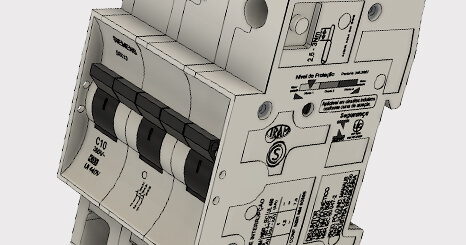

Step 1 CAD/CAM design

Each device begins its life in a CAD/CAM design software. There are different programs for designing printed circuit boards (PCBs), electrical engineering, and for modeling the casings.

Additive manufacturing is changing the way professional electronic devices are developed. Flexibility, speed, and precision of modern resin 3D printers have to offer significantly shorten the time to market (TTM) of products intended for mass production and lower the cost of custom-made equipment.

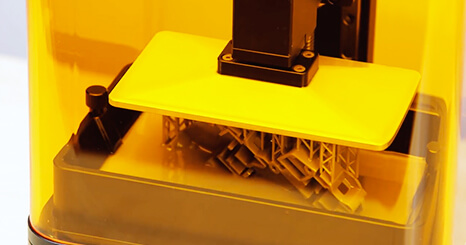

Professional electronics are made to constantly work in challenging environments over long periods of time. Resin 3D printers are precise and fast enough to rapidly apply even minuscule changes in the design necessary to make them fail-safe. Because the development process is usually long and thorough, a reliable resin 3D printer saves a lot of time and money in comparison with injection molding.

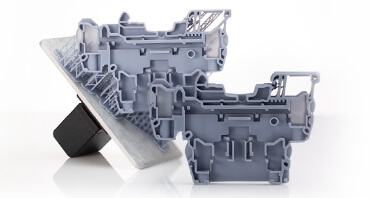

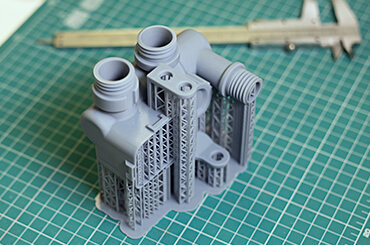

Resin 3D printers can be used to make functional prototypes similar to final products, parts for custom-made devices,

and for manufacturing the first short series of the final product.

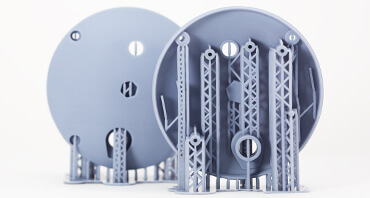

The RCDs are devices that instantly break electric circuits to prevent serious harm from electric shock or damaging the equipment. With a resin 3D printer it is possible to tailor the RCD's design to a particular circuit.

Charging stations for electric vehicles support various different socket types. Resin 3D printers allow to easily make EV charging connectors compatible with a chosen standard.

Replacement parts for custom-made equipment are usually very expensive. With a resin 3D printer it is possible to print them in-house which saves money and shortens lead times.

From CAD/CAM design, through building the first conceptual model and rapid prototyping, to early stages of manufacturing, resin 3D printers have become widely used in professional electronics design. Here's how a typical product development process looks like with resin 3D printers onboard.

Each device begins its life in a CAD/CAM design software. There are different programs for designing printed circuit boards (PCBs), electrical engineering, and for modeling the casings.

Once the particular PCBs and wiring layout is chosen, an appropriate casings and other parts designed to hold them in place can be 3D printed to build the first conceptual model and all its further versions.

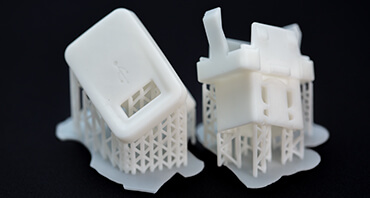

3D printers used at the prototyping stage can produce the first short series of the new product meant either for beta-testing or for generating income which is then reinvested in scaling up to mass production.

Zortrax Inkspire is a resin UV LCD 3D printer with significant precision and speed. It works with 50x50 microns XY resolution and 25 microns minimal layer height which is enough to print small casings and other elements necessary for modern electronics. Because its LCD screen with UV LED backlighting cures each model's layer all at once, Zortrax Inkspire has up to 8x speed advantage over leading SLA 3D printers. That's why it can be easily scaled up to work in a 3D printing farm offering medium to large manufacturing output.

Four most important questions to ask when choosing a resin 3D printer for engineering in electronics are how precise it is, how fast it is, how well does it scale up, and how effective it is in supporting early stages of manufacturing. Zortrax Inkspire is better than a leading SLA 3D printer in all those areas.

Bridge manufacturing is meant to mitigate the risks that come with moving on from the prototyping stage to mass production. The initial series of the new product can be manufactured on a farm of Zortrax Inkspire 3D printers. Large businesses tend to use this technique to build a number of products which are then used in beta testing or sent to stakeholders or influencers. Smaller businesses rely on bridge manufacturing to generate income needed for scaling up.

Z-SUITE is a dedicated slicing and 3D printing farm management software that comes free with every Zortrax 3D printer. It is compatible with the most popular CAD/CAM software solution. Zortrax Inskpire can also work with third-party slicers.

Zortrax Inkspire works with a range of dedicated resins. Third-party photopolymers are fully supported, provided they can be cured by light with a 405 nm wavelength.

Zortrax Resin PRO

Zortrax Resin PRO is an epoxy-based resin with improved impact and bending resistance in comparison with Zortrax Resin Basic. It offers short curing times, high degree of detail, and ease of post-processing.

Zortrax Resin FLEXIBLE

Zortrax Resin FLEXIBLE is an elastic, epoxy based resin that comes back to its original shape after bending. It offers smooth surfaces, high level of detail, and sharp edges.

Zortrax Resin BASIC

Zortrax Resin BASIC is an epoxy-based resin dedicated for Zortrax Inkspire. It guarantees impeccable details and great mechanical properties. It's also durable, easy to paint and needs short curing times.