Introducing metal 3D printing

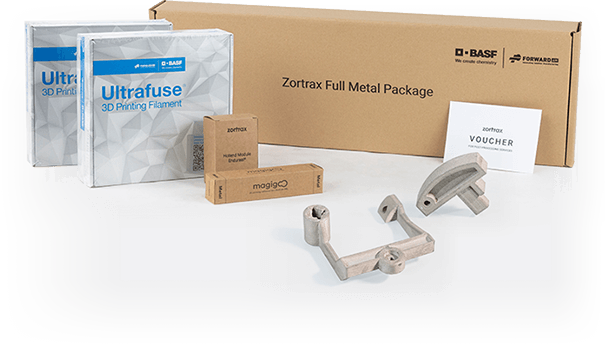

Working with Forward AM we've introduced Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH: kits that enable 3D printing models made of two most commonly used types of steel: 316L surgical-grade stainless steel and 17-4 PH hardened steel.

Here's all you need to know about precipitation hardened steel included in the Zortrax Full Metal Package 17-4 PH.

17-4 PH steel contains more carbon than the 316L grade which makes it significantly stronger and harder. But this higher percentage of carbon also makes it more brittle and prone to corrosion. 17-4 PH steel is used for:

- Petroleum industry parts

- Paper processing machinery

- Aerospace parts

- Structural frames

- Turbine blades

Parts made with Zortrax Full Metal Package 17-4 PH are isotropic and can be welded, polished or machined just like standard steel.

Zortrax Full Metal Package 17-4 PH contains everything you need to make parts out of hardened steel on the Zortrax M300 Dual 3D printer. The package includes:

- 1000 g spool of Forward AM Ultrafuse® 17-4 PH metallic powder filament

- A 300 g spool Forward AM Ultrafuse® Support Layer

- Magigoo® Pro Metal 50ml glue

- M300 Dual hotend module with steel nozzle

- PTFE tube with Adapter

- Post processing voucher for a 500 g of metal parts

- Bubble wrap to secure your 3D printed parts for transit

Forward AM Ultrafuse® 17-4 PH metallic powder filament and Forward AM Ultrafuse® Support Layer are available for purchase separately.

Zortrax Full Metal Package 17-4 PH contains everything you need to make parts out of 17-4 PH hardened steel on the Zortrax Endureal 3D printer. The package includes:

- 1000 g spool of Forward AM Ultrafuse® 17-4 PH metallic powder filament

- A 300 g spool Forward AM Ultrafuse® Support Layer

- Magigoo® Pro Metal 50ml glue

- Endureal hotend module

- Post processing voucher for a 500 g of metal parts

- Bubble wrap to secure your 3D printed parts for transit

Forward AM Ultrafuse® 17-4 PH metallic powder filament and Forward AM Ultrafuse® Support Layer are available for purchase separately.

How to use Zortrax Full Metal Package 17-4 PH

Printing

Green Part

Printing

Green Part

Debinding

Brown Part

Debinding

Brown Part

Sintering

Metal Part

Sintering

Metal Part

The process is simple. You replace a standard hotend module with the one included in the package, load the included printing and support filament, cover the build platform with included Magigoo Pro Metal glue, print your parts using default settings in Z-SUITE, send the parts for post processing using the included voucher, get your post-processed metal parts delivered to your doorstep. To make best possible metal parts with the Zortrax Full Metal Package 17-4 PH you need to follow a few simple guidelines and design principles. They are all clearly explained in our metal 3D printing step by step manual.

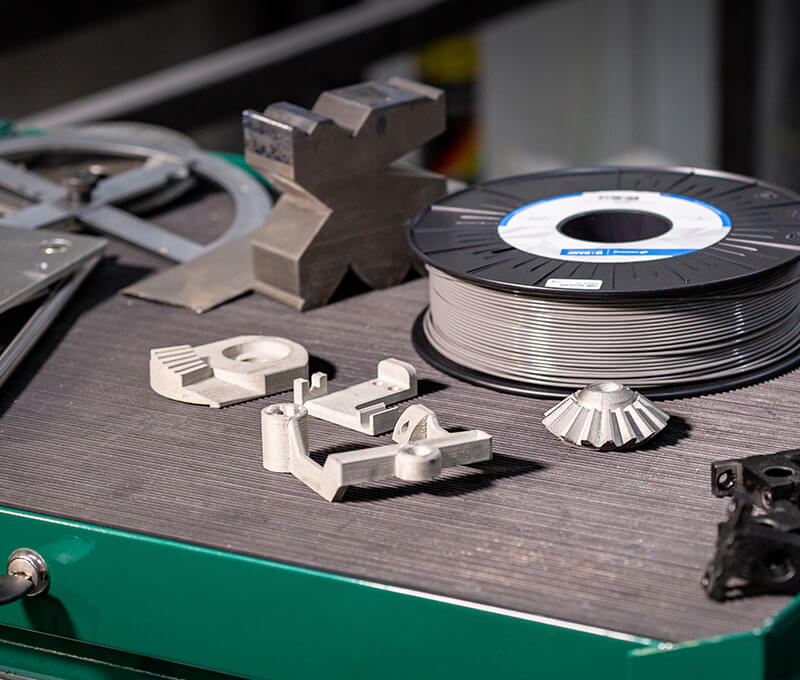

Forward AM Ultrafuse® 17-4 PH is an industrial composite filament compatible with the LPD Plus Zortrax Endureal 3D printer. It has features that allow users to produce metal parts in a safe, easy, and cost-effective way in comparison with Metal Injection Molding or metal machining. The filament contains 80% 17-4 stainless steel particles and 20% of polymer content.

Forward AM Ultrafuse® 17-4 PH can be used for 3D printing strong metal end-use parts, functional prototypes, elements requiring weather resistance, medical equipment, automotive parts, chemical pipes or valves, elements of tools or fixtures. Printed parts have up to 1004 MPa tensile strength, 764 MPa yield strength, up to 4% elongation at break, and have martensitic (magnetic) microstructure.

3D prints gain their unique properties through the proprietary catalytic debinding and sintering process, outsourced at Elnik Systems GmbH. During this process, 3D printed “green parts” turn into fully metal “brown parts.” As a result you receive magnetizable elements with high corrosion resistance. During the post-processing procedures, Forward AM Ultrafuse® 17-4 PH models shrink by about 20%. This effect should be taken into account when preparing models for 3D printing.

Available Colors

| Dedicated for | Container | Weight | Diameter | Extrusion |

|---|---|---|---|---|

| Zortrax M300 Dual | spool | 3000 g ± 5% or 1000 g ± 5% | 1.75 mm | Dual with Forward AM Ultrafuse® Support Layer |

| Zortrax Endureal |

| Key Properties | Metric | Imperial | Test Method |

|---|---|---|---|

| Tensile strength | 1004 MPa | 145.62 ksi | ISO 6892-1 |

| Yield strength | 764 MPa | 110.81 ksi | ISO 6892-1 |

| Elongation at break | 4% | 4% | ISO 6892-1 |

| Vickers hardness (HV10) | 309 | 309 | ISO 6507-1 |

Parts for printing with Zortrax Full Metal Package 17-4 PH should be designed to control for shrinkage in the post-processing stage.

Applications

- functional prototypes,

- metal end-use parts,

- elements requiring weather resistance,

- medical equipment,

- automotive parts,

- components for chemical industry,

- parts intended for welding,

- customized tooling, jigs, fixtures.

High hardness

Carbon additions and precipitation hardening process make 17-4 PH steel particularly hard.

High yield strength

17-4 PH can endure enormous loads before it deforms or cracks.

Low elongation

Low elongation means that 17-4 PH steel would break rather than bend under critical load.

Forward AM Ultrafuse® Support Layer

Forward AM Ultrafuse® Support Layer is a support filament dedicated for metallic powder filaments. Using it is crucial to achieve desired parts' geometry both during the 3D printing and post-processing stage.

Available Colors

| Dedicated for | Container | Weight | Diameter |

|---|---|---|---|

| Endureal | spool | 330 g ± 5% | 1.75 mm |

| Support material compatible with |

|---|

| Forward AM Ultrafuse® 17-4 PH, Forward AM Ultrafuse® 316L |

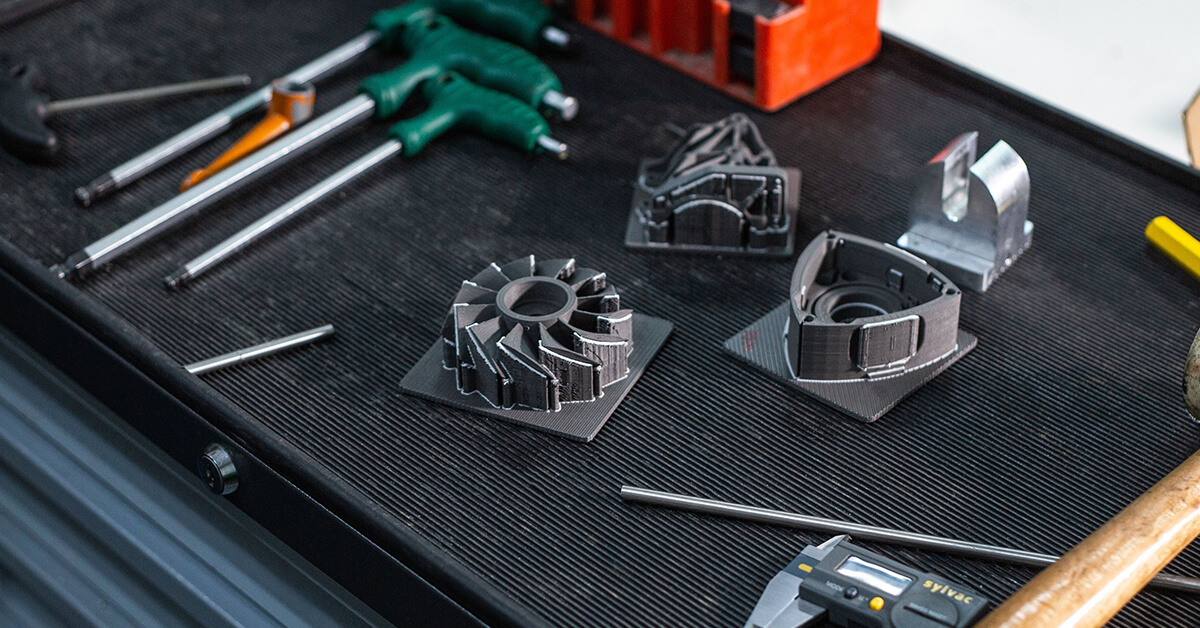

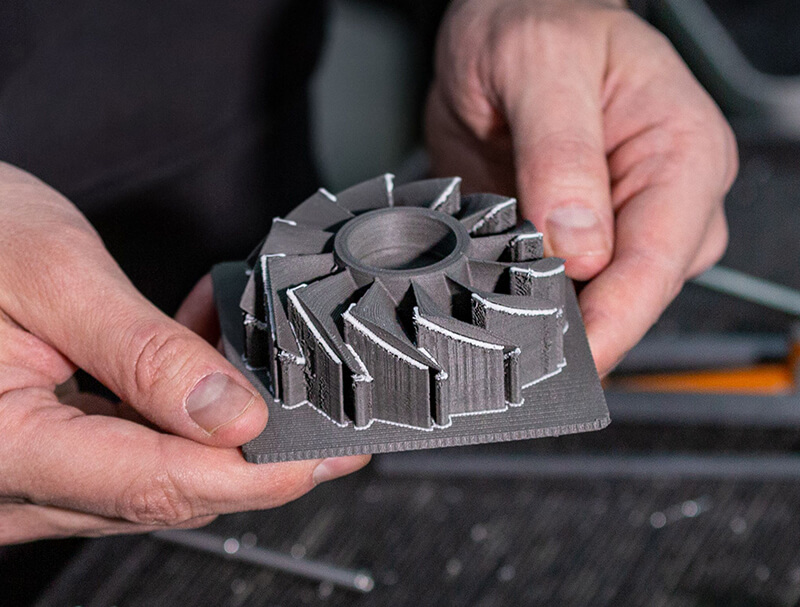

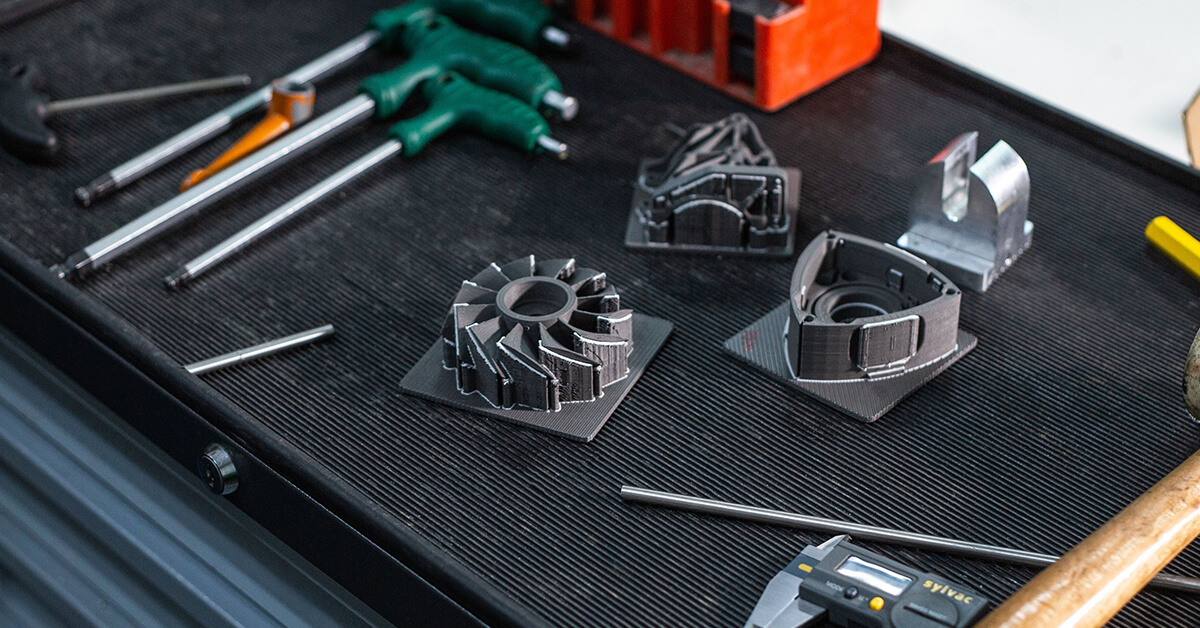

A steel turbine rotor before debinding and sintering process 3D printed on the Zortrax Endureal using Zortrax Full Metal Package 316L.

Forward AM Ultrafuse® 316L and Forward AM Ultrafuse® 17-4 PH

are two available metallic powder filaments corresponding to two types of steel. Here's how they are different.

| Type of steel | Corrosion Resistance | Structure | Mechanical performance |

|---|---|---|---|

| 316L | Stainless | Non-magnetic | Medium harndness / high elongation |

| 17-4 PH | Corrosive | Magnetic | High hardness / low elongation |

| Type of steel | 316L | 17-4 PH |

|---|---|---|

| Corrosion Resistance | Stainless | Corrosive |

| Structure | Non-magnetic | Magnetic |

| Mechanical performance | Medium harndness / high elongation | High hardness / low elongation |

Working with 17-4 PH steel 3D prints

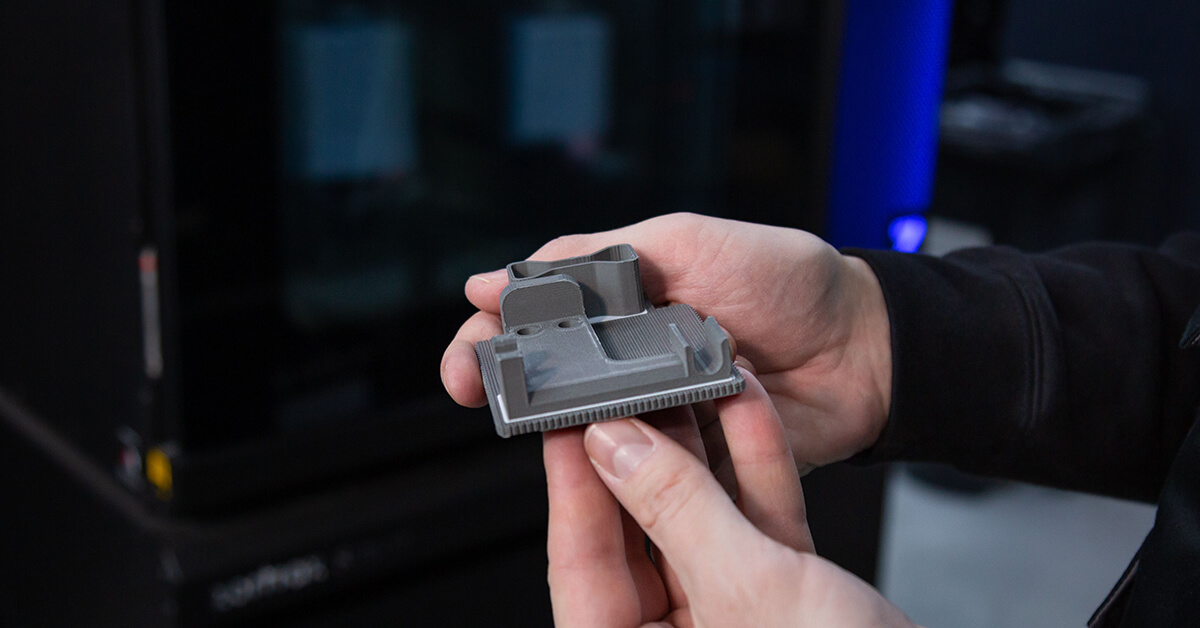

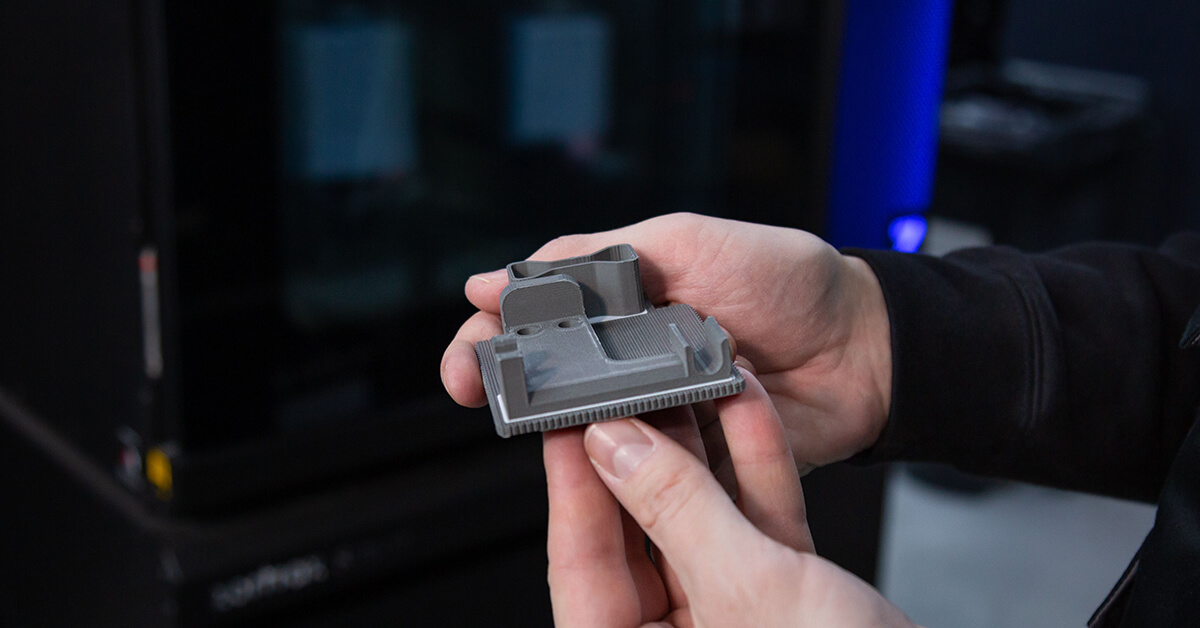

Metal parts 3D printed with Zortrax Full Metal Package 17-4 PH have high-quality surfaces even at the bottom which is important in manufacturing various types of brackets.

Components 3D printed with Zortrax Full Metal Package 17-4 PH can be easily welded and polished.

Low elongation and high yield strength make 17-4 PH steel great for positioning jigs.

17-4 PH steel is also perfect for rotors and turbine blades.