How 3D printing boosts packaging design

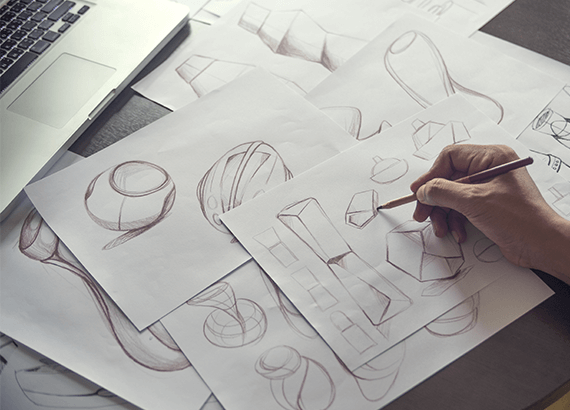

Concept arts of prototype packaging items that are to be 3D printed.

Packaging designers face three major challenges in their work

-

Packaging can be made with various materials, each requiring specific tools

-

A large number of prototypes is usually necessary

-

Ordering multiple one-off designs increases the overall cost of the prototyping stage

Complex

shapes

3D printers can print almost all shapes, so there is no significant price differences between different designs.

Wide range of materials

Filaments for 3D printers are designed to imitate various materials like wood, glass, or carbon fiber.

Multiple prototypes

Multiple design ideas can be evaluated simultaneously as one 3D printer can print multiple prototypes in one go.

In-house fabrication

Fabrication is done in-house to shorten lead times, lower the costs, and mitigate the risk of having the design leaked.

Workflow in using 3D printers for packaging design

Packaging designers can implement 3D printers in their work following four simple steps. Here's how it works.

Step 1: CAD design

A new packaging design is created in CAD software.

Step 2: Selection of target materials

Target materials are chosen to achieve the packaging looks and purpose.

Step 4: Fabrication and evaluation

The design is 3D printed with the chosen filaments and evaluated by stakeholders.

Step 3: Selection of filaments

3D printing filaments are chosen to closely match the target materials.

Step 1: CAD design

A new packaging design is created in CAD software.

Step 2: Selection of target materials

Target materials are chosen to achieve the packaging looks and purpose.

Step 3: Selection of filaments

3D printing filaments are chosen to closely match the target materials.

Step 4: Fabrication and evaluation

The design is 3D printed with the chosen filaments and evaluated by stakeholders.

3D printed packaging prototypes

3D printers can streamline prototyping processes in plastic packaging design. The technology is capable of fabricating models in almost all shapes while a wide range of filaments can be used to imitate a variety of target materials.

3D printing technologies for packaging design

The choice of the right 3D printing technology for packaging design depends on the projected size and complexity of prototypes.

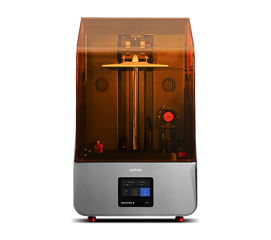

Small size prototypes with complex geometry

Resin 3D printing technologies like the Zortrax UV LCD are best for small yet intricately designed models.

See more

Medium size prototypes with simple geometry

LPD technology is the most cost-efficient for making simple medium size models.

See more

Medium size prototypes with complex geometry

LPD Plus technology is best for intricately designed, medium size details with complex internal architectures.

See more

Medium size prototypes with smooth surfaces

SVS automated post-processing devices can be used with LPD or LPD Plus printers to make packaging water-tight and aesthetically pleasing.

See more