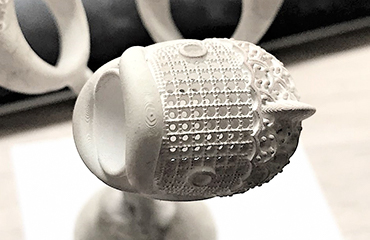

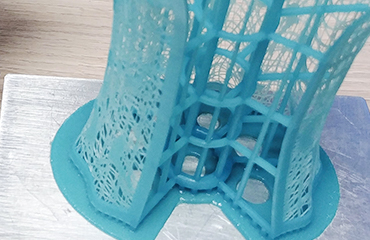

Advanced castable 3D printing resin designed to guarantee smooth surfaces and precise details in relatively big models. BlueCast X10 makes it possible to print jewelry pieces requiring large amounts of metal. It exhibits properties nearly identical to wax and thus can be processed with the same toolset.

Full burnout is possible at a relatively low temperature of 740° C. The resin requires post-curing only when post processing techniques like polishing are to be applied to the 3D printed pattern. Otherwise, post-curing is not necessary. Storing a pattern for 7 days causes a negligible 0.7% shrinkage which is particularly useful when patterns need to be made in advance.

*The resin can lose color when exposed to UV light. It is completely normal and does not affect its specified properties.