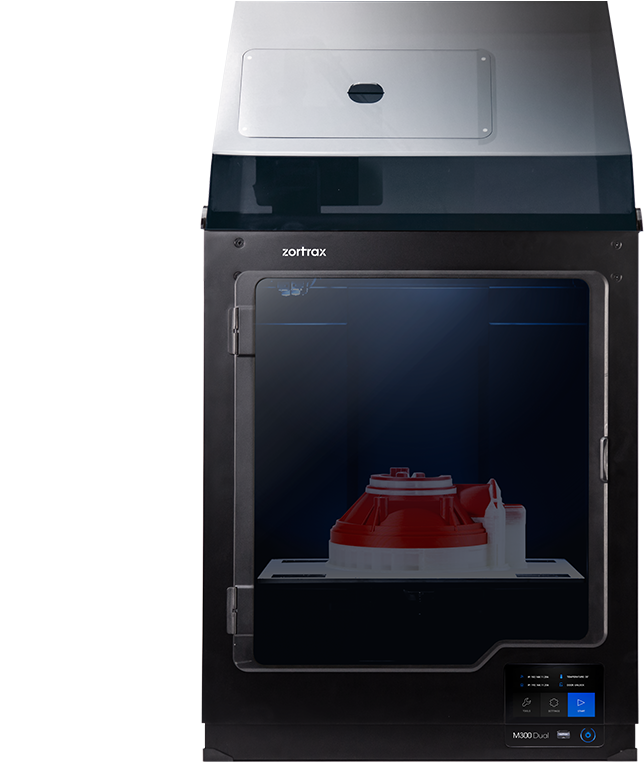

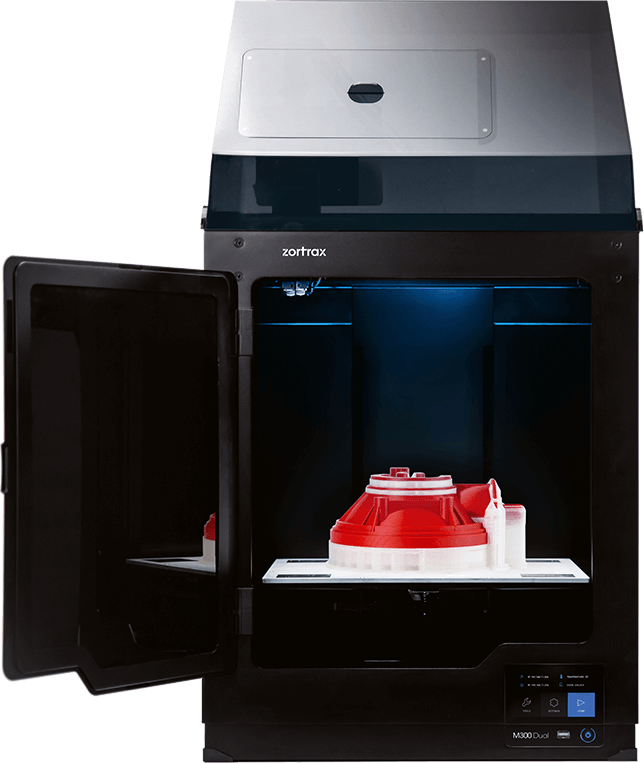

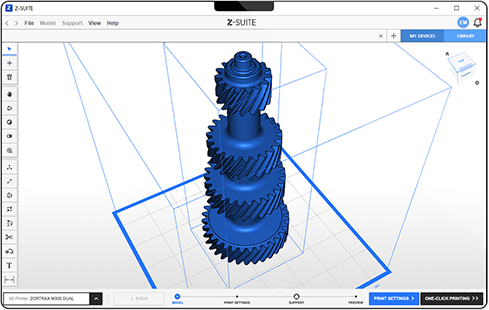

Dedicated for single extrusion

Z-ABS, Z-ASA Pro, Z-ESD, Z-FLEX, Z-GLASS, Z-HIPS, Z-NYLON, Z-PETG, Z-PLA, Z-PLA Pro, Z-ULTRAT, Forward AM Ultrafuse® PAHT CF15, Forward AM Ultrafuse® PP GF30, Forward AM Ultrafuse PET CF15, 3DXTECH CarbonX PETG+CF, Kimya PETG Carbon, Nanovia PC-ABS V0, Nanovia PETG CF

Dedicated for dual extrusion

Z-ABS, Z-ASA Pro, Z-ESD, Z-FLEX, Z-NYLON, Z-GLASS, Z-PETG, Z-PLA, Z-PLA Pro, Z-SUPPORT ATP, Z-SUPPORT Premium, Z-ULTRAT, Forward AM Ultrafuse 17-4 PH, Forward AM Ultrafuse 316L, Forward AM Ultrafuse ABS, Forward AM Ultrafuse BVOH, Forward AM Ultrafuse PAHT CF15, Forward AM Ultrafuse Support Layer, Nanovia PC-ABS V0

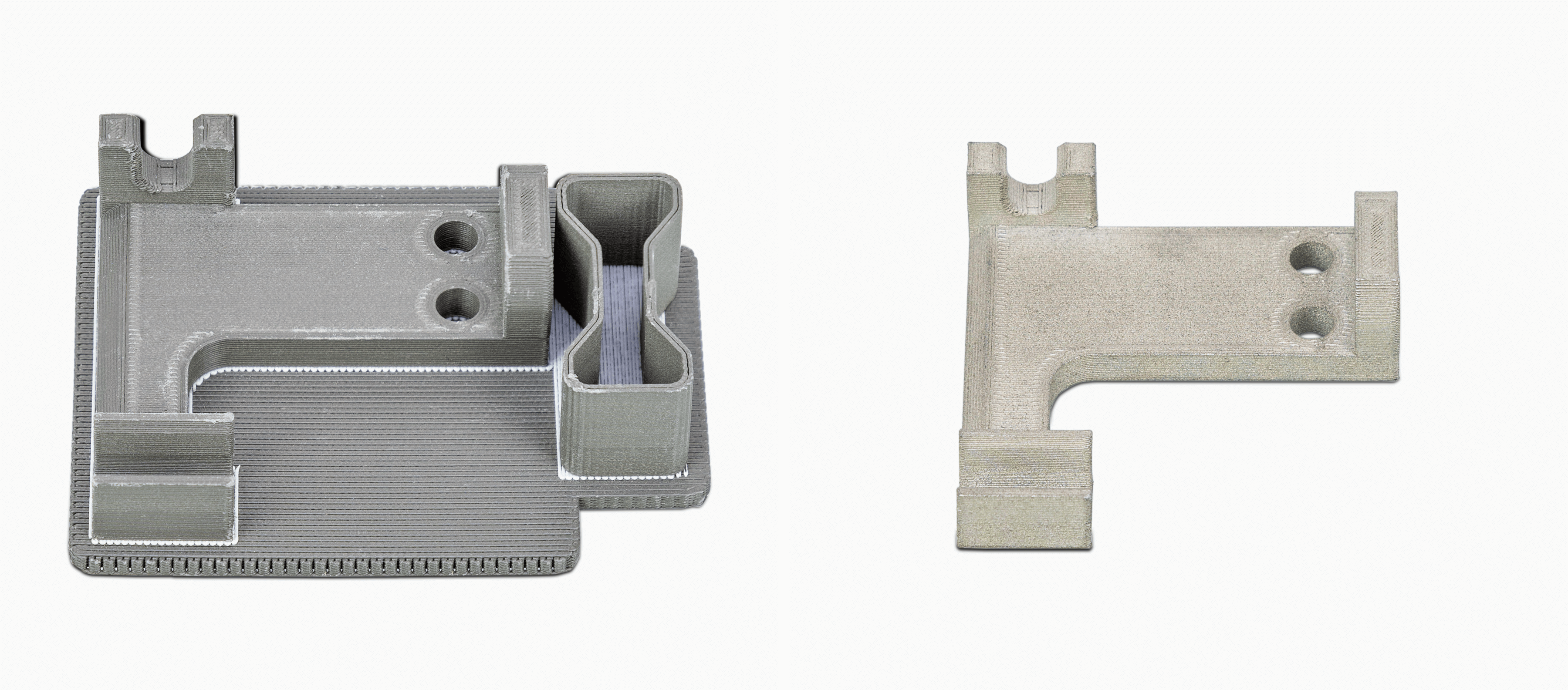

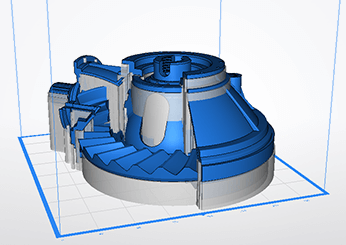

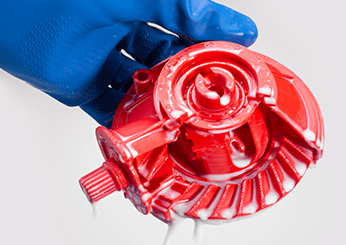

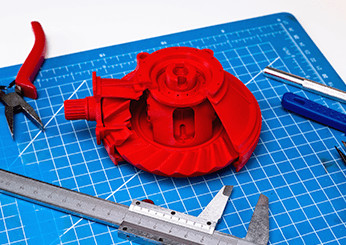

Support

Mechanically removed - printed with the same material as the model / Soluble – printed with a different material than the model