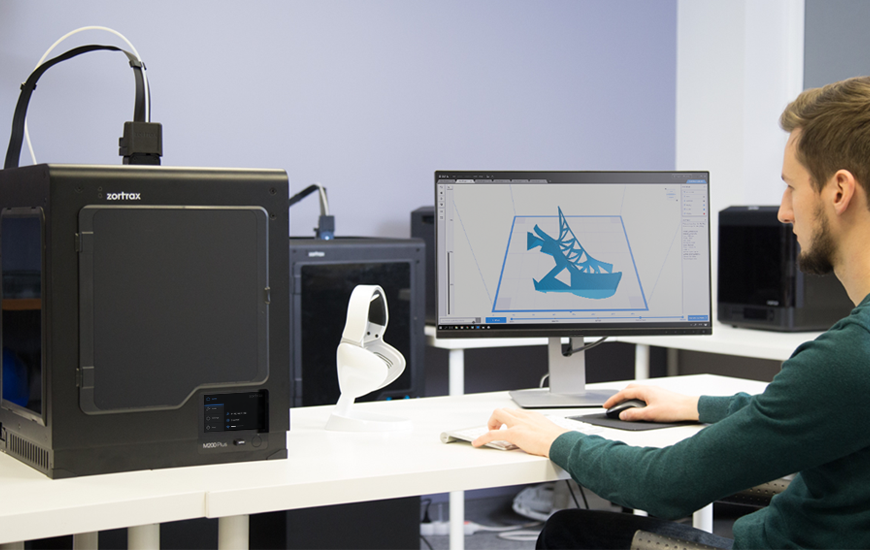

Zortrax M200 Plus – Next Level of 3D Printing

Zortrax M200 Plus is a professional LPD (FFF) 3D printer designed mainly for business clients. Based on the award-winning Zortrax M200, the M200 Plus introduces top of the class touch screen, quad core processor, and an ability to 3D print with flexible materials. Furthermore, WiFi and Ethernet connectivity enables remote control of multiple devices working together. Driven by vision of large, automated 3D printing farms, we have set our design goals. Wireless connectivity was just the beginning. To ensure seamless operation of such farms, the Zortrax M200 Plus had to be even more reliable and require even less maintenance than the M200. That’s precisely what we have achieved.

Heritage of Quality

The M200 was a groundbreaking product that has established Zortrax as one of the key players on the global 3D printing market. Exceptional build quality, reliability, and dedicated software fine-tuned to work with a range of various dedicated materials in the so called Zortrax Ecosystem were among the M200’s defining features. The printer has won numerous industry awards and, most importantly, the trust of our customers. It was a bestseller. Even today the M200 is still one of the world’s best desktop 3D printers. Making it even better was quite a challange.

But we have never stopped innovating. A lot has changed since we introduced the M200. Besides positive feedback, we have also received plenty of invaluable suggestions from our customers. The 3D printing technology has moved forward. New materials have been introduced, the need for automation in manufacturing processes is on the rise, 3D printers are becoming more and more ubiquitous. We had to get the M200 ready for the new reality.

Hardware

The experience gained in developing the M-series 3D printers has led to significant changes in the extruder and hotend design. The M200 Plus is fitted with a new, additional centrifugal fan to better dissipate heat generated in the XY block where the upper part of hotend is attached. This way we have made the entire system even more reliable.

To further improve extrusion efficiency, we have redesigned the geometry of the filament drive mechanism. Changes prevent the material from folding around the extruder’s cogwheel and getting stuck in there. We have also added an additional cooling fan pointed at the model being 3D printed. The Zortrax M200 Plus has two such fans which leads to better retraction i.a.

New, better Hotend V3 is our last change in the extruder. We have solved the issue with a teflon pipe slipping out and modified the thermal intermediate zone to improve reliability and quality of prints. An upgraded nozzle guarantees more precise extrusion. Furthermore, by making the aluminum block smaller we have achieved improved heat dissipation and shortened the heating-up time. Caps attached to the nozzle and bottom part of the hotend prevent dirt from getting inside and damaging the mechanism. Finally, the redesigned extruder allowed for broadening the range of supported materials which now includes Z-SEMIFLEX, among others.

But we didn’t stop there. Filament endstop significantly reduces the number of failed prints. When the material runs out, the M200 Plus will pause the print and notify the user about the need to load up a new spool. Following our users’ suggestions, we got rid of the SD card and fitted a USB port instead. Now it is possible to upload a model directly from the USB storage device of any kind.

Our next update is a touchscreen. Navigating through available options is now faster and more intuitive. Moreover, we will add new interface functionalities with firmware updates that now can be done automatically over WiFi. We have also removed the small connector from the perforated build platform to prevent it from getting damaged when users take their prints out of the printer.

Additional changes include a new spool holder and plates shielding the Z axis to improve users’ safety and reliability of the build platform. Last but not least, you can now monitor your prints in Z-SUITE with a built-in camera.

Software

Due to WiFi and Ethernet connectivity, one ZCODEX file can be easily uploaded to multiple 3D printers from one computer. Once the file is created in Z-SUITE, you can also copy it to any USB storage device and upload it directly using the M200 Plus menu. Furthermore, you can now remotely start and pause the print in Z-SUITE.

Z-SUITE also has a separate control board for each of the connected M200 Plus where you can find details such as the type of loaded material or 3D printing progress. Here you can also see the print through the built-in camera mentioned above.

Materials

Currently, the Zortrax M200 Plus supports all materials dedicated for M-series 3D printers like highly appreciated Z-ULTRAT or commonly used Z-ABS. Moreover, the printer also supports Z-SEMIFLEX, a semi-elastic material our users have been waiting for nearly since the introduction of the M200. Hardware changes let the M200 Plus effortlessly print high-quality, precisely made models out of Z-SEMIFLEX. Importantly, improvements also enable users to experiment with various third-party materials without compromising quality and reliability of their prints. 3D printing with dedicated Zortrax materials remains at the same, top of the class level.

There is a lot we have learned working on the M200. All these years of experience led to the M200 Plus, a reliable, future-proof professional 3D printer.