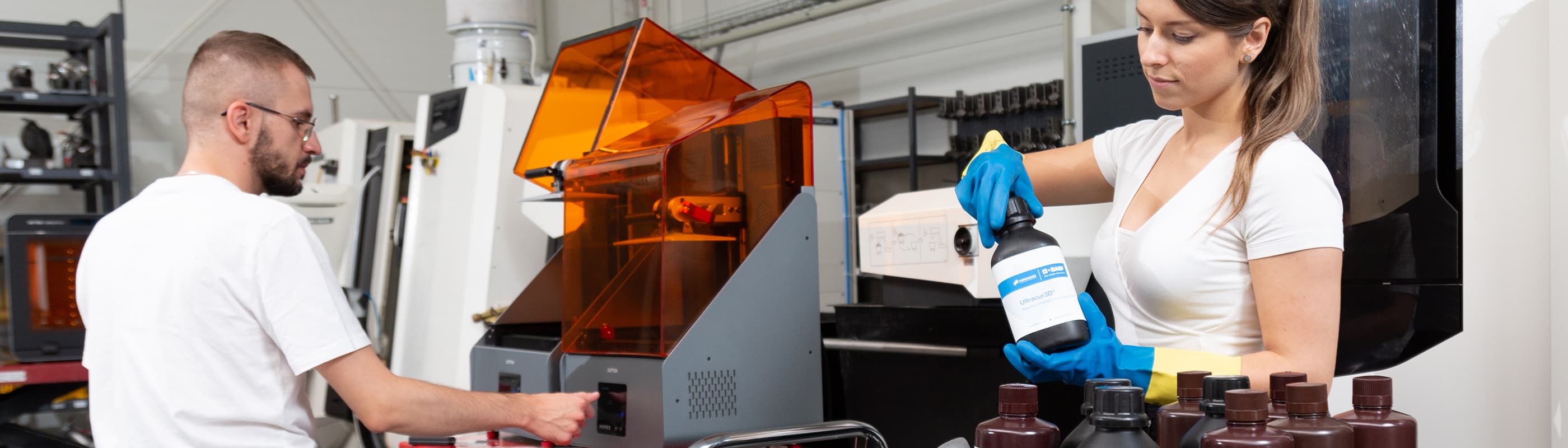

Ultracur3D® RG 3280 is a specialized, ceramic-filled resin belonging to the rigid line of BASF Forward AM’s 3D printing photopolymers. It is suitable for printing on Zortrax Inkspire 2 with 405 nm wavelength and post-processing in Zortrax Cleaning Station and Zortrax Curing Station. The material is characterized by exceptionally high stiffness reaching 10 GPa and excellent resistance to high temperatures with HDT of up to 280 ºC at 0.45 MPa.

Despite the specific composition, the resin has a low viscosity and its sedimentation is limited. As a result, the resin is less likely to settle at the bottom of the vat and it is easy to process and print. High content of ceramic particles makes Ultracur3D® RG 3280 desirable in the automotive, robotics, electronics, metallurgy, energy production and chemical industry. The resin is white and has a ceramic look to it.

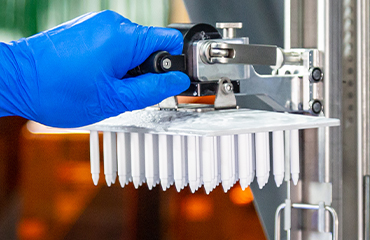

3D prints made with Ultracur3D® RG 3280 on Zortrax Inkspire 2 and properly post-processed in Zortrax Cleaning Station and Zortrax Curing Station do not require any further thermal processing. The whole procedure using these three devices lets you obtain parts with properties similar to ceramics without the need to use special furnaces.