The Summary of 2023 at Zortrax

New Business Partnerships

-

Cooperation with AM-COE

This year, we have started a partnership with AM Centre of Excellence (AM-COE), a British company specializing in the production of light-cured ceramic resins for prototyping and 3D printing in the aerospace, electronics, chemical and automotive industries. The joint project involves the development and implementation of a new ceramic 3D printer that will support manufacturers looking for a simple-to-use and affordable machine for mass production. Such a professional machine for handling advanced ceramic resins can be made thanks to both companies’ resources. Zortrax has the necessary experience in developing high-quality 3D printers, automatic post-processing devices, a wide range of resins, as well as printing software to support resin 3D printing. AM-COE, in turn, owns professional research facilities and has the key capabilities to produce specialty resins.

-

A PLN 5 mln Investment Agreement

On November 15, 2023, Zortrax signed an investment agreement under which a stock market investor, Artur Błasik, will commit PLN 5 million to the company. The financing provided will allow Zortrax to take advantage of the opportunities related to the dynamic development of 3D printing and help the company return to the path of growth. As the investor underlined: “Zortrax is a company with great potential, global reach and its own research and development facilities. In my opinion, it is undervalued by the capital market. I believe that with the new financing structure it will be able to benefit from the dynamic development of the entire 3D industry.”

Product Portfolio Expansion

-

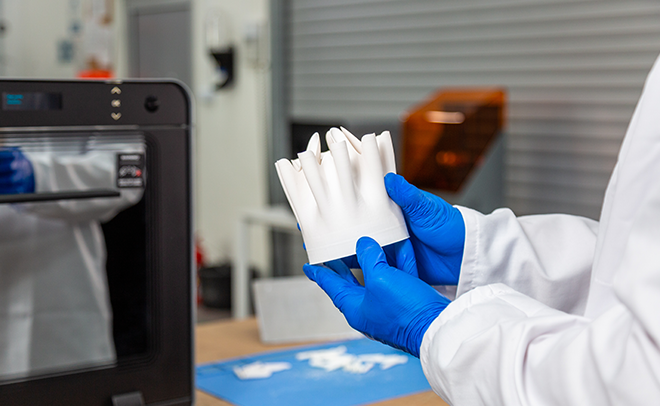

Ceramic-filled 3D Printing Resin

As the further stage of Zortrax and BASF Forward AM’s collaboration, the portfolio of 3D printing resins, validated to work with Zortrax Powerful Trio, has been extended with a specialized, ceramic-filled photopolymer – BASF Ultracur3D® RG 3280. With Zortrax Inkspire 2 resin 3D printer, the users can manufacture parts which, after proper post-processing in Zortrax Cleaning Station and Zortrax Curing Station, gain properties similar to ceramics, without the need to use special, costly furnaces.

-

Speed Mode Feature Premiere

In Spring 2023, Zortrax desktop 3D printers became faster than ever thanks to a new Speed Mode feature. It has been introduced as a 100% free feature, available for all users with the firmware update. To cater to our community’s expectations, Zortrax FDM 3D printers – Zortrax M300 Dual, Zortrax M300 Plus and Zortrax M200 Plus gained the accelerated printing option, enabling up to 3x faster 3D printing. Speed Mode ensures greater design flexibility, helps optimize manufacturing processes, and lets one produce more units in shorter time. The new feature is invaluable especially for those companies that offer 3D printing services or run 3D printing farms, manufacturing many 3D parts daily.

-

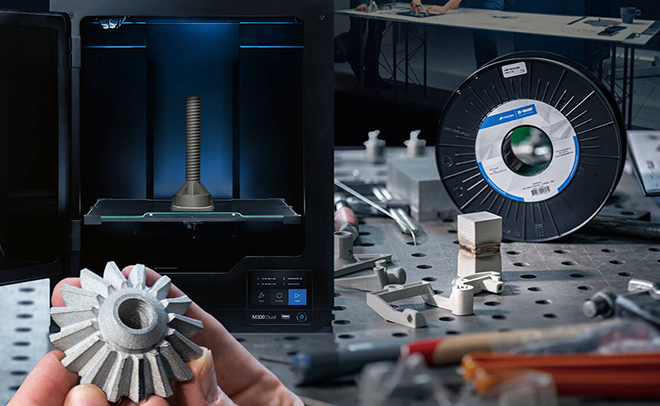

Metal 3D Printing Capability for Zortrax M300 Dual

This year, metal 3D printing option, apart from the industrial Zortrax Endureal 3D printer, has also become possible on a versatile desktop Zortrax M300 Dual machine. Zortrax engineers have developed and optimized 3D printing profiles for two metallic-powder filaments: BASF Ultrafuse® 316L and BASF Ultrafuse® 17-4 PH. With Zortrax Full Metal Package we have introduced all that is necessary for the smooth metal 3D printing process, resulting in fully functional parts exhibiting the properties of steel that can be welded, smoothed, or polished.

-

KIMYA ABS-ESD New Profile

Yet another new material profile – KIMYA ABS-ESD, has appeared in Z-SUITE software, joining the list of Zortrax M300 Dual-compatible materials. ABS-ESD is based on ABS and enriched with special additives which ensure that prints made with this filament do not electrify. It is hence ideal for printing all kinds of parts that come into contact with electrostatic-sensitive equipment and electronic components (housings, containers, feeders). It is also easy to print, impact-resistant and mechanically durable.

-

Flame-retardant Polymers for Zortrax Endureal

We have not forgotten about our industrial users, either, and introduced several advanced polymers with flame-retardant properties to our portfolio. Zortrax Endureal gained calibrated, ready-to-use profiles for BASF Ultrafuse® PPSU, BASF Ultrafuse® PC/ABS FR, and Nanovia PC-ABS V0, which joined the broad range of materials for specialized applications. All these filaments are recommended for conditions with increased fire risk. BASF Ultrafuse® PPSU and BASF Ultrafuse® PC/ABS FR have additionally been certified for railway use, meaning you can safely use them to print certain railroad vehicles’ components.

3D Industry Events

-

Formnext 2023

Like every year, in November, we exhibited at the international 3D printing Formnext fair in Frankfurt. This time, we shared the booth with our partner, 3D Prima to show both industrial and desktop 3D printers, post-processing machines, and tell the interested all about our novelties: metal 3D printing, the Speed mode, new printing profiles for flame-retardant filaments and ceramic-filled resins. During four days of this 3D printing holiday, on November 7-10, our team met with Zortrax resellers, strategic and marketing partners, industry media representatives, and material manufacturers. Over 840 exhibitors and more than 30,000 visitors gathered at Messe Frankfurt to celebrate additive manufacturing!

We’re looking forward to the exciting projects in 2024!

Find out more about Zortrax products and read interesting 3D printing stories on Zortrax blog.