Krok 1 Wydrukuj

Wydrukuj model na dowolnej drukarce 3D typu FDM, FFF lub LPD/LPD Plus.

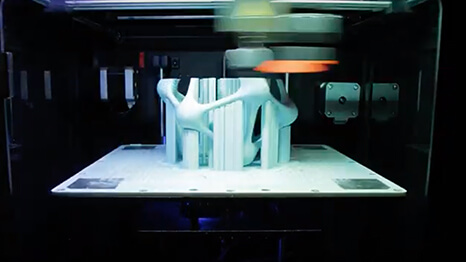

Zortrax Apoller to desktopowe urządzenie do inteligentnego wygładzania powierzchni modeli 3D oparami, gwarantujące przemysłową jakość pracy. Każdy etap wygładzania jest zarządzany przez dedykowane algorytmy, dzięki czemu wydruki 3D wykonane w technologii FDM wyglądają jak detale tworzone techniką formowania wtryskowego.

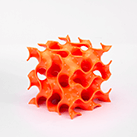

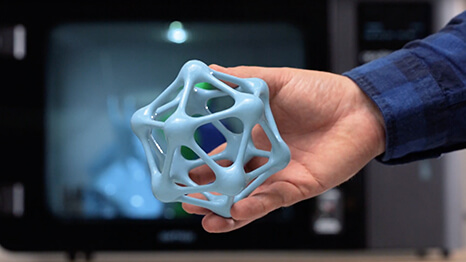

Technologia SVS (Smart Vapor Smoothing) wygładza w równomierny sposób nawet najmniejszy detal, jak również wydruki z ruchomymi elementami czy te o skomplikowanej geometrii. Odbywa się to poprzez automatyczne zarządzanie temperaturą, ciśnieniem oraz gęstością oparów rozpuszczalnika w komorze roboczej Apollera.

Zortrax Apoller może wygładzać modele wydrukowane na wszystkich drukarkach 3D drukujących w technologiach FDM, FFF, LPD i LPD Plus. Urządzenie jest kompatybilne z filamentami opartymi o ABS, HIPS i ASA, niezależnie od ich producenta. W roli rozpuszczalnika należy natomiast stosować wyłącznie czysty aceton lub czysty MEK.

Farmy drukarek 3D są bardzo oszczędnymi rozwiązaniami i doskonale radzą sobie z produkcją niskoseryjną, umożliwiając wprowadzanie szybkich zmian w projektach. Wyposażone dodatkowo w urządzenia do post-processingu Apoller są zdolne tworzyć produkty o jakości równej tym wykonanym za pomocą formowania wtryskowego.

Przy współpracy z zewnętrznymi dostawcami praktycznie nie ma miejsca nie ma miejsca na dowolność we wprowadzaniu zmian w projekcie, a w przypadku produkcji niskoseryjnej dodatkowo pojawia się problem wysokiego kosztu jednostkowego produktu. Obniżenie kosztów będzie możliwe dopiero przy odpowiedniej skali. Po zainwestowaniu w produkcję form wtryskowych, firma praktycznie nie ma już odwrotu od podjętych wcześniej decyzji projektowych.

Cały proces wygładzania modeli 3D jest prosty, zautomatyzowany i bezpieczny, dzięki czemu może być przeprowadzony przez nieprzeszkolony personel.

Wydrukuj model na dowolnej drukarce 3D typu FDM, FFF lub LPD/LPD Plus.

Wstaw model do komory wygładzającej, zamknij drzwi i wybierz właściwe ustawienia na ekranie dotykowym.

Apoller zajmie się całą resztą. Po ok. 3 godzinach modele są wygładzone i gotowe do użycia.

System próżniowy w Zortrax Apoller zapobiega wzrostowi ciśnienia wewnątrz komory roboczej względem ciśnienia na zewnątrz nawet wówczas, gdy rozpuszczalnik został odparowany. Dzięki temu komora jest szczelna i rozpuszczalniki nie wydostają się na zewnątrz.

Opary znajdujące się wewnątrz komory roboczej Zortrax Apoller są rozprowadzane ku górze aby równomiernie pokryć model. Równocześnie delikatne i skomplikowane geometrycznie detale są pokrywane mniejszą ilością rozpuszczalnika, aby pozostawić ich kształt nietknięty. Po zakończeniu procesu, system kondensacji zbiera nadmiar rozpuszczalnika, który można ponownie wykorzystać.