Zortrax Rocks at Formnext 2016. Join Us in Frankfurt!

And so we meet again. It’s gotten noticeably colder since the last time we saw each other at TCT Show in Birmingham. Thankfully the dropping temperatures didn’t deter you from meeting us in Frankfurt am Main in Germany. We’re so glad you’re here, because Zortrax at Formnext is a treat you wouldn’t want to miss. Trust us or see for yourselves below. Better yet, come by because as usual we’re waiting for you and it’s the last opportunity to meet us this year.

Zortrax stand at Formnext 2016

We’ve Been Here Before

We’re not new to the Formnext trade fair. Last year’s edition was certainly entertaining and informative for both you and us. The event covers all the subjects we’re interested in. That obviously includes additive manufacturing but also industrial tooling, e.g. molding, design & product development and many more you just have to check if you’re here. Having great memories from last Formnext, our Team made sure this year is even better than the last one. Let us give you a little foretaste of what waits for those of you who will be joining us in Frankfurt. One of the less standard ways of finding our stand is to let your nose be your guide. The aroma of freshly brewed coffee wafting in the air will lead you straight to our barista. So, enjoy a cup of the strong, dark liquid, let it warm you and allow the caffeine to kick in. Now, let us show you what we’ve got.

Zortrax Motorcycle

All-Star Team

We’re highly critical of our work and that’s why not all of our models made the Frankfurt roster. We drafted only the best from the best to show you here and to accompany our 3D printers: M200, M300 and Inventure. The projects that will surely catch your eye as first are our biggest ones. The amazing motorbike, or Z-Ride as we call it, and the already well-known menacing yet stunning Superhero. But as we’re strong advocates of applying 3D printing technology and Zortrax Ecosystem solutions to multiple branches, we made sure industries like medicine, engineering, architecture, industrial design and consumer products also have their respectful representatives. That’s why when being at our stand, you find yourself surrounded with multiple models. Some of them might be already familiar to you as we featured them at our blog. You can learn more about medical winch, artificial heart, angle grinder and gear in our articles. At our stand, though, you will also find the architecture mockup and speakers that will probably encourage you to make a sound, the ‘wow’ one. And that’s not all.

Rookie Time

Hopefully, you’ve had a chance to know us a bit and already noticed that we don’t like to sit idly. We have a lot of ideas that we itch to turn into shapes to share with you something special. Events like this one only propel us to put even more effort into amazing you as we can see your interest and reactions to our projects in real life and that in turn gives us a huge motivation boost. So, although we’re partial to our so-far-favorites, it’s time to make some room for our two newest models’ and let them shine. They certainly deserve your undivided attention, see for yourselves.

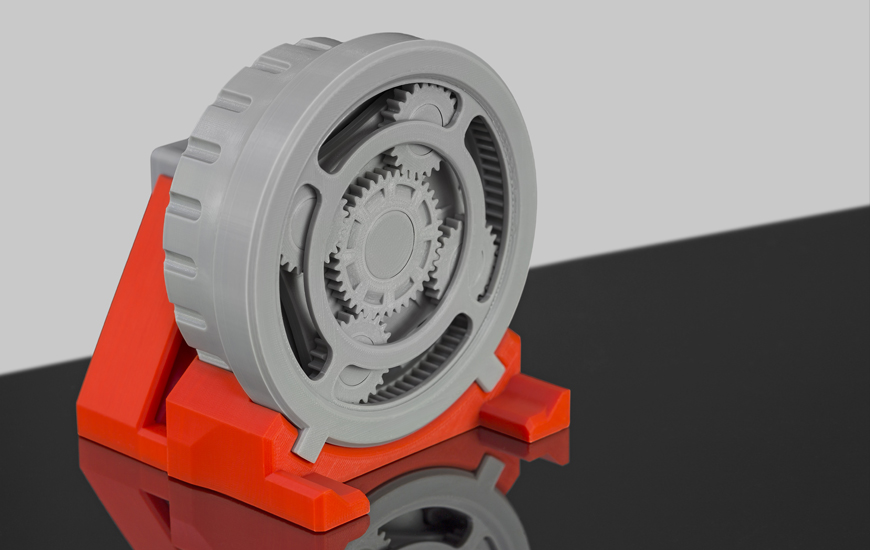

Cycloidal drive

Clockwork Precision

Although at first it may seem inconspicuous, our newest model 3D printed on Zortrax Inventure is anything but that. Don’t underestimate our little gear as it has a lot of potential hidden in the compact size. Those of you familiar with robotics, engineering or automotive industries probably instantly recognized it as a cycloidal drive aka a cycloidal speed reducer. But what will probably interest you the most is the fact that the whole mechanism was printed in Z-ULTRAT Plus as one element thanks to DSS technology. Let’s remind that Z-SUPPORT material dissolves when put into a special solution. In practice, it means it does all the usual work concerning residue removal for you, leaving you with a high precision 3D print. Just take a look. Since we like utilizing different materials in our models, the drive’s base was 3D printed in red Z-ABS on Zortrax M200.

Absorber spring 3D printed with Z-HIPS

Less of a Shock

Or is it? This shock absorber model was entirely 3D printed on Zortrax M200 with the use of materials from our range. All of them have different properties that combined can give you an exceptional result. We decided to 3D print the absorber’s spring using Z-PETG. The material’s durability and high elasticity made it perfect for the part. Also, a little inside tip, we printed the element horizontally to get the best possible effect. To diversify the color scheme, the piston and the stop were printed in yellow Z-ABS. The other parts of the model, including servo motor casing, were printed in Z-HIPS due to its stunning durability. We chose the material in black to complement the model with modern matte finish.

We Will Rock You

Another country, another city. Sometimes we get a feeling it’s a bit like we’re on a mini world tour. Although we’re obviously not professional perfomers, your interest, attention and reactions make us feel like rock stars. It’s just the second day here at Formnext and you’ve already made this event special and given us every reason to stay really busy. But, as we like challenges, we’re ready and waiting for more. If you still haven’t had the opportunity to meet us in Frankfurt and happen to be nearby, drop by booth E24, Hall 3, Messe Frankfurt and let us rock your world. We’re waiting for you ‘til Friday.