How 3D printing supports traditional production lines

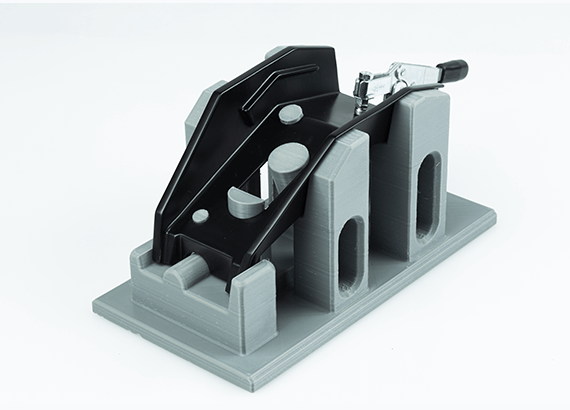

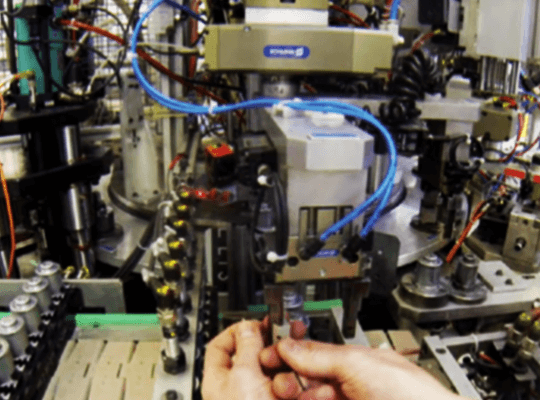

A customized jig 3D printed in-house at a manufacturing plant.

Production managers face three major challenges in keeping their operation costs low

-

Production line support consumables are relatively expensive

-

Large quantities of such consumables have to be kept on stock

-

Customized jigs and fixtures take a lot of time to fabricate

Cutting costs

3D printers can print consumables like rubber robotic arm grippers at a fraction of their market price.

In-house fabrication

Jigs, fixtures, and other consumables can be 3D printed on the spot when they are needed.

Customized parts

It's possible to 3D print one-off parts designed for specific applications at specific production plants.

Reducing storage

Production line consumables can be 3D printed on an on-demand basis and don't need to be held on stock.

Workflow in supporting production lines with 3D printers

3D printers can be implemented to support production lines in four simple steps. Here's how it works.

Step 1: Problem identification

Engineering personnel identifies the parts that would improve efficiency in their areas of responsibility.

Step 2: CAD design

Appropriate parts are designed in CAD software to meet the requirements specified by the engineers.

Step 4: Implementation

Jigs, fixtures, and other production line consumables are implemented in the manufacturing processes.

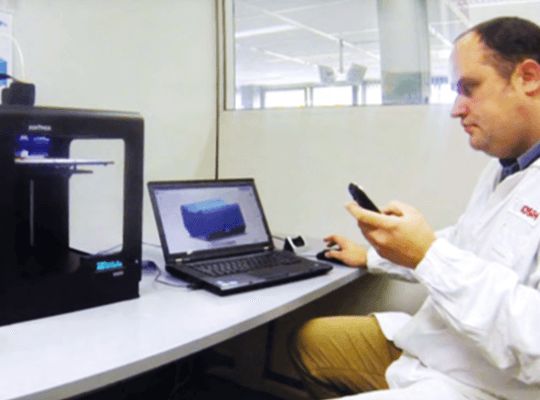

Step 3: 3D printing

3D printed models are fabricated on the spot based on the CAD designs.

Step 1: Problem identification

Engineering personnel identifies the parts that would improve efficiency in their areas of responsibility.

Step 2: CAD design

Appropriate parts are designed in CAD software to meet the requirements specified by the engineers.

Step 3: 3D printing

3D printed models are fabricated on the spot based on the CAD designs.

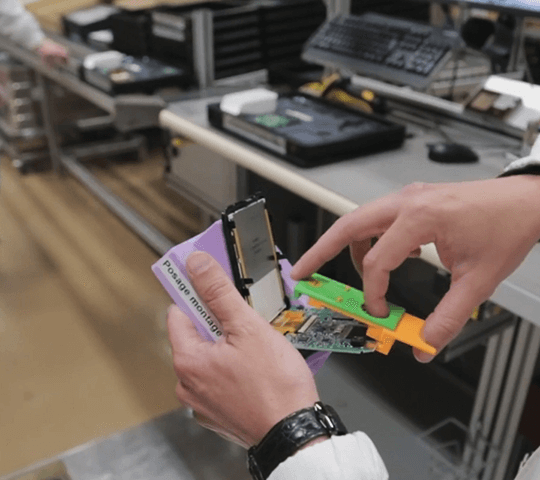

Step 4: Implementation

Jigs, fixtures, and other production line consumables are implemented in the manufacturing processes.

How Bosch works with 3D printers

Bosch has implemented 3D printers at their production plant located in Mondeville, France. By in-house, on-demand fabrication of various jigs and fixtures, the plant saved over €80,000 in year one.

3D printed jigs and fixtures

Working with Bosch engineers resulted in development of the unique Z-ESD material designed to print casings providing electrostatic discharge protection for electronics on the production floor. Other items 3D printed at the factory included customized consumables like grippers for robotic arms.

Technologies for production line support

The choice of the right 3D printing technology for production line support depends on the size and purpose of the parts.

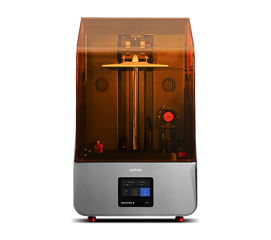

Small size parts with complex geometry

Resin 3D printing technologies like the Zortrax UV LCD are best for small yet intricately designed parts meant for equipment used in manufacturing of electronics e.g.

See more

Medium size models with simple geometry

LPD technology is the most cost-efficient for making simple medium size parts that can be used with the equipment for manufacturing car parts or consumer goods.

See more

Medium size models with complex geometry

LPD Plus technology is best for intricately designed, medium size parts with complex internal architectures like housings for manufacturing tools.

See more

Medium size products with smooth surfaces

SVS automated post-processing devices can be used with LPD or LPD Plus printers to make parts with smooth surfaces reducing friction.

See more