Forward AM Ultrafuse® PPSU

Forward AM Ultrafuse® PPSU is an industrial high-performance 3D printing filament with flame retardancy properties. The filament complies with the EN 45545-2 railway classification as well as the UL 94 standard.

Forward AM Ultrafuse® PP GF30 is a polypropylene-based composite filament reinforced with a 30% addition of glass fiber. It is characterized by extremely high stiffness and resistance to heat, UV light, and chemicals. PP GF30 is lightweight and provides high dimensional accuracy to printed parts.

Forward AM Ultrafuse PAHT CF15 is an industrial-grade filament consisting of a polyamide base and a 15% addition of micro-carbon fibers. The filament shows high stiffness, high dimensional stability, and chemical resistance. It withstands the temperatures reaching up to 145 °C.

Z-PEEK is one of the strongest polymers on the planet. It has strength-to-weight ratio comparable to stainless steel and exceptional thermal properties, and can be used in space industry even for out of cabin applications. The material can withstand thermal-cycling in vacuum chambers used for space-qualification tests.

Z-PEI 1010 is a blend of PEI which is slightly stronger than Z-PEI 9085 and with higher heat deflection temperature. The material can withstand temperatures reaching 208 °C. It offers broad chemical resistance to automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions.

Z-PEI 9085 is a durable, aerospace-grade polymer with strength-to-weight ratio comparable to aluminum 6061. This filament consists of polyetherimide with a polycarbonate copolymer blend. Z-PEI 9085 exhibits excellent thermal properties and retain its properties in temperatures reaching 167 °C.

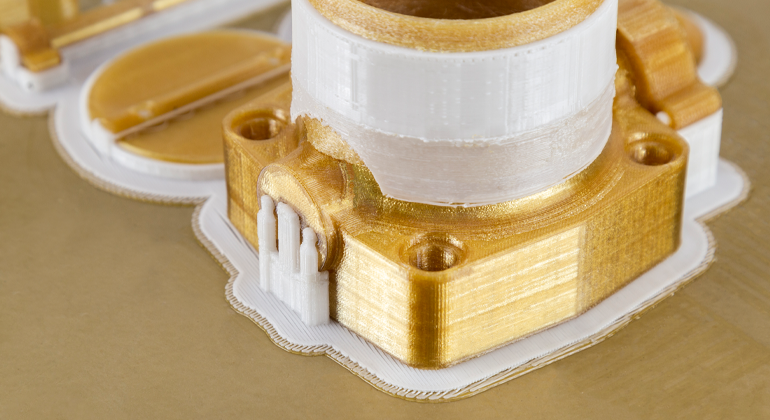

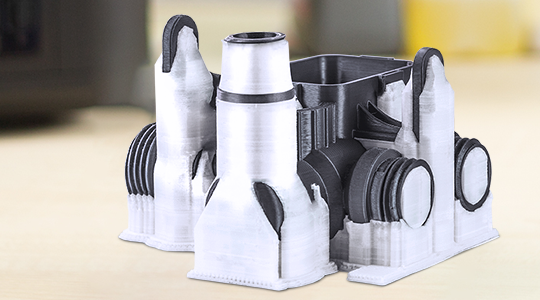

Z-SUPPORT Premium is a water-soluble support filament made of butenediol vinyl alcohol co-polymer (BVOH). It's compatible with Z-GLASS, Z-PETG, Z-PLA, Z-PLA Pro, Z-ULTRAT and Z-ULTRAT Plus as it can work in a relatively wide range of printing temperatures. Z-SUPPORT Premium has a very fast dissolution rate and leaves no remnants on the model.

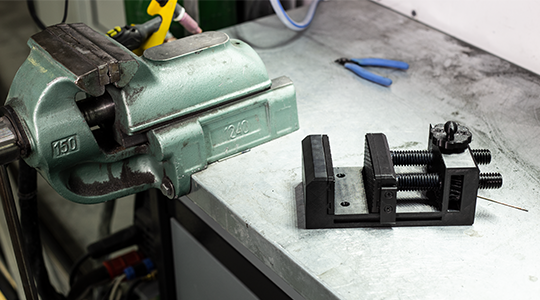

Z-NYLON is a versatile and strong 3D printing filament resistant to high temperatures and various chemicals. It can be post-processed with tools meant for machining metals. Z-NYLON is hard to break and easy to paint as it can be colored with commonly used, acid-based clothing dyes.

Z-FLEX is a thermoplastic polyester elastomer that can be 3D printed at a relatively fast rate of 45mm/s. The filament has great interlayer adhesion and dimensional tolerance falling below +/- 0,02 mm. Z-FLEX is elastic, can bend without breaking, and is resistant to various chemicals including gasoline, ethyl alcohol, butane, and carbon monoxide.

Z-PLA Pro is a biodegradable 3D printing material with an addition of chalk offering even and matt gypsum-like surface that makes the details more visible. Reduced shrinkage allows to 3D print large models with almost no warping.

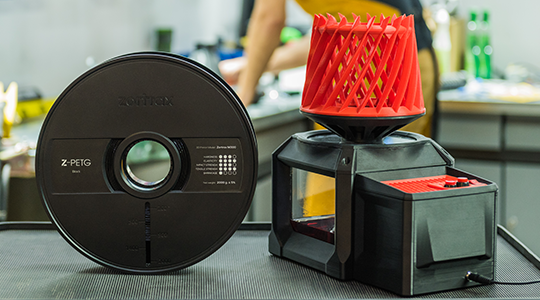

Z-PETG is made of popular PET thermoplasticics enhanced with addition of Glycol to eliminate the brittleness. This industrial-grade material can withstand both UV rays and time. It also exhibits high resistance to oils and greasy substances.

Z-PCABS is a durable blend of Polycarbonate and ABS characterized by impact, UV light and temperature resistance. This strong 3D printing filament can also withstand exposure to salts, acids and alkalis and doesn’t change its properties over the course of time.

Z-PLA filament is perfect for precise 3D printing of structurally complex objects, like architectural mock-ups and conceptual models. This biodegradable 3D printing material is derived from environment-friendly sources. Z-PLA offers your models with high-quality details and exceptionally smooth surface.

Z-ULTRAT is an exceptionally durable and time-lasting filament. Available in a wide range of colors, Z-ULTRAT is well-suited for all kinds of high-quality applications: functional prototyping, casings, end-use parts, tools and art. The 3D printing material’s surface can be easily post-processed with acetone and mechanical treatment.

Z-HIPS 3D printing material is best used for parts and models requiring smooth surface which can be effortlessly post-processed. Its hardness makes it perfect for mechanical prototyping and performance testing. Quality of models 3D printed with Z-HIPS is close to mass-produced objects.

With Z-GLASS transparent filament you can 3D print light-transmitting models and parts ready for final production or precise prototyping. The material is durable, resistant to scratching and remains unaffected by light and chemicals. Z-GLASS is resistant to shrinking.

Z-ESD filament grants your models electrostatic discharge protection, making it a reliable choice for electronic industry. Reduced shrinkage and warping allow you to 3D print precise end-use parts and tools. Moreover, Z-ESD material is protected against harmful effects of salts, acids and alkalis.

Z-ASA Pro 3D printing filament is designed to withstand adverse environments. The material is highly resistant to the changing weather conditions and UV light, which makes it ideal for outdoor applications, like specialized tools or prototypes tested outside. Low shrinkage and warping of Z-ASA Pro allow you to accurately 3D print large models.

Z-ABS 3D printing material is a universal solution for economical prototyping and manufacturing. Matt surface of this basic plastic filament enables easy post-processing, both mechanical and chemical. Z-ABS is an excellent choice for beginning users, as well as professional looking for low-cost drafting and testing.