What Makes Zortrax Inventure a Professional Dual-extrusion 3D Printer

Summary

- Zortrax Inventure is an advanced desktop 3D printer with dual-extrusion system, heated chamber and HEPA filter.

- The main advantage of the 3D printer are the water-soluble support materials, which are 3D printed simultaneously with base filaments.

- Dedicated support removal device—DSS Station allows you to streamline the process even further.

Zortrax Inventure is a dual-extrusion 3D printer we have designed for professional applications in various fields ranging from industrial design, through medicine, to engineering.Our goal was to build an affordable desktop machine with capabilities one could find almost exclusively in large industrial 3D printers costing hundreds of thousands of dollars: a dissolvable support system, heated chamber, and HEPA filter. We have achieved that in Zortrax Inventure 3D printer.

LPD Plus Technology

While M-series 3D printers are award-winning prosumer class devices, Zortrax Inventure is a fully fledged professional machine. It’s all about taking it a little bit further. All our products are designed for precision, but when you prototype high-performance engines even the tiniest distortion can make the difference. Same thing when you need 3D printed models based on CT scans at a hospital. Imperfections mean less accurate training models for medical staff which makes their work more difficult. Similarly, when you 3D print complex organic shapes of tentacled monsters or dragons, the M-series machines will serve you well. But when you are a professional model maker and those monsters can make it or brake it for a multi-million dollar blockbuster movie, you have to get them exactly right. Professionals always need a little more. That’s why we have developed the Layer Plastic Deposition Plus (LPD Plus) technology for the Zortrax Inventure. Here’s how it works.

Imperfections mean less accurate training models for medical staff which makes their work more difficult. Similarly, when you 3D print complex organic shapes of tentacled monsters or dragons, the M-series machines will serve you well. But when you are a professional model maker and those monsters can make it or brake it for a multi-million dollar blockbuster movie, you have to get them exactly right. Professionals always need a little more. That’s why we have developed the Layer Plastic Deposition Plus (LPD Plus) technology for the Zortrax Inventure. Here’s how it works.

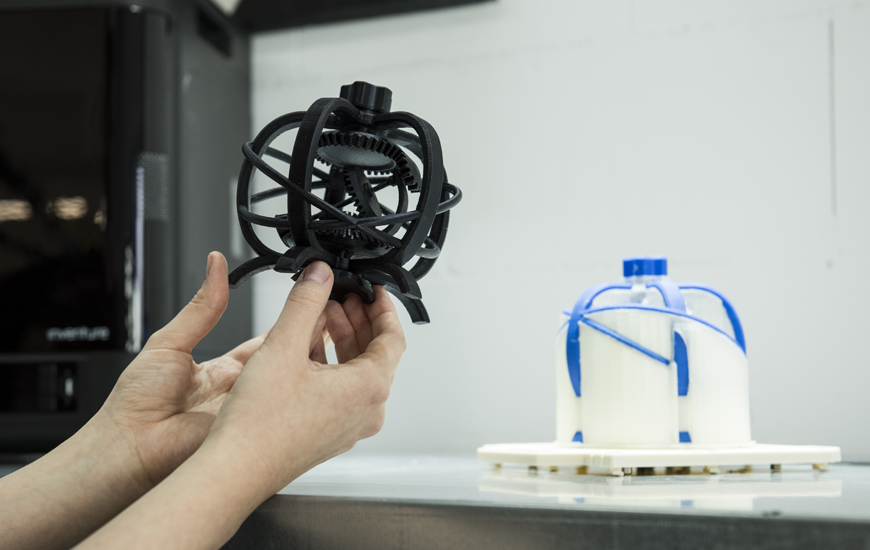

Water-soluble Support

Support removal is a step you almost always have to take when the 3D printing of your model is done. In a single-extrusion 3D printer, support structures are made of the same materials as the model itself and have to be removed manually. While usually it’s not that much of an issue, there are cases where mechanical support removal is simply impossible. Models with complex internal architecture, like the human heart, can’t be 3D printed in a standard LPD technology because most of support structures would end up inside the model where they couldn’t be reached with pincers. So, Zortrax Inventure 3D prints support structures with separate, water-soluble PVA support materials: Z-SUPPORT and Z-SUPPORT Plus. Water can remove support structures even from almost inaccessible places, leaving all surfaces intact.

Models with complex internal architecture, like the human heart, can’t be 3D printed in a standard LPD technology because most of support structures would end up inside the model where they couldn’t be reached with pincers. So, Zortrax Inventure 3D prints support structures with separate, water-soluble PVA support materials: Z-SUPPORT and Z-SUPPORT Plus. Water can remove support structures even from almost inaccessible places, leaving all surfaces intact.

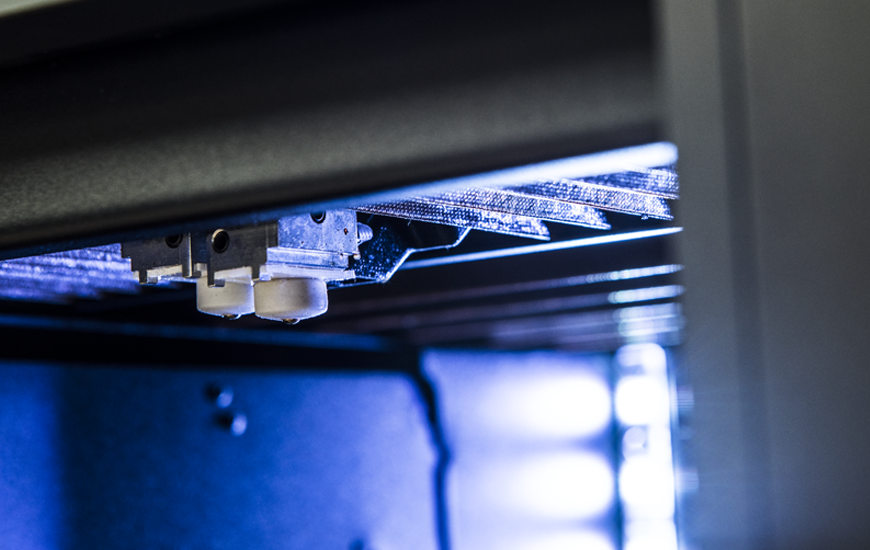

Advanced Dual-extrusion

To make 3D printing with separate, water-soluble support material possible, we have designed a unique dual-extrusion system. Usually, dual-extrusion machines work with two extruders, one for each material the 3D printer prints with. To reduce the mechanism’s size and weight, we have solved the dual-extrusion with just one extruder that feeds two 3D printing materials to their respective nozzles. Those nozzles are set at a fixed distance apart in XY plane which increases precision and repeatability. This way we could make Zortrax Inventure more affordable and easier in XYZ calibration. Advanced extruder can also easily handle flexible materials like Z-SEMIFLEX.

Those nozzles are set at a fixed distance apart in XY plane which increases precision and repeatability. This way we could make Zortrax Inventure more affordable and easier in XYZ calibration. Advanced extruder can also easily handle flexible materials like Z-SEMIFLEX.

Enclosed Printing Chamber

All ABS-based materials shrink during cool-down. This effect can be significantly reduced though by keeping the temperature right in the material’s optimal range. That’s why we have designed Zortrax Inventure around an enclosed, heated printing chamber. Once you close the door, the chamber is practically sealed off from the surrounding environment to ensure tightly controlled 3D printing conditions. It’s way easier to avoid sudden temperature drops caused by moving air. That’s why Zortrax Inventure can flawlessly 3D print with materials particularly sensitive to temperature changes like Z-ULTRAT Plus.

Once you close the door, the chamber is practically sealed off from the surrounding environment to ensure tightly controlled 3D printing conditions. It’s way easier to avoid sudden temperature drops caused by moving air. That’s why Zortrax Inventure can flawlessly 3D print with materials particularly sensitive to temperature changes like Z-ULTRAT Plus.

HEPA and More

Zortrax Inventure’s enclosed printing chamber makes it possible to guide most of the air coming from the inside through a built-in HEPA filter which effectively catches more than 99% of 3D printing emissions, including ultra fine particles below 100 nm in diameter.

3D printing materials dedicated for Zortrax Inventure come in Smart Cartridges that inform you about the type of material inside and whether it is about to run out. Last but not least, we have designed the Zortrax DSS Station, an easy to use device for automatic water-soluble support removal. Just set it up, fill it with water, put the model in, and take it out nearly support-free after a few hours. There are 3D printers on the market which have one or two of the above mentioned features. What makes Zortrax Inventure truly exceptional is that it has all of them combined and seamlessly integrated in the entire Zortrax Ecosystem along with dedicated 3D printing materials and Z-SUITE slicing software. That’s how we have achieved an industrial-class performance in a user-friendly plug & play machine that fits on your desk.

There are 3D printers on the market which have one or two of the above mentioned features. What makes Zortrax Inventure truly exceptional is that it has all of them combined and seamlessly integrated in the entire Zortrax Ecosystem along with dedicated 3D printing materials and Z-SUITE slicing software. That’s how we have achieved an industrial-class performance in a user-friendly plug & play machine that fits on your desk.

Order Zortrax Inventure here.

Order Zortrax Inventure with DSS Station here.