Used by Professionals

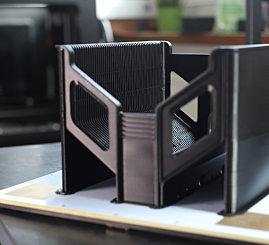

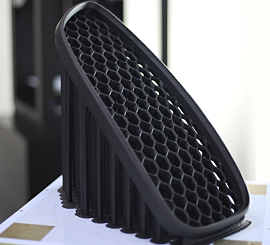

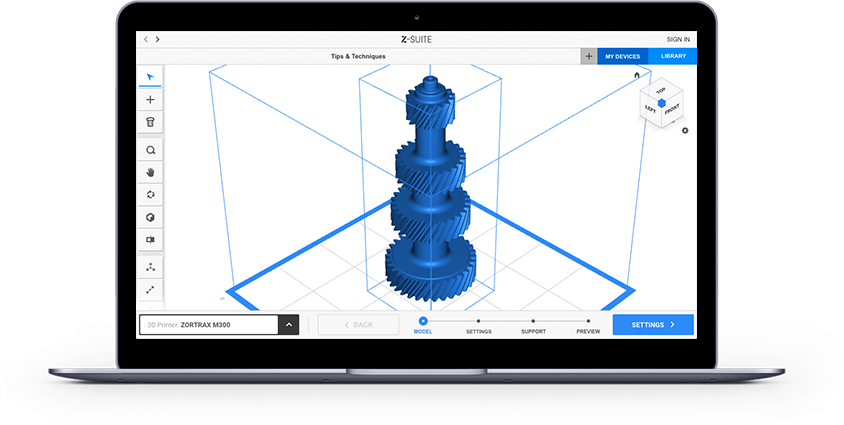

Zortrax M300’s reliability and large build volume has proven to be an indispensable prototyping and manufacturing tool for high-profile designers from various sectors of industry, including the development of functional aerospace tools by NASA Johnson Space Center engineers.