Forward AM Resins Validated on Zortrax Inkspire 2

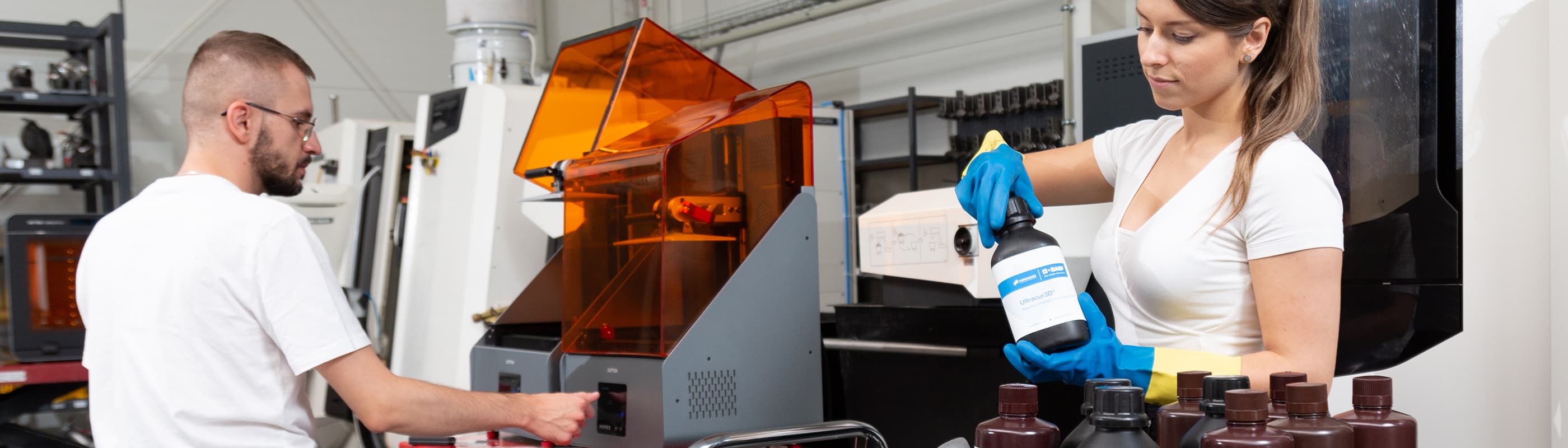

Forward AM is one of the largest manufacturer of photopolymer resins in the world offering a wide range of materials dedicated for UV LCD, DLP, and SLA 3D printers. Working with Forward AM, Zortrax engineers developed printing profiles that guarantee getting the most out of Forward AM's most advanced resins on the Inkspire 2. Each Forward AM material supported on the Inkspire 2 has been put through a strict, two-stage validation process to make sure that mechanical and thermal properties of 3D printed parts meet or exceed the values declared by the manufacturer. This process is performed at Zortrax headquarters and at Forward AM 3D printing laboratories independently and included 3D printing of parts on the Inkspire 2 and post-processing them in Zortrax Cleaning Station and Zortrax Curing Station.

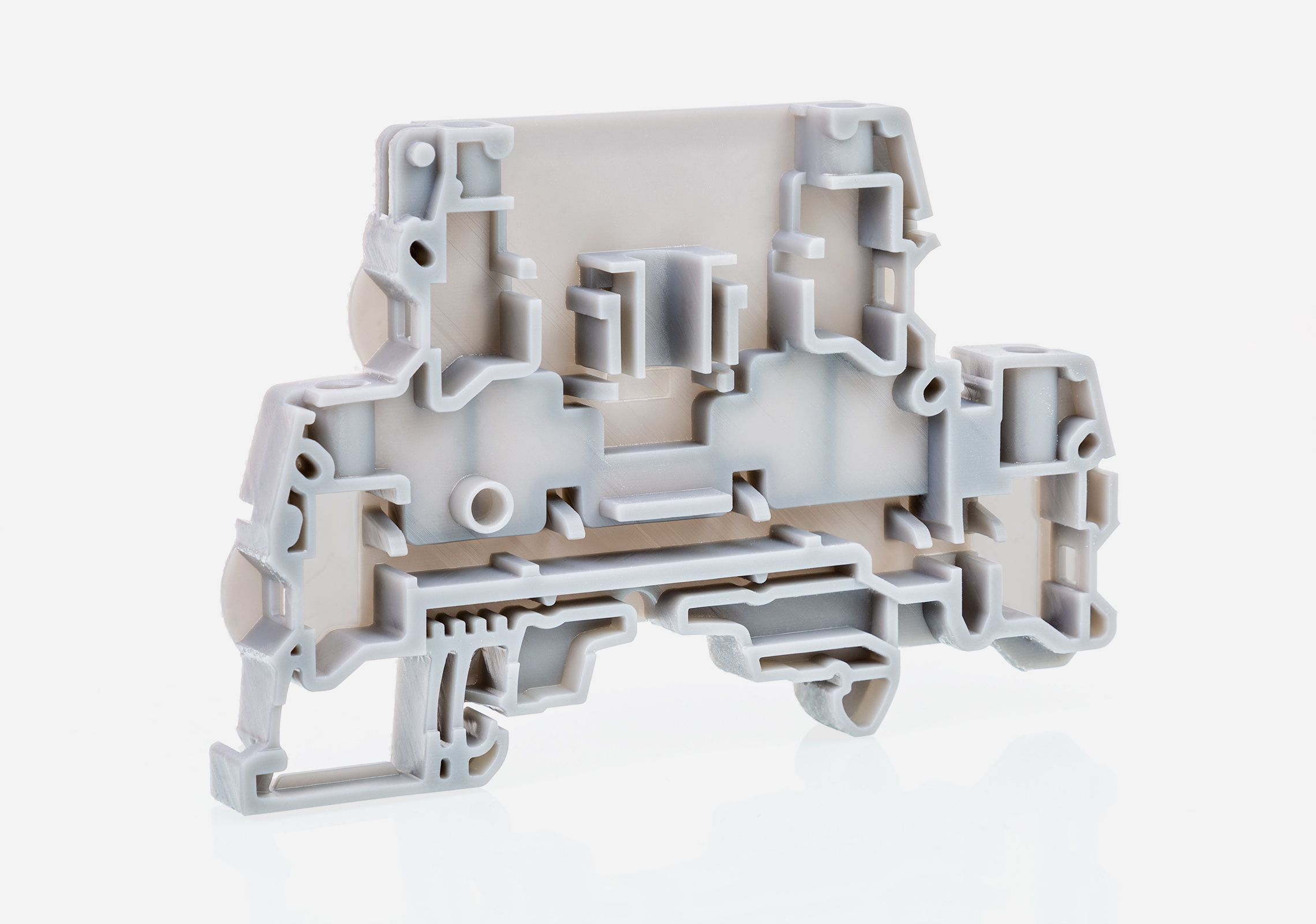

High rigidity resins

The defining feature of these materials is high rigidity. Parts 3D printed with rigid resins do not give way under stress, retaining their shape to the point of breaking. They work best in structural frames, positioning jigs, or fixtures.

Applications

Structural frames

Positioning jigs

Fixtures

Casings

Key benefits

High stiffness

High accuracy

Low shrinkage

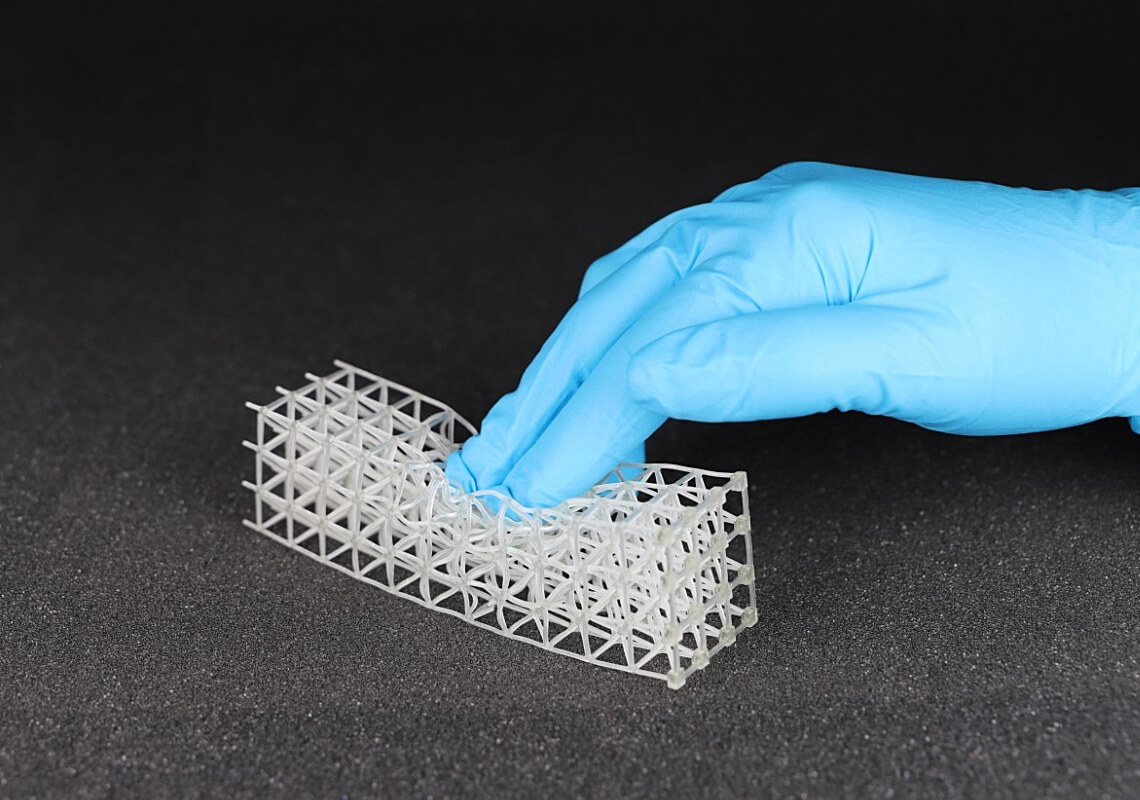

Tough resins

Tough resins can endure very high loads before they break. Compared to rigid materials, they give way a little bit sooner under stress but need higher force to reach the breaking point. As such, tough resins are usually used for mechanical components working under significant loads.

Applications

Load-bearing components

Impact-resistant components

Wear and tear resistant components

Key benefits

High mechanical strength

High impact-resistance

Resistance to wear and tear

Elastomeric resins

The purpose of elastomeric resins is emulating various kinds of rubber. Such materials are commonly used for seals, gaskets, or hinges. They differ by the degree of elasticity, mechanical strength, and thermal properties to fit wide range of engineering needs.

Applications

Gaskets

Hinges

Shock-resistant bumpers

Key benefits

Very low hardness

High elongation at break

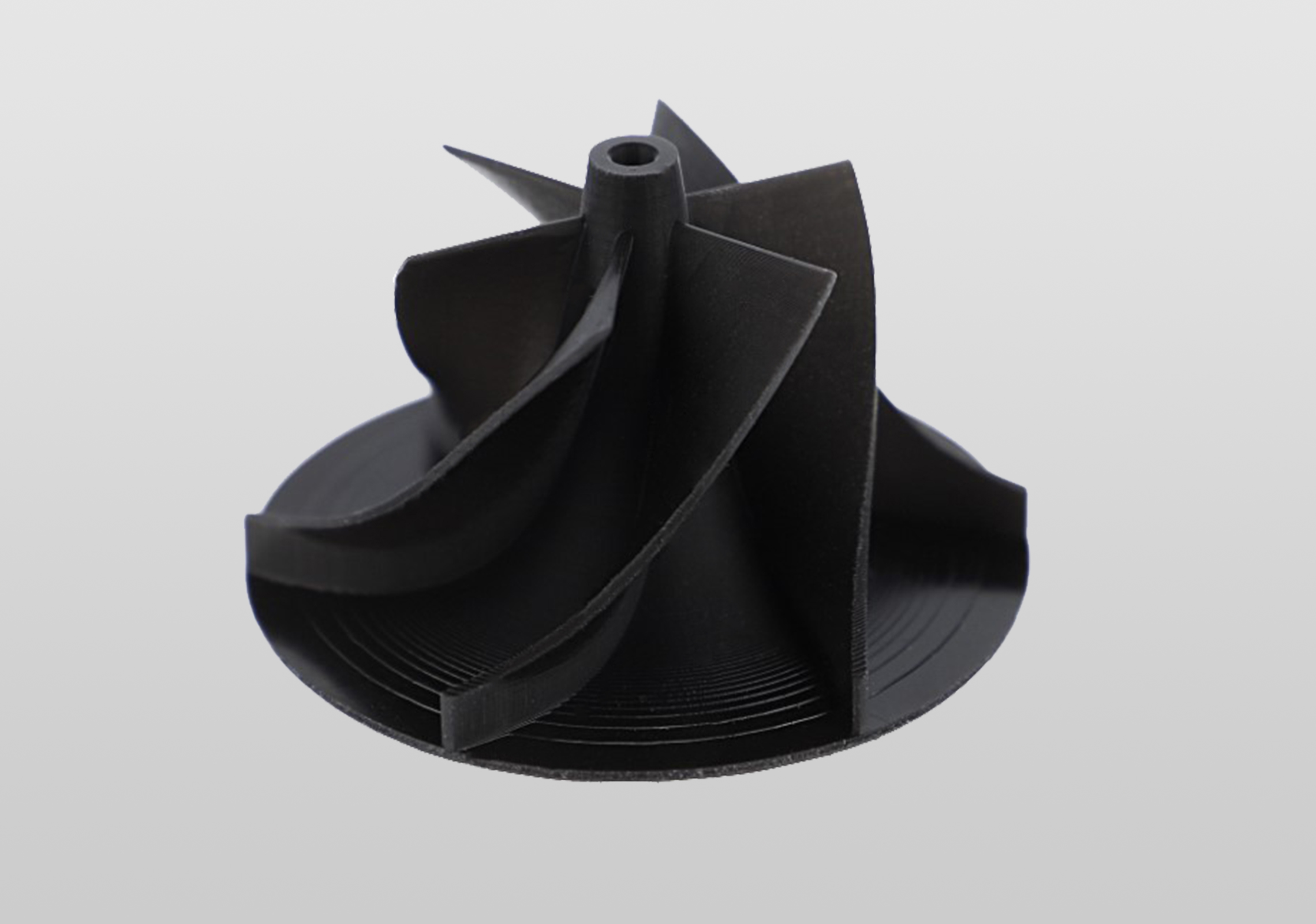

High-temperature resins

High-temperature resins can withstand exposure to high temperatures without loosing their mechanical properties. Such materials are used to quickly 3D print molding-grade components or to fabricate parts operating in high-temperature environments.

Applications

Molding-grade parts

Components working in high temperature environments

Key benefits

High Heat Deflection Temperature

Thermal stability

Mechanical strength

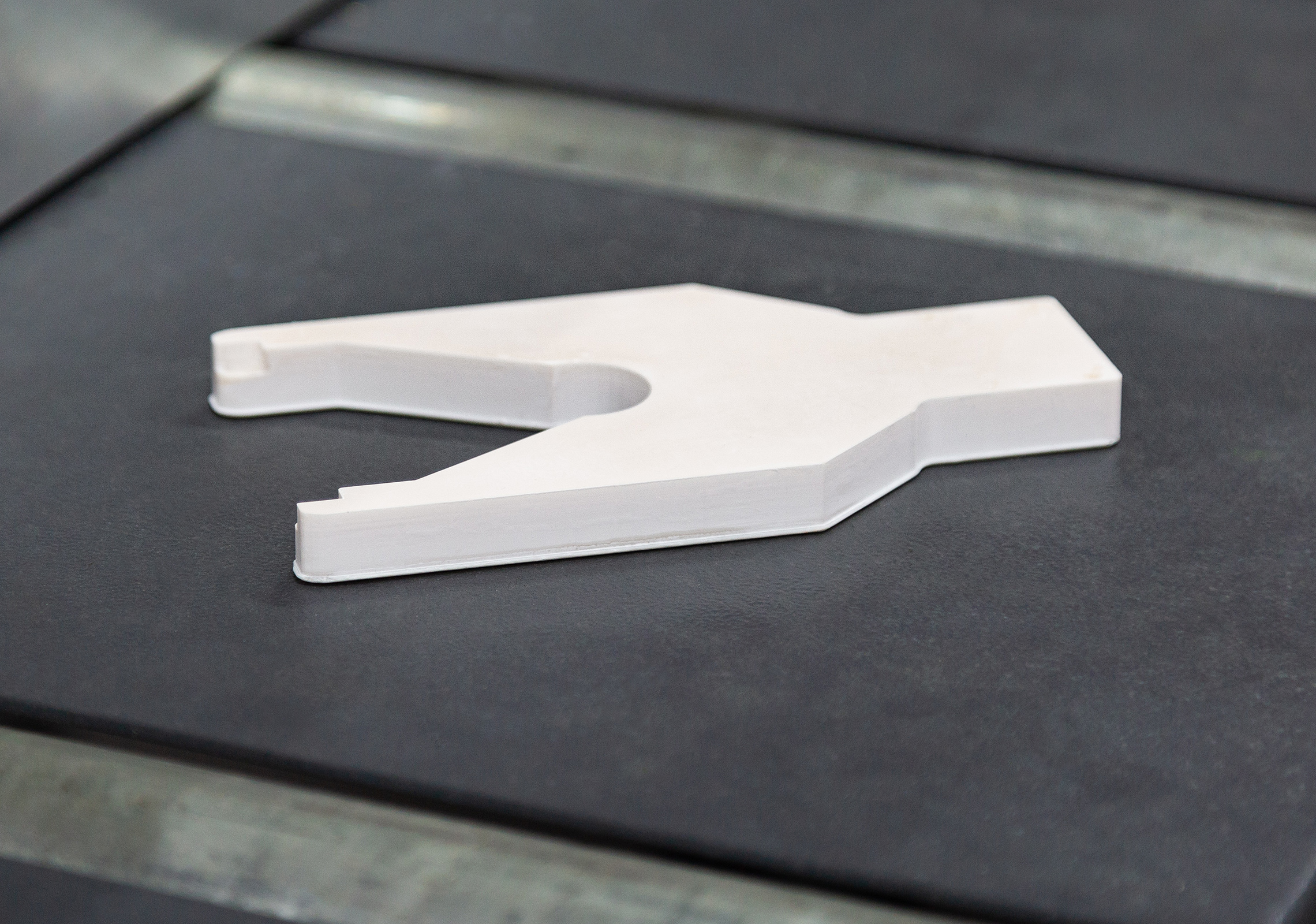

Ceramic-Filled Resin

Specialized, ceramic-filled resin belonging to the rigid line of Forward AM’s 3D printing photopolymers. High content of ceramic particles makes the material desirable in the automotive, robotics, electronics, metallurgy, energy production and chemical industry.

Applications

Molding-grade parts

Wear and tear resistant components

Key benefits

High heat deflection temperature

High stiffness

Thermal stability