD Plus 3D printers. The device is compatible with filaments based on ABS, HIPS, and ASA, regardless of their manufacturer. Just remember to use only pure acetone or pure MEK as solvents.

3D printing farms can cost-efficiently deal with low to medium scale production by moving it in-house and making on-the-fly adjustments possible. Complemented by Apoller post-processing devices, they can now offer products' quality on par with injection molding.

Contracting external suppliers, almost no room for adjustments, and high cost per unit are among major issues with low-scale production because the economy of scale is not yet there to bring the prices down. Once significant resources are invested in making injection molds for a new product, a business is basically all-in.

Automated vapor smoothing is simple and safe enough to be performed by untrained staff.

Print the models on any FDM, FFF, or LPD 3D printer.

Place the models in the chamber, close the door, and choose the smoothing settings on a touch screen.

The Apoller does all the rest on its own. After 3h models are smoothed and ready to use.

The vacuum system in Zortrax Apoller prevents the pressure inside the smoothing chamber from getting higher than the pressure outside of it even after the solvent has been vaporized. That's why the vapors are kept inside the chamber instead of being pushed out of it.

The vapors in the Zortrax Apoller smoothing chamber ar circulated upward to evenly cover the models. Fragile and intricate details are covered with less solvent to keep their shape intact. Once it's done, the condensation system retrieves the excessive solvent that can be reused.