Z-PEI 9085 is a durable, aerospace-grade polymer with strength-to-weight ratio comparable to aluminum 6061. This filament consists of polyetherimide with a polycarbonate copolymer blend. Z-PEI 9085 exhibits excellent thermal properties and retains its properties in temperatures reaching 167 °C. The most notable property of Z-PEI 9085 is very low FST (Flame, Smoke, Toxicity). The material has a UL 94 V-0 flammability rating which makes it perfect for printing flame-retardant components.

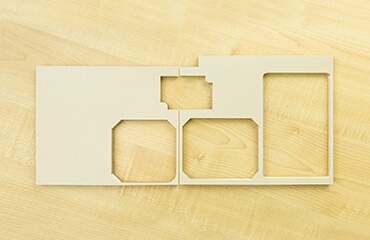

Due to certified flame retardancy, Z-PEI 9085 can be used to print ducting and panels for all scenarios where low-outgassing and low FST are necesary. The material also attenuates vibrations to a certain extent, so can be used for casing or structural frames protecting fragile components like electronics. This means that Z-PEI 9085 is a good match for:

- Aviation

- Space industry

- Marine industry

- Railroad industry

- Automotive industry

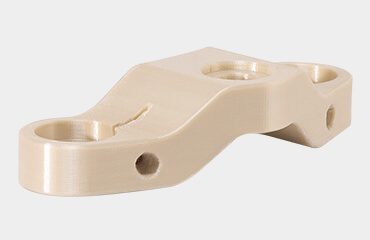

Exceptional mechanical and thermal properties are primary reasons why Z-PEI 9085 is widely adopted in automotive and aerospace industries. Flame retardancy of the material makes it suitable for fabricating aircraft interiors, ductwork, and electrical enclosures. What’s more, Z-PEI 9085 is resistant to automotive fluids and alcohols which enables printing tools that have to work with lubrication. Z-PEI 9085 is certified to meet FAR 25.853 standard accepted in the aerospace industry.