The Summary of 2022 at Zortrax

2022 has been fruitful at Zortrax, bringing further development of our brand and our portfolio. We’ve launched several new, groundbreaking products, including a vastly media-covered Zortrax Powerful Trio – a refined resin ecosystem, which comprises Zortrax Inkspire 2 UV LCD 3D printer, as well as two automatic post-processing devices, Zortrax Cleaning Station, and Zortrax Curing Station. All the machines have been validated and approved by Henkel/Loctite and BASF Forward AM, who have officially become our business partners this year. Thanks to these partnerships, there are now many special engineering resins manufactured by these world’s leading companies available in our portfolio.

The collaboration with BASF Forward AM has also resulted in expanding our offer with metal 3D printing filaments for Zortrax Endureal industrial 3D printer. Two comprehensive sets, containing all the essentials to metal 3D printing, have been introduced as Zortrax Full Metal Packages, offering two different kinds of metal-polymer filaments to fit a wide range of engineering applications. Metal-polymer filaments are not the only novelty introduced for Zortrax Endureal, though, as VICTREX PAEK AM™ 200 has also joined the range of high-performance polymers dedicated to it.

New product launches aside, 2022 has been full of groundbreaking projects, industry fairs we’ve been a part of, and applications worth your while! Here’s a recap of all the key events of 2022!

Expanding Our Product Portfolio

1. Zortrax Powerful Trio

In 2022, we introduced a next-gen resin 3D printing and post-processing system: Zortrax Inkspire 2 UV LCD 3D printer, together with automated post-processing devices, Zortrax Cleaning Station and Zortrax Curing Station. The Inkspire 2 combines utmost precision with high speed and is compatible with a wide range of high-grade engineering resins by top global manufacturers, like Henkel/Loctite and BASF Forward AM. Through a detailed double-validation process, it is guaranteed that the prints, manufactured and post-processed with new Zortrax machines, meet all the properties declared for a given resin by its manufacturer. The range of technological advances, introduced in the Inkspire 2, translates into a huge step forward in Zortrax UV LCD solutions. Compared to the previous generation Inkspire 3D printer, the refined resin 3D printing system has:

7x more powerful UV light engine

40% more uniform UV light distribution

4x more build volume

Zortrax Powerful Trio, a comprehensive resin 3D printing and post-processing ecosystem, consists of Zortrax Inkspire 2 UV LCD 3D printer, Zortrax Cleaning Station, and Zortrax Curing Station.

#ZortraxPowerfulTrio has generated mass media coverage and evoked enthusiastic comments within the 3D printing community. Look at the exemplary publications covering the machines in the leading industry media:

- ALL3DP: https://all3dp.com/4/zortrax-targets-the-shop-floor-with-new-desktop-resin-3d-printer/

- 3D Printing Industry: https://3dprintingindustry.com/news/zortrax-launches-new-inkspire-2-uv-lcd-3d-printer-technical-specifications-and-pricing-214949/

- Develop3D: https://develop3d.com/3d-printing/zortrax-rolls-out-inkspire-2-uv-lcd-3d-printer/

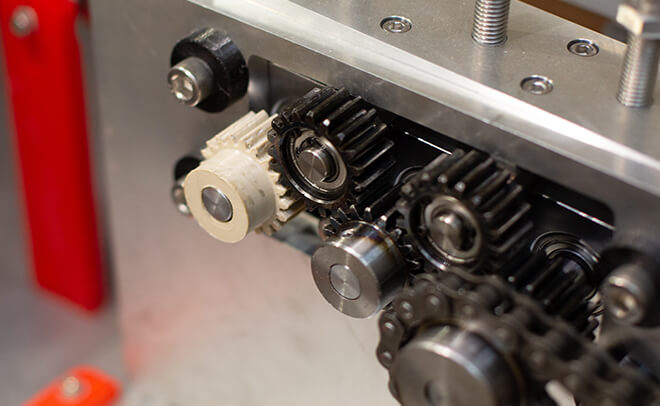

2. Zortrax Full Metal Packages

The passing year marked a milestone for Zortrax solutions dedicated to industrial applications, as, from now on, metal 3D printing is available on Zortrax Endureal. Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH are comprehensive sets, containing everything that’s needed for quality, convenient metal 3D printing. Each kit comprises, amongst other elements, BASF Forward AM’s filaments: either BASF Ultrafuse® 17-4 PH or BASF Ultrafuse® 316L. Using these metal-polymer filaments is an efficient manufacturing method to produce industrial-grade, stainless steel components. Compared to traditional production technologies, such as CNC machining or Metal Injection Molding, metal 3D printing ensures more flexibility of design, and most importantly, is much more affordable. While 3D printing with metallic powder filaments, however, it is vital to use a quality, reliable 3D printer, capable of processing them properly. It is also crucial to take care of proper post-processing – hence Zortrax Full Metal Packages includes a voucher which covers post-processing services at Elnik Systems GmbH in Germany.

Zortrax Full Metal Packages contain all the essentials for metal 3D printing, including quality metal-polymer filaments by BASF Forward AM.

3. VICTREX PAEK AM™ 200

Another novelty, introduced for Zortrax Endureal, is VICTREX AM™ 200 low-melt PAEK filament, a high-performance polymer that belongs to the same thermoplastics’ family as Z-PEEK. The most important features of VICTREX PAEK AM™ 200 FIL include low viscosity, assuring easier flow through the nozzle, slow crystallization rate facilitating strong interlayer bonding that improves tensile strength along the Z-axis, high dimensional stability, and minimized warpage.

“I’ve enjoyed seeing what the Zortrax Endureal 3D printer can do with an easier printing PEEK-based polymer like VICTREX AM™ 200, especially when combined with soluble supports. Overhang surfaces that are often a problem area in filament fusion have looked great, the Z-direction properties seem competitive, and some of the small precision samples Zortrax has made on the machine impressed me,” says Robert McKay, Victrex Head of Additive Manufacturing Business Development.

VICTREX PAEK AM™ 200 is an easier-to-print high-performance equivalent of PEEK, available for Zortrax Endureal industrial 3D printer.

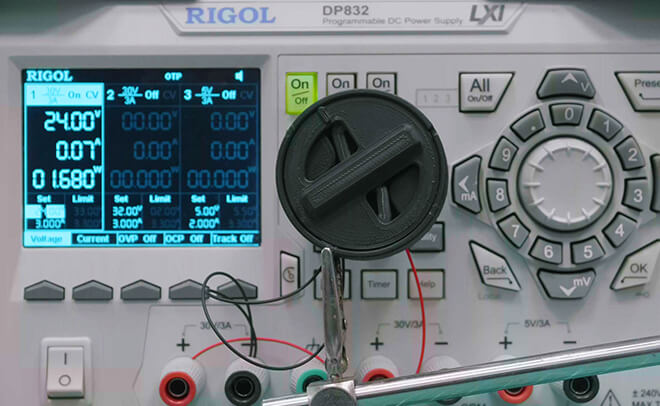

4. Z-SUITE 3.0 BETA

In a ’22 major update, the slicer has gained new, previously unavailable functionalities which help Zortrax 3D printers users prepare models for 3D printing more effectively. One of the main novelties is the Outer walls option, ensuring control over mechanical durability and dimensional accuracy of the target parts. One can now give prints extra strength and even better precision by increasing the number of printed contours. Z-SUITE 3.0 BETA also brings major changes and improvements to the key parameters, including Infill and Seam, and the prints’ overall quality.

5. New 3D Printing Profiles for M300 Dual

Another dual-extrusion 3D printer, Zortrax M300 Dual, in turn, has gained new printing profiles for external materials in Z-SUITE. The range of filaments has been extended with ones from such manufacturers as Kimya, Nanovia and 3DXTECH. Apart from Z-ULTRAT and Z-ASA Pro, Zortrax M300 Dual can now print on the BETA version with some more advanced, carbon-fiber-reinforced filaments, like BASF Ultrafuse PET CF15, 3DXTECH CarbonX PETG+CF, Kimya PETG Carbon or Nanovia PETG CF.

New Business Partnerships

1.BASF Forward AM

In 2022, we continued our long-term partnership with BASF, the largest chemical company in the world. Our goal here is to further expand the range of high-quality materials compatible with Zortrax machines.

BASF Forward AM is one of the largest suppliers of photopolymer resins for the Zortrax Inkspire 2, our latest high-end UV LCD 3D printer. Currently, the Inkspire 2 supports 12 different BASF Ultracur3D resins which have been calibrated and thoroughly tested by both Zortrax and BASF engineers.

Besides photopolymer resins, BASF Forward AM has a range of exceptional, high-end FDM filaments which are already available for Zortrax FDM 3D printers: Zortrax Endureal and Zortrax M300 Dual. BASF metal-polymer filaments included in Zortrax Full Metal Packages are a perfect fit with Zortrax Endureal. Automotive-grade filaments like BASF Ultrafuse PP GF30 and BASF Ultrafuse PAHT CF15 are already calibrated and available for the Zortrax M300 Dual 3D printer.

The picture shows Zortrax and BASF representatives during Formnext 2022.

2. Henkel/Loctite

Zortrax 3D printing resins portfolio has been extended by cooperating with another top global brand: Henkel/Loctite.

“We engaged with Zortrax a few years ago when they decided to open their system to industrial-focused materials and re-design their system towards the engineering and industrial users. It is worth mentioning that Zortrax focuses on, in addition to print performance, an integrated solution including post processing. They were taking a new approach, and we wanted to be a part of that process as a high-performance material provider,” says Maarten Adolf, Senior Business Development Manager – 3D printing Europe at Henkel AG & Co. KGaA.

The selection of 3D printing photopolymers in our portfolio includes Tough resins, which endure significant loads before they break. Hence, they are perfect for 3D printing mechanically strong, wear and tear resistant, load-bearing components.

3. VICTREX

Victrex is a world leader in PEEK and PAEK-based polymer solutions. We’ve teamed up with the company in 2022 and launched VICTREX AM™ 200, a high-performance PAEK polymer that has been designed for extrusion-based 3D printing from the ground up.

Groundbreaking projects

1. Z-PEEK certified by ESA

In 2022, our high-performance filament, Z-PEEK has met the stringent outgassing requirements and has been certified to the European Space Agency standard. Therefore, this high-temperature filament, compatible with the Zortrax Endureal industrial 3D printer, joined the few polymers that are suitable for use in space.

Z-PEEK has passed the stringent tests at ESA and is therefore officially qualified for use in space.

„Compliance with outgassing requirements is absolutely crucial when it comes to providing materials for space industry. Having those properties confirmed by tests done at ESA’s ESTEC facilities and getting an official report from those tests enable us to provide more value to our most demanding customers” says Michał Siemaszko, Head of Research and Development Department at Zortrax.

Read the report issued by ESA qualifying Z-PEEK for space applications here.

2. 4D printing in a joint project with ESA

First successful demonstrators with electrically activated movement have been 3D printed on Zortrax M300 Dual 3D printer under a European Space Agency contract. 4D printing technology means that 3D models can change their geometry under the influence of external stimuli (e.g., structures that fold when the ambient temperature falls below a certain value, or mechanisms in which movement is activated electrically). In this joint project, the 4D printing capability was achieved using multi-material printing feature currently under development for Z-SUITE software.

Zortrax engineers, together with ESA specialists, have developed 4D printing technology, in which the models change their shape under external stimuli.

3D Printing Events

1. Formnext 2022

This year, we once again exhibited at the renowned, international 3D printing fair, Formnext 2022 in Frankfurt. We officially presented our new products, including Powerful Trio there. We also showed Zortrax Inkspire 2 Clinical, a brand-new 3D printer and complementing software to bring new quality to 3D printing for the medical sector. The printer is set to go on sale in 2023. Formnext 2022 was an excellent opportunity to experience the capabilities of the machines and top-grade materials live and learn more about their features from both Zortrax and our partners’ representatives.

Zortrax Powerful Trio has garnered true interest during the international 3D printing fair, Formnext 2022.

2. IEEE Conference in the USA

Zortrax specialists participated in IEEE Aerospace Conference 2022 in Big Sky, Montana, one of the most important conferences in the world dedicated to the latest aerospace research. Michał Siemaszko, Head of Research and Development and Jacek Krywko, Leader of Advanced 3D Printing Solutions, depicted there the results of Zortrax engineers’ work on composite 3D printing in double extrusion in cooperation with European Space Agency. At the conference, Michał Siemaszko also presented a research paper entitled “3D Printing CubeSat Parts with Power and Data Transfer Functionalities with Two Blends of PEEK”, which describes the results of exhaustive tests performed at ESA’s facilities that Z-PEEK has passed, qualifying it for space applications.

The outgassing property test report is available here.

3. Warsaw Industry Week

In November, our Official Distributor in Poland, 3Druktronik, took part in Warsaw Industry Week, international industry fairs. During the event, the company exhibited all Zortrax machines, working in four different technologies (UV LCD, LPD, LPD Plus, and SVS).

In addition to the aforementioned, the Zortrax brand was a part of many other events in 2022, where our distributors and resellers presented our offer, novelties and solutions. Check the full list of events in 2022 at our blog.

Interesting Use Cases

1. Maciej Szczepański – prostheses for dogs / medicine

2. Custom bike lamps by Krzysztof Urban / engineering

3. Pistol grip for an Olympic athlete by Athletics3D / sports

https://zortrax.com/blog/3dprinted-custom-biathlon-rifle-handstop/

4. Quandum Aerospace / aerospace

https://zortrax.com/blog/quandum-aerospace-tested-with-zortrax-resin-3d-printing-ecosystem/

5. ABLAB mock-up/ design, industry, manufacturing

https://zortrax.com/blog/how-3d-printing-helps-to-plan-the-layout-of-production-lines-in-factories/

As 2022 has shown to us all, 3D printing continues to innovate, improving various businesses as well as the lives of individuals. We’re glad that we are the part of this ever-growing industry.

We’re looking forward to even more exciting projects in 2023!

For even more interesting user stories, go to our Zortrax blog.