Ceramic-Filled Resin Now Available for Zortrax Inkspire 2

Summary

- Zortrax is introducing an industrial-grade, ceramic-filled 3D printing resin — BASF Ultracur3D® RG 3280 for Zortrax Inkspire 2,

- 3D models made with BASF Ultracur3D® RG 3280 can be post-processed in Zortrax Cleaning Station and Zortrax Curing Station, making it possible to acquire ceramic-like parts,

- The resin has exceptionally high stiffness, excellent resistance to high temperatures, and Shore hardness (D) reaching 96.

As the next stage of Zortrax and BASF Forward AM’s partnership, we are extending the range of resins validated to work with our refined resin 3D printing and post-processing system — Zortrax Powerful Trio, encompassing Zortrax Inkspire 2, Zortrax Cleaning Station and Zortrax Curing Station. Our newest resin 3D printer gains a 3D printing profile for BASF Ultracur3D® RG 3280 — a unique photopolymer resin with ceramic particles. Read on to learn more about this high-performance material for industrial applications.

Ceramics in Industrial Applications

Ceramic materials are heavily used in many branches of industry mainly due to their resistance to all kinds of wear, such as corrosion, shape change, melting, stretching and distortion. In comparison with other materials, such as stainless steel, ceramics components offer very good strength-to-weight ratio, which makes them easier to handle. As a result, ceramic parts are employed in many manufacturing processes, where they provide highly desirable mechanical, electrical, thermal, and chemical properties. Essentially, ceramics show great potential in aerospace, automotive, robotics, electronics, metallurgy, energy production and chemical industry.

Now, devices included in our new resin 3D printing and post-processing system gain the ability to fabricate 3D parts that closely resemble ceramics. It becomes possible with the use of BASF Ultracur3D® RG 3280 3D printing resin which we have thoroughly validated. Starting from today, its calibrated profile can be found in Z-SUITE 3D printing software with 0.05 mm layer thickness.

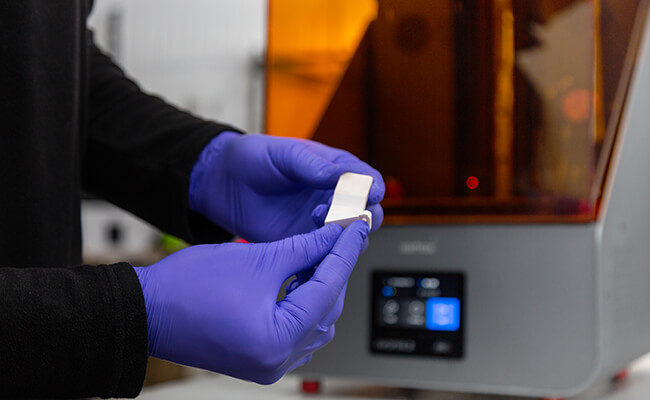

Zortrax Inkspire 2 resin 3D printer now works with BASF Ultracur3D® RG 3280 ceramic-filled photopolymer resin.

Intuitive Z-SUITE Features for 3D Printing Photopolymers

Preparing models in Z-SUITE when working with photopolymers like Ultracur3D® RG 3280 has been made more convenient and easier. The slicing software not only gains a ready, calibrated profile, but also a notification with suggestions for proper post-processing steps to be performed once the 3D printing has been finished. Thanks to that, the users know the exact cleaning and curing times of their 3D prints. For parts made with Ultracur3D® RG 3280, post-processing in Zortrax Cleaning Station takes about 10 to 20 seconds, whereas in Zortrax Curing Station it can take about 30 minutes for each side of the model.

Watch the video below to see how easy it is to fabricate ceramic-like parts using Zortrax Inkspire 2 resin 3D printer together with two post-processing devices: Zortrax Cleaning Station and Zortrax Curing Station. The video show the process of 3D printing, cleaning and curing an exhaust mixer used in modern drones.

Ultracur3D® RG 3280 3D Printing Photopolymer Resin: Main Features

Ultracur3D® RG 3280 is a specialized, ceramic-filled resin belonging to the rigid line of BASF Forward AM’s 3D printing photopolymers. When used with Zortrax Inkspire 2, it offers our users the possibility of 3D printing unique parts which, after proper post-processing in Zortrax Cleaning Station and Zortrax Curing Station, gain properties similar to ceramics. And it can take place without the use of specialized furnaces. It is, however, important to remember that you have to remove the support structures right after the 3D printing process, as after the post-processing stages it won’t be possible. The target 3D prints are white and have a characteristic, ceramic look to them.

3D parts made with BASF Ultracur3D® RG 3280 ceramic-filled resin have properties similar to ceramics and have a characteristic look to them.

Despite the high particle content, the Ultracur3D® RG 3280 resin has low viscosity and its sedimentation in the vat is limited, which leads to maximized ease of use and print quality. The material is versatile and opens up a wide application possibilities thanks to a very interesting set of properties. You can read more about them below.

Rigidity and Electrical Voltage Insulation

Parts 3D printed with RG 3280 exhibit high stiffness (up to 10 GPa) and electrical non-conductivity. The resin can therefore be used to 3D print objects required for specific manufacturing processes, for example, ceramic handling arms that move semiconductor wafers from one station to another. Other applications may include positioning and guide pins used in pressure welding. Such parts can function as a non-conductive, thermal insulation which doesn’t interfere with the welding process.

Heat Deflection Temperature and Chemical Resistance

With HDT values reaching 132 °C at 1.82 MPa and 280 °C at 0.45 MPa, models 3D printed with the Ultracur3D® RG 3280 resin can withstand high temperature operating conditions. So, they can be used for thermal shields, engine systems, turbine components, high-performance parts, or injection molds intended for high temperature molding. Additionally, such parts have outstanding chemical resistance to many industrial fluids, such as acetone, engine, hydraulic and transmission oils, brake and cooling fluids, and multi-purpose fats.

We highly encourage you to try out BASF Ultracur3D® RG 3280 resin with your Inkspire 2 and post-processing equipment. The whole procedure using these three devices lets you fabricate highly precise and wear resistant 3D parts with unmatched properties.

For more detailed information about our high-end resin 3D printer and post-processing devices – Zortrax Inkspire 2, Zortrax Cleaning Station and Zortrax Curing Station – go to: Zortrax Inkspire 2 product page.