Why flexible manufacturing is good for business

A short series of computer fan covers that has been made on a 3D printer.

Flexible manufacturing is an answer to three major challenges businesses face in production of customized goods

-

Traditional manufacturing techniques are cost-efficient only in mass production of uniformly designed items

-

One-off products made on order are price-prohibitive for the vast majority of potential customers

-

Highly customized products take a lot of time to make, so delayed delivery diminishes customer experience

Customer participation

Customers can participate in the early design stage to ensure the final product will meet their requirements which is important in both B2C and B2B scenarios.

Short lead times

3D printers can fabricate all kinds of products without retooling, so the production can start immediately after the design has been agreed upon.

Mass customization

Each machine in a large cluster of 3D printers can work on an entirely different product, so customized goods can be offered to mass audience.

No costs of storage

Flexible manufacturing can work on the on-demand basis, so there is no need to bear the costs of holding an excessive inventory.

Workflow in flexible manufacturing

Flexible manufacturing is done in four simple steps. Here's how it works.

Step 1: Inclusive design

A new product is designed based on customer's input.

Step 2: Division of work

3D printers are dynamically assigned to incoming orders.

Step 4: Assembly

Functional products are assembled from the 3D printed parts.

Step 3: Post-processing

3D printed parts are post-processed if necessary.

Step 1: Inclusive design

A new product is designed based on customer's input.

Step 2: Division of work

3D printers are dynamically assigned to incoming orders.

Step 3: Post-processing

3D printed parts are post-processed if necessary.

Step 4: Assembly

Functional products are assembled from the 3D printed parts.

Technologies for bridge manufacturing

The choice of the right 3D printing technology for flexible manufacturing depends on the kind and size of products.

Small size products with complex geometry

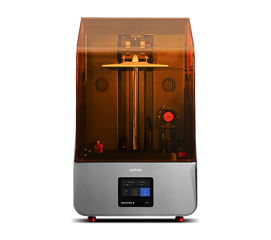

Resin 3D printing technologies like the Zortrax UV LCD are best for manufacturing large quantities of small yet complex products.

See more

Medium size products with simple geometry

LPD technology is the most cost-efficient for manufacturing simple medium size products like lighting appliances or packaging.

See more

Medium size products with complex geometry

LPD Plus technology is best for intricately designed, medium size parts like movable mechanism or organic shapes.

See more

Aesthetically pleasing medium size products

SVS automated post-processing devices can be used with LPD or LPD Plus printers to manufacture products with superior aesthetics.

See moreOur Users stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.