High-end 3D printer, resins and post-processing devices

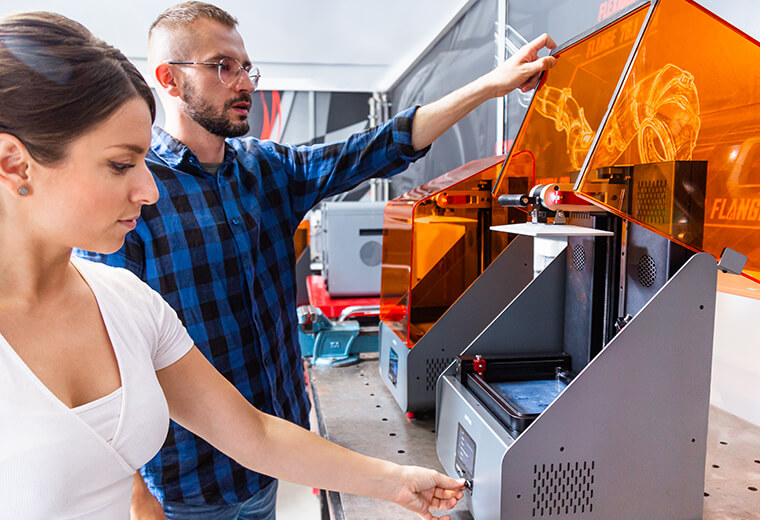

For a true success of your resin 3D prints, a reliable 3D printer is just as crucial as quality materials and post-processing devices. That is why the Inkspire 2 is compatible with best-performing resins from world-leading manufacturers like Forward AM and Henkel/Loctite. And once the printing is done, the parts can be post-processed using Zortrax Cleaning Station and Zortrax Curing Station: a professional post-processing ecosystem introduced along with the Inkspire 2.

Quality approved by top resin manufacturers

The Inkspire 2 is compatible with many advanced engineering resins, including those previously available only for DLP 3D printers. Zortrax is working with brands like Henkel/Loctite and Forward AM to ensure properties of parts printed with their best-performing resins match or exceed values specified by the manufacturer. This conformity is guaranteed by a thorough, two-stage validation process, where 3D printed models were first tested in-house by Zortrax and then, independently, by the resin manufacturers who made the test prints on pre-production Inkspire 2 units sent to their laboratories. Test samples were post-processed using Zortrax Cleaning Station and Zortrax Curing Station which means the validation extends to the entire Zortrax resin 3D printing ecosystem.

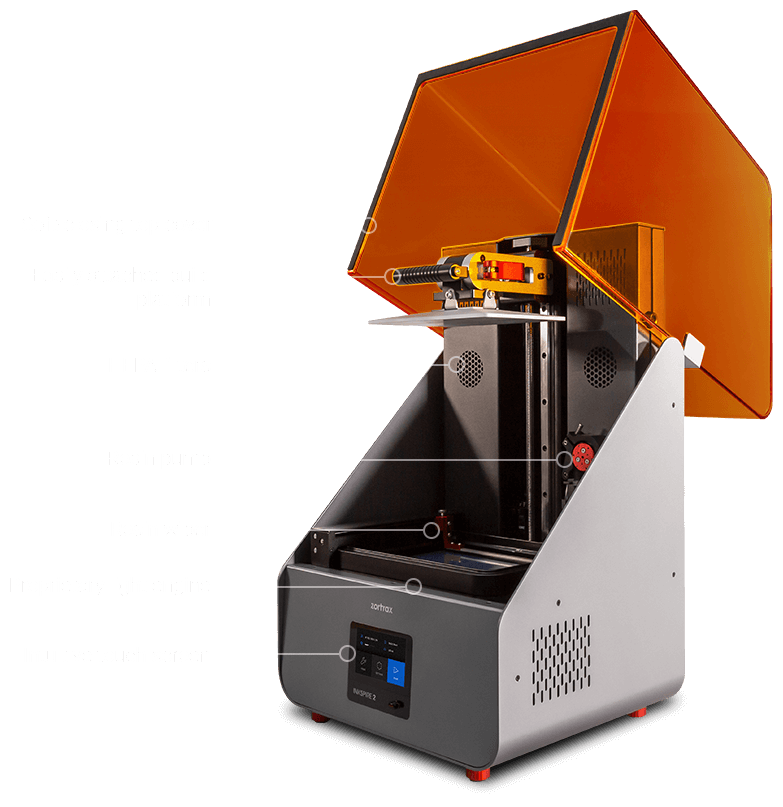

What makes the Inkspire 2 special

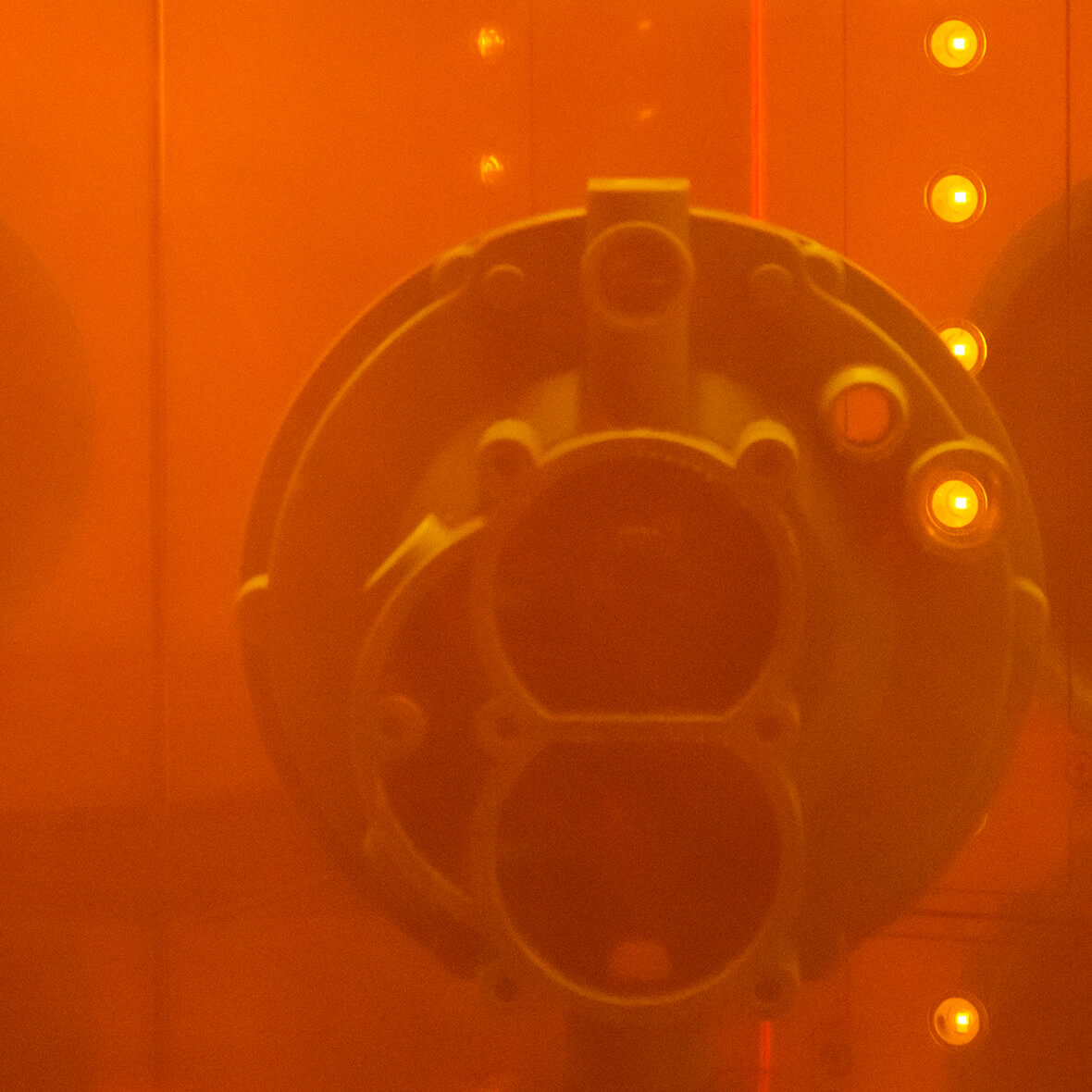

Industrial-grade proprietary light engine

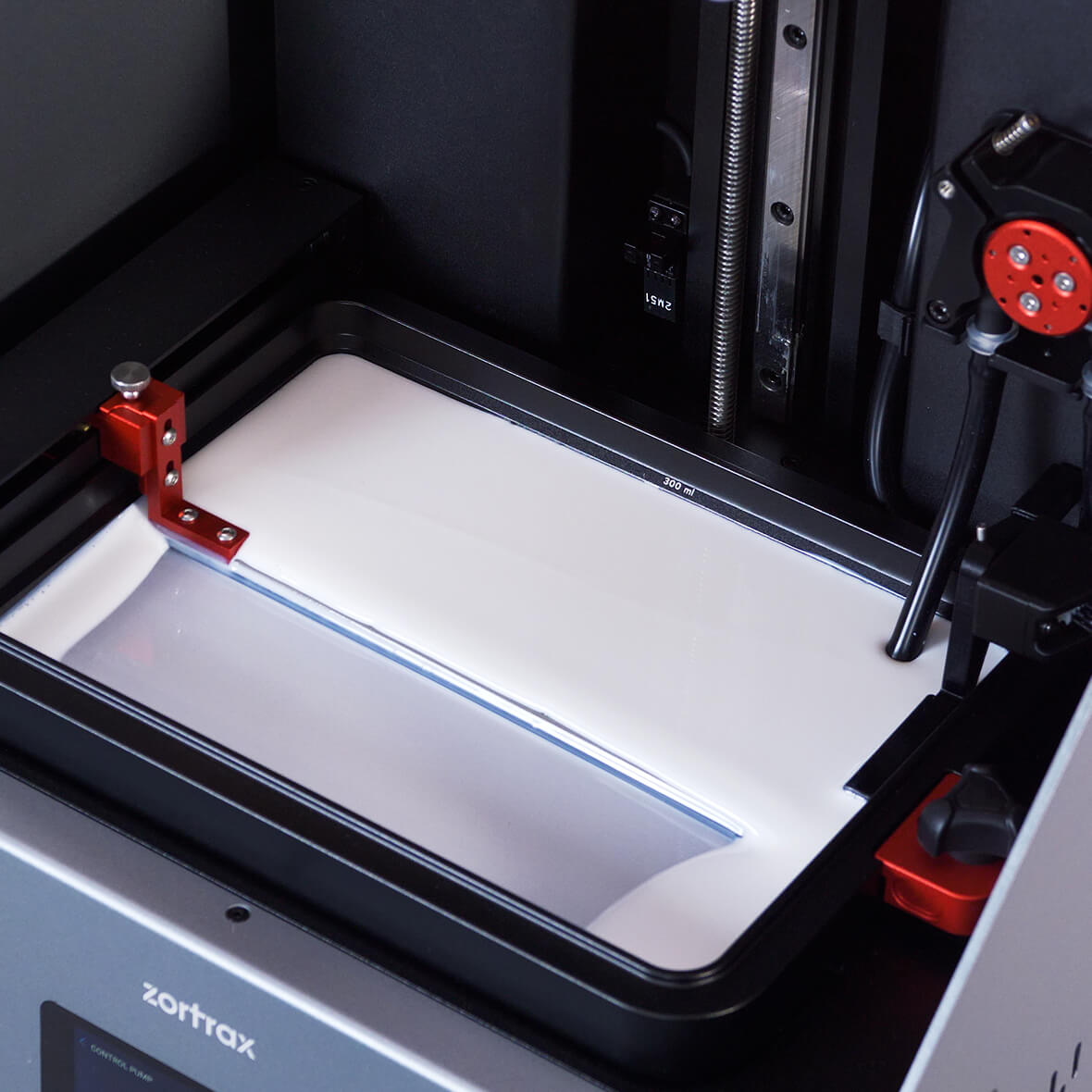

The light engine in the Inkspire 2 has been developed in-house from the ground up. Zortrax engineers designed an array of UV diodes backlighting a monochromatic screen to achieve uniform UV exposure of every single pixel on a large build platform while retaining utmost precision. Therefore, resin 3D models made on the Inkspire 2 have the same, outstanding quality, regardless of whether they are placed in the center or towards the edges of the build platform. Finally, this new light engine is seven times more powerful than a standard UV LCD screen, which makes Zortrax Inkspire 2 compatible with chosen DLP resins.

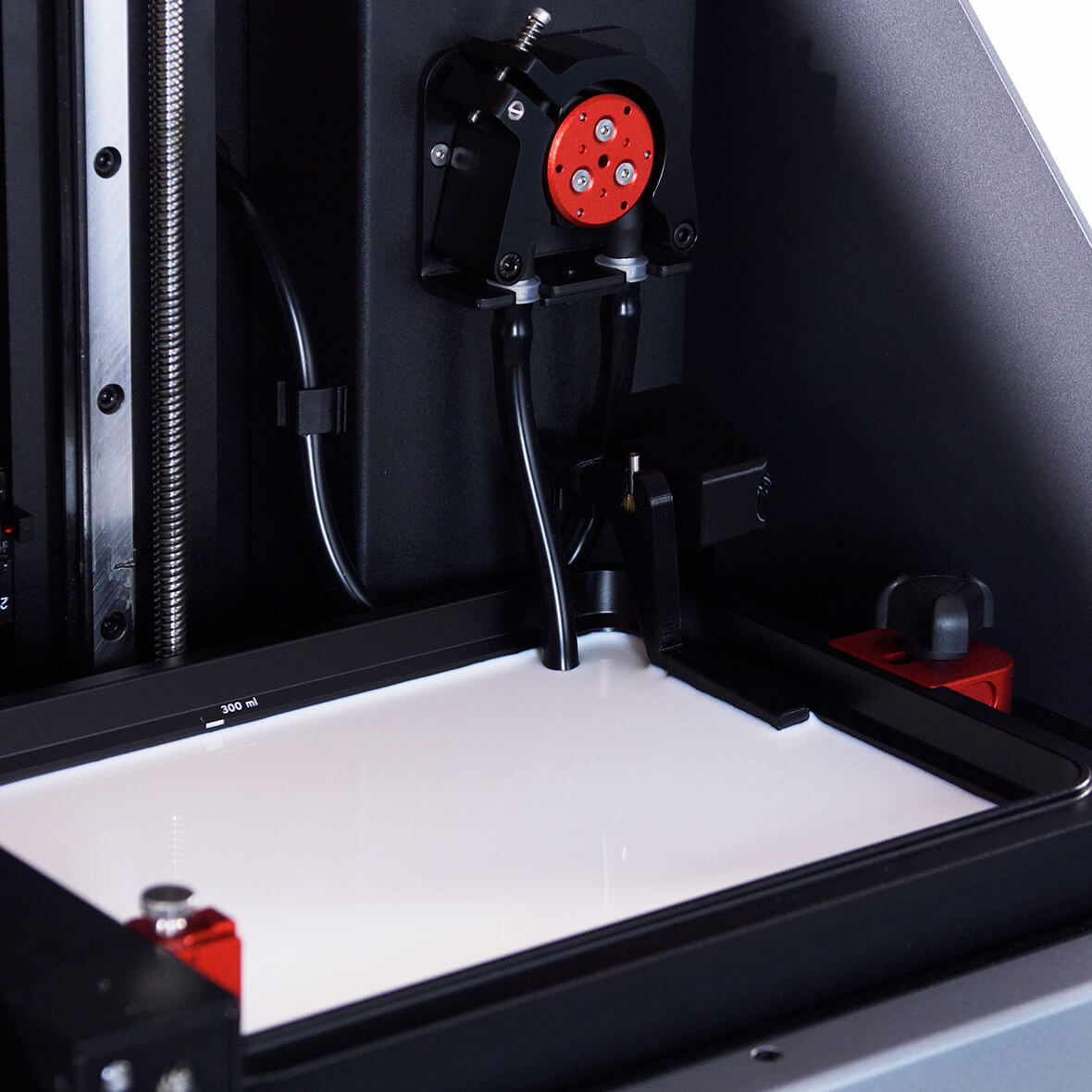

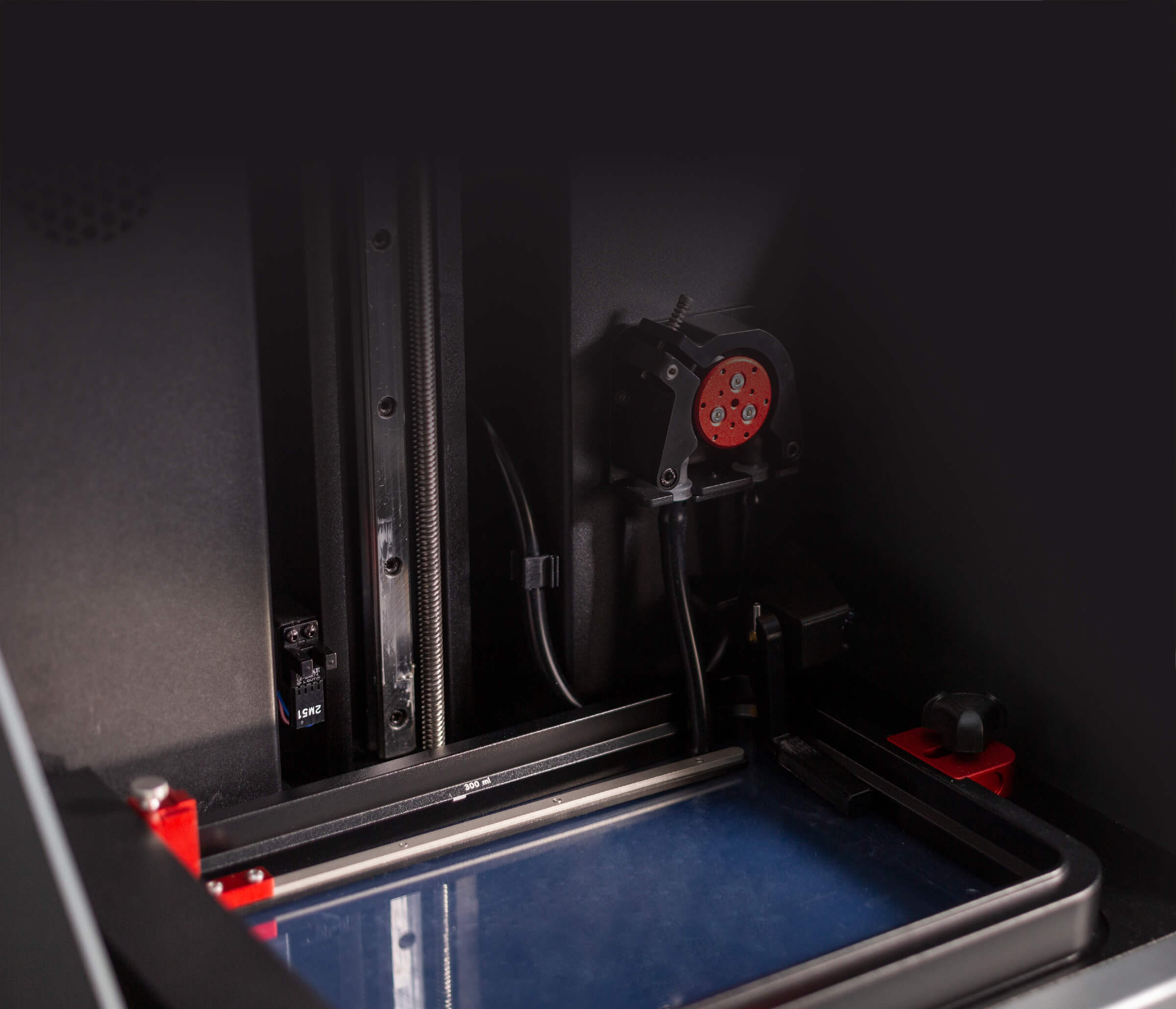

Clever automation

The Inkspire 2 makes the entire resin 3D printing process simple and clean through automation cleverly implemented in its key components. This makes working with photopolymer resins easier than ever.

Huge step forward

The Inkspire 2 3D printer builds upon the success of the original Inkspire and improves it in every possible way. The numbers tell the story of outstanding progress in Zortrax UV LCD printing solutions:

Made for world-class materials

The Inkspire 2 supports a wide range of high-end 3D printing resins supplied by world's most trusted manufacturers.

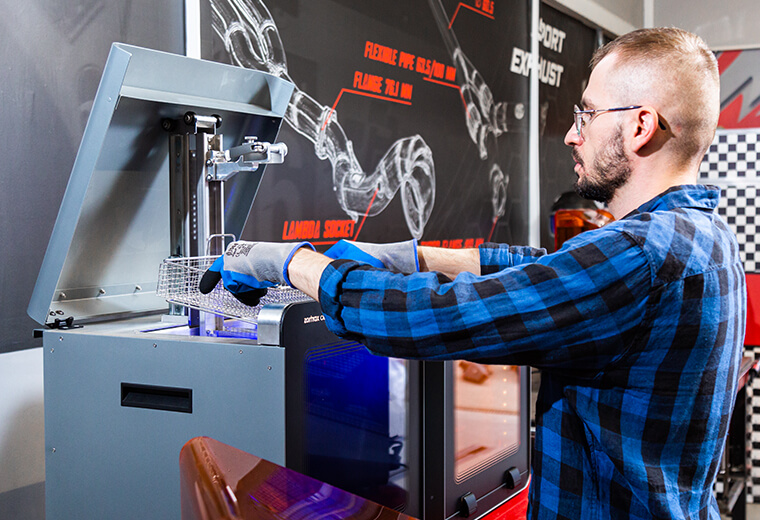

Advanced post-processing ecosystem

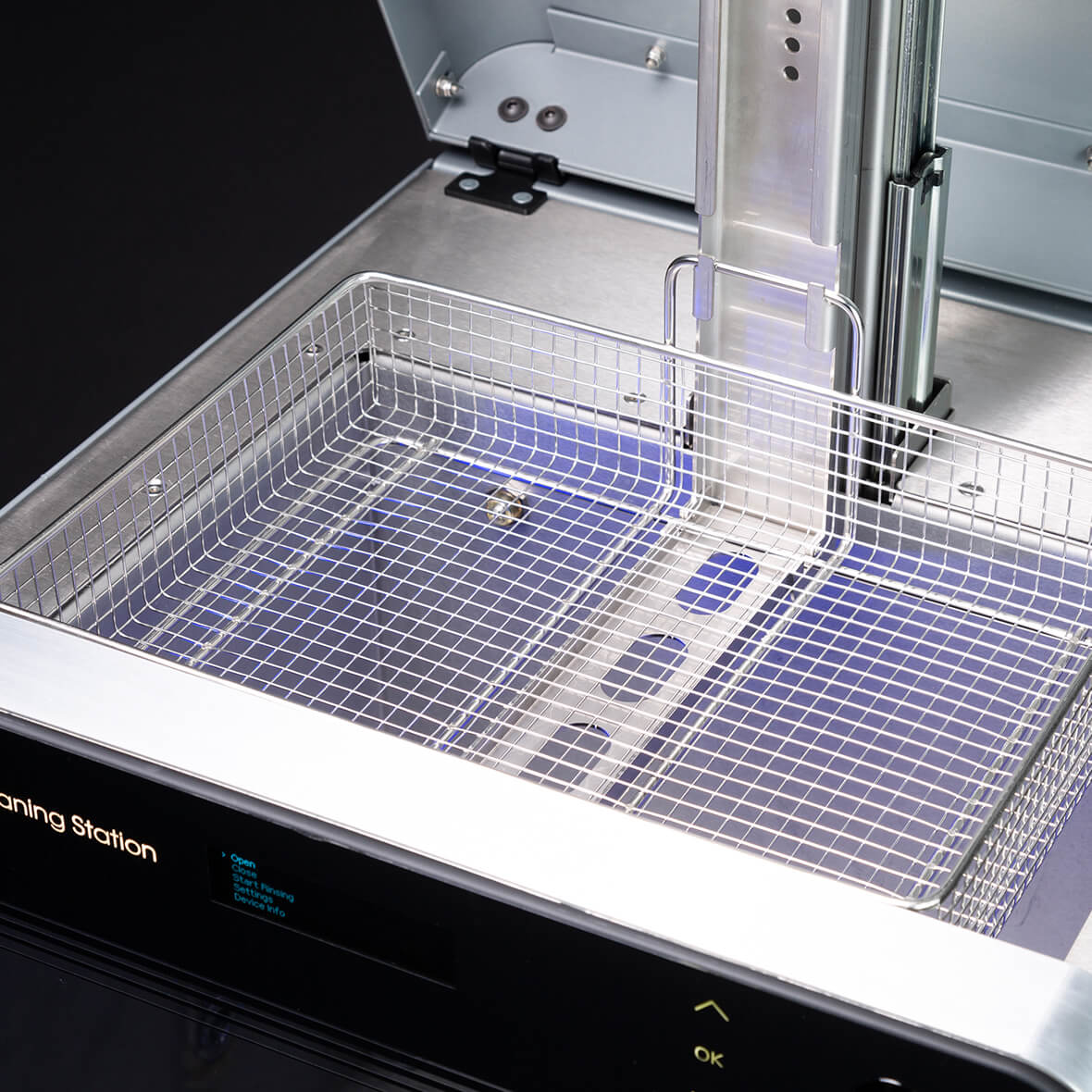

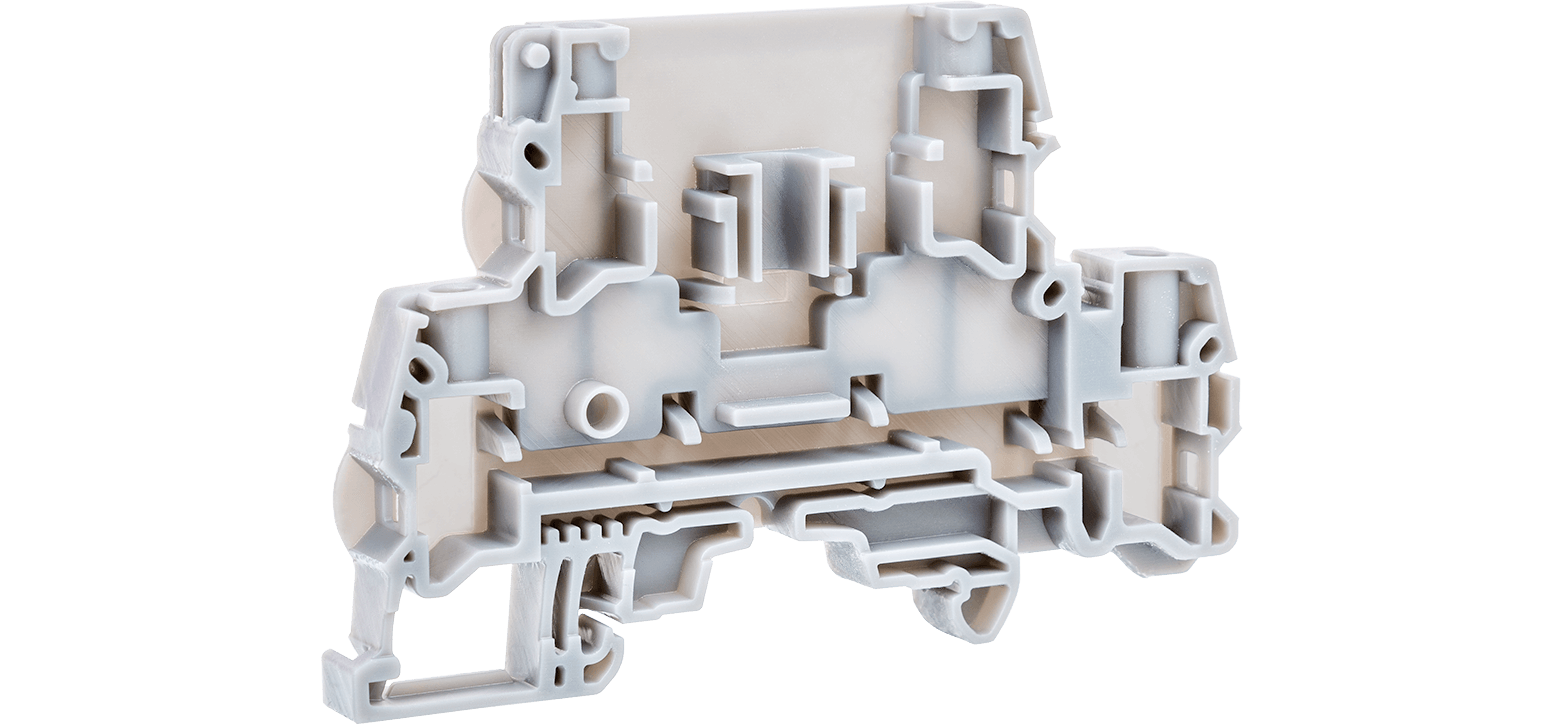

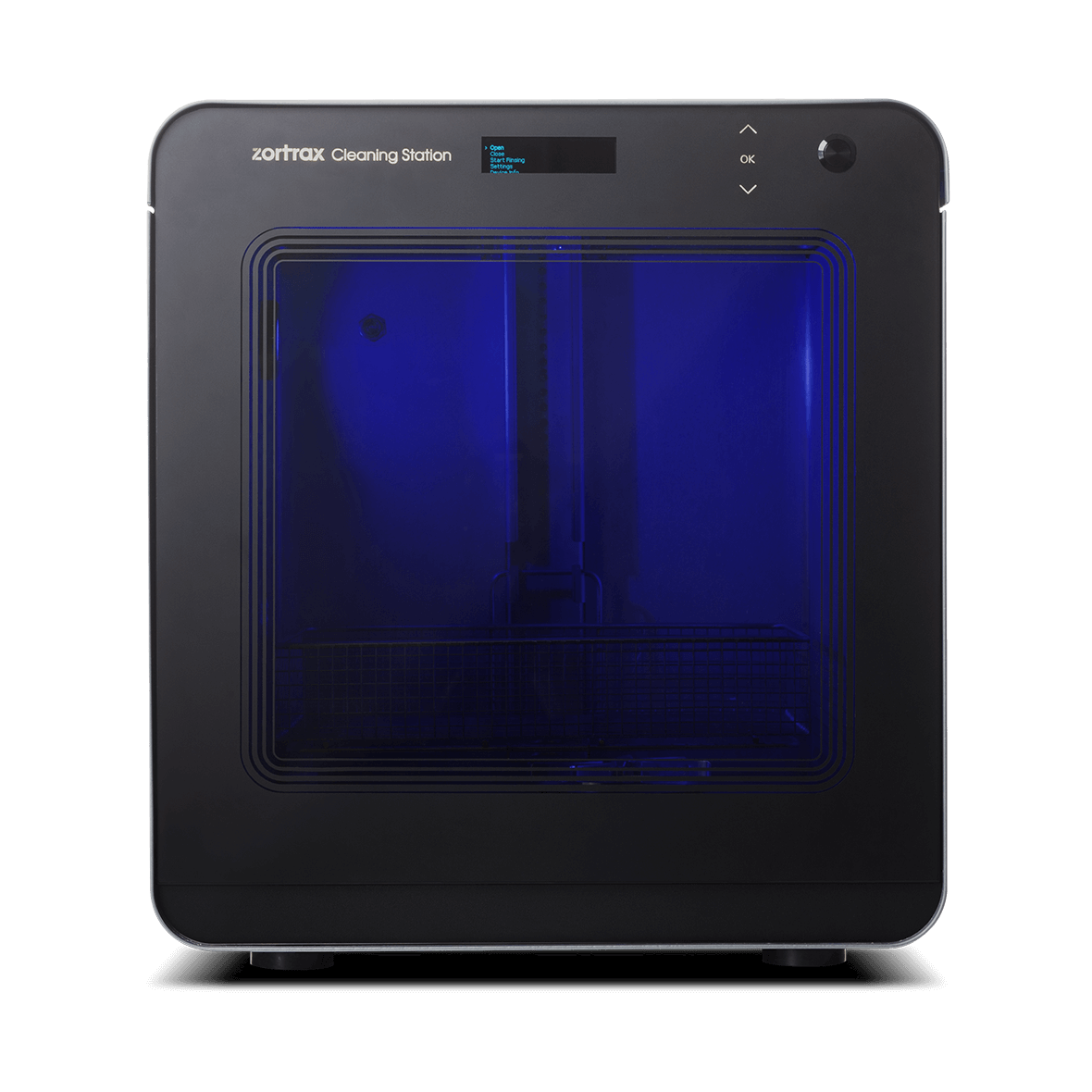

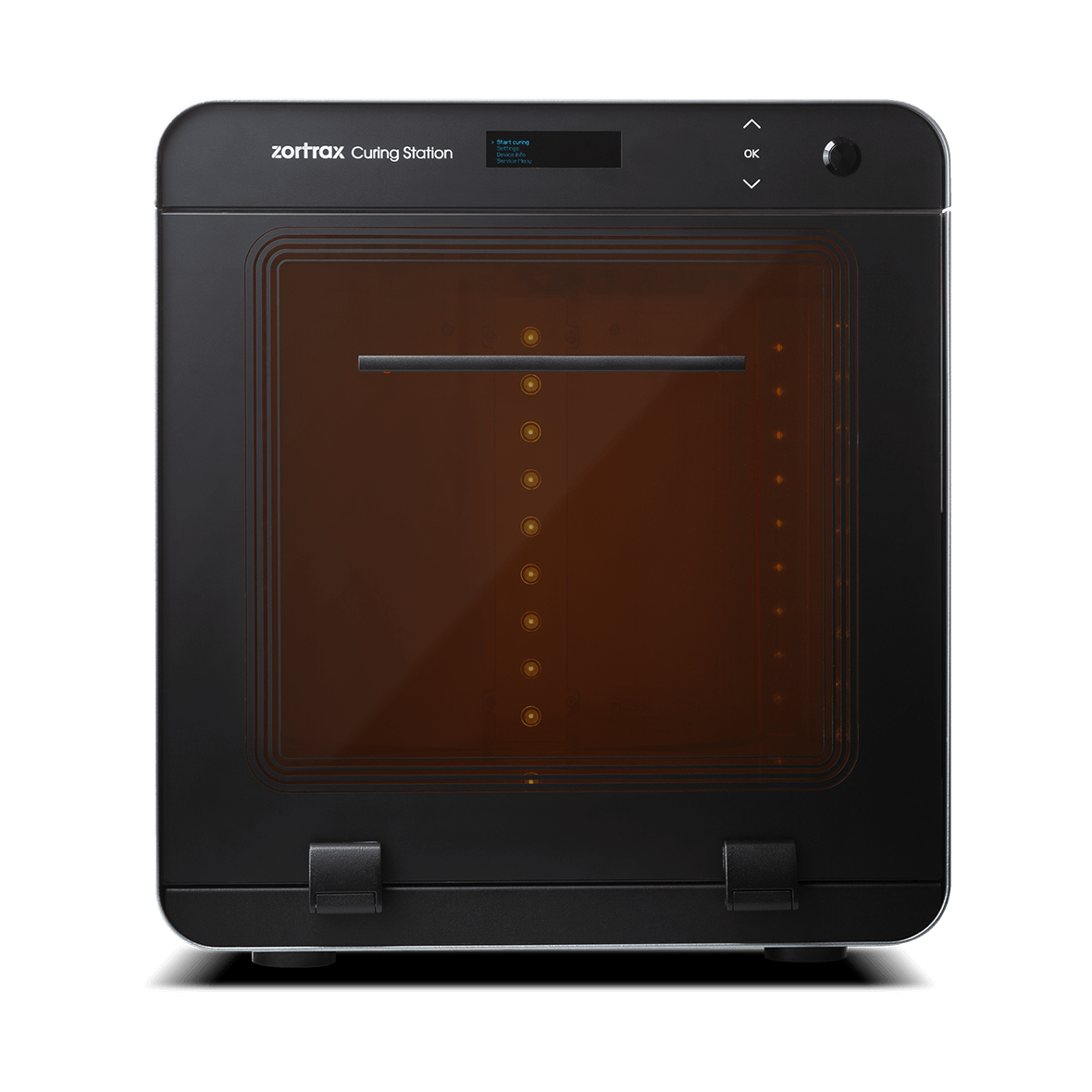

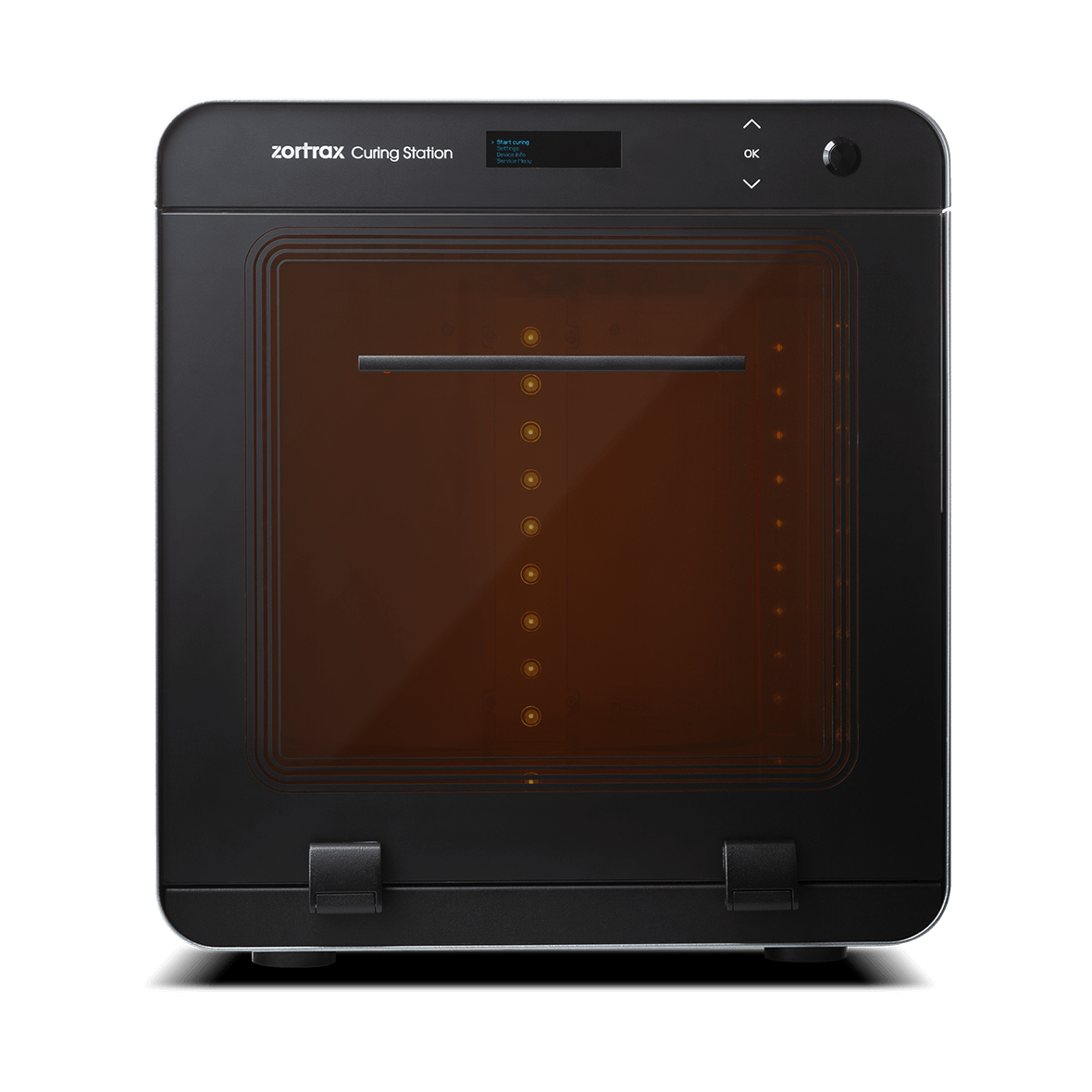

Most professional resins require post-processing to achieve manufacturer's declared properties after the printing is done. Therefore, Zortrax has introduced Zortrax Cleaning Station and Zortrax Curing Station: two automatic post-processing devices that complement the Inkspire 2 UV LCD 3D printer in an advanced ecosystem. The purpose of Zortrax Cleaning Station is to remove uncured resin from the surfaces of models while Zortrax Curing Station provides UV curing to materials that need it.

Software

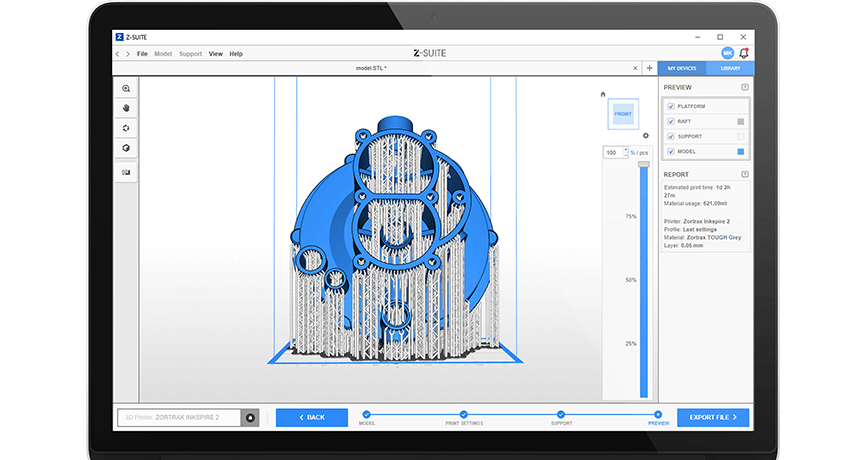

Z-SUITE is a slicing software that comes free with every Zortrax 3D printer. It is made to prepare digital models for 3D printing to achieve the best possible quality of printed parts in the shortest time.

Zortrax inCloud

The Inkspire 2 has Wi-Fi connectivity which makes it compatible with Zortrax inCloud, a cloud-based 3D printing management service.

Device

Software

Resins

Temperature

Electrical

Printing

In the box

Weight and physical dimensions

- around 80 kg (176.4 lb) - with cleaning fluid (full tank)

Device

- polypropylene cartridge (1 micron)

- stainless mesh cartridge with UV lighting (150 microns)

- flow meter preventing operation without the cleaning fluid in the system

Electrical

In the box

Physical dimensions

Device

- UV filter embedded into the front door

Electrical

In the box

Complement your 3D printer

Zortrax Cleaning Station

Learn More

Zortrax Curing Station

Learn More