Post-Processing the 3D Print — Zortrax Support Center Manuals

Those of you who visit our blog regularly should be already familiar with the fact that we really appreciate post-processing, especially a well done one. By sharing with you the silhouettes of our users and their art we want to promote their talent and also the various possibilities to modify the finished look of the 3D printed models. Apart from the fancy pieces from our blog we want to show you the key elements of the process itself.

Get Prepared

Before we start thinking of any activities that are to improve the look of the 3D print, we need to focus on the very designing stage. More advanced users can simply design the object in such way that the model will be 3D printed almost without support, or create and set the position of the model in such way, that the support material will be generated only in the places that are not visible, e. g. in holes or covered surfaces. Another vital thing is the support angle that can be modified in Z-SUITE. Zortrax M200 users can choose from 30 to 80 degrees or select the Lite support which is easier to remove. However, in case of the Inventure 3D printer, getting rid of the support will be much easier thanks to the DSS solution that allows fast and almost hands-free removal of the soluble support just by putting the 3D print in a special container filled with water-based solution. The factor that also influences the quality of the object is also layer thickness that simply determines the look of the surface.

Is Post-processing Necessary?

Just take a look at our users models to see the power of post-processing techniques, which apart from giving your model additional color and ultra smooth surface, can actually make it look as an end-use product. Obviously, post-processing is not obligatory if you only want to check the functionality ant the real dimensions of the model, or when the shade of the product are not a matter of a great importance. Having the access to the Zortrax M200 3D printer already gives you the chance to use multiple colors, with materials like Z-ULTRAT you can even choose from the palette that includes 15 different shades. When it comes to the texture of the print, again the users are given the opportunity to select particular Zortrax materials to obtain the desired effect: matt, shiny or semi-mat finish.

Start from the Basis

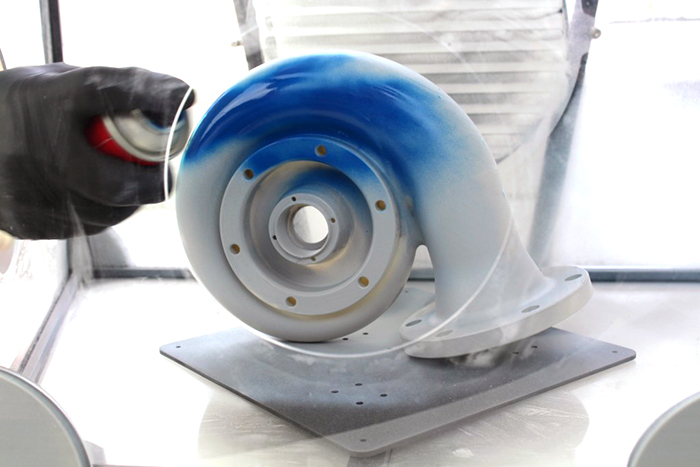

All of you who are new to the topic of post-processing or want to grab a solid piece of knowledge concerning the issue can visit our Zortrax Support Center. In various manuals the users can learn about the post-processing techniques and the methods to prepare the models for the treatment. Activities like gluing, acetone vaporizing, polishing, painting or spackling are clearly described in a form of simple steps. Those of you who want to have their own hard copies of them can easily generate a PDF file and print it just by clicking on a PDF icon in the right upper corner of the screen. All the articles contain the list of necessary tools and materials required to obtain optimum results and also tips from Zortrax team.

Replace the Expensive with Your Own

Make your prototypes as similar to the commercial goods as they can be. With high quality Zortrax printing materials that allow easy post-processing you can create models with ultra-commercial look. LPD technology incorporated by Zortrax M200 device is in fact a great opportunity to make inexpensive prototypes that can be well used for the purpose of product evaluation instead of for example their injection molded equivalents.

Needless to say that post-processing and designing models for 3D printing became a real hobby of many users who constantly give us plenty of inspiration and show us that thanks to the use of 3D printing they could discover the new approach towards various industries and perform their work more efficiently. Being able to came up with affordable 3D printed prototypes that resemble the look of commercial products, lots of engineers, designers and artists were able to find a new vent for their talent and skills. If you want to get to know the post processing techniques and see a chance for yourself to give your prints the most desired look visit the Zortrax Support Center.