Z-ULTRAT Plus is a highly resilient ABS-based 3D printing filament. It’s perfect for functional prototypes or 3D printing complex moving mechanisms in one go. No matter the purpose, objects created with Z-ULTRAT Plus remain dependable through time. What’s more, this 3D printing material is unaffected by high temperatures and impacts. Its exceptional resilience allows for demanding tests conducted in adverse environments. The filament is also suitable for creating durable end-use parts for automotive industry and engineering purposes. Improved adhesion between layers reinforces 3D printed parts.

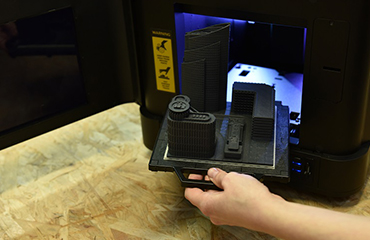

Combined with a water-soluble Z-SUPPORT Premium filament, Z-ULTRAT Plus is a reliable solution for 3D printing intricate, hollow objects. Dissolvable support structures allow stacking batches of parts on top of each other. This feature provides a fitting solution for cost-effective short-run production. Based on ABS, the material can withstand post-processing with acetone and mechanical treatment. Z-ULTRAT Plus 3D printing material is securely locked in a cartridge to ensure the highest quality of every print.