Empowering Industry with the Electrostatic Protection – New Z-ESD Material

Our research and development team strives to equip industry with the broadest palette of trusty tools. Therefore, overcoming seemingly unpassable obstacles became almost an everyday routine. This time, we have decided to tackle the problem of exposure to the hazardous conditions which models might encounter during testing and their operation. Everything to further enhance the capabilities of 3D print.

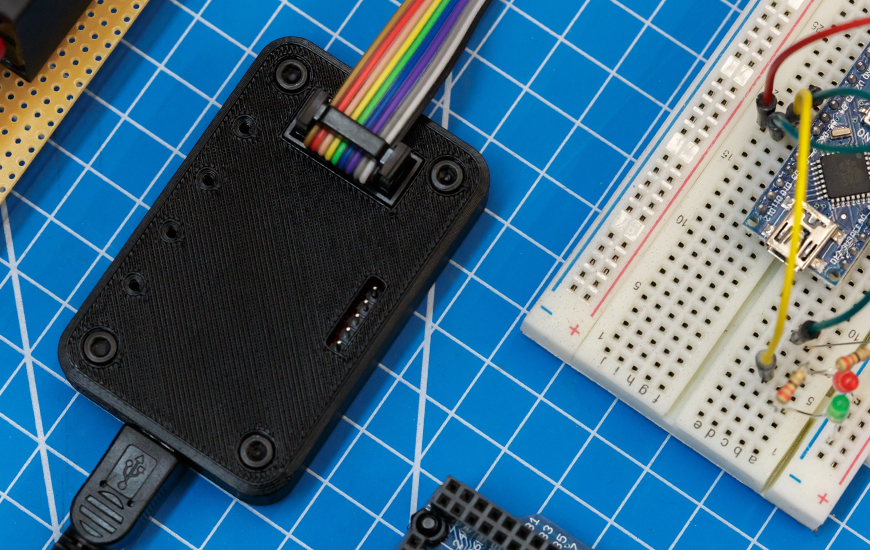

3D printed bus pirate casing

Without further ado, please welcome the newest addition to the Zortrax Ecosystem – Z-ESD! Material designed to withstand tough conditions of industrial applications. Its three key features make it perfect for prototyping parts and final components working in adverse environments.

Unique Features of Z-ESD

To start with, brand new Z-ESD gives you the unique advantage of electrostatic discharge protection. Wide resistivity range (from 104 to 109 ohm) allows it to eliminate the risk of electrostatic discharge and significantly reduce the damage of vulnerable components. For this reason, Z-ESD is the material to choose for electronic casings.

Its superior resistance to acids, salts and alkalis allows you to push the limits of rapid prototyping and test your models under previously unavailable conditions. Your prints will be always protected from threats posed by most commonly used chemical substances. Additionally, reduced shrinkage guarantees no warping and outstanding dimensional accuracy, even when printing large sized models. Be precise, be safe!

Thanks to its unique properties, Z-ESD provides reliable protection and quality required by industrial grade applications. Z-ESD comes in solid black colour and it’s available for Zortrax M200 and Zortrax M300 3D printers. Learn more about the new Z-ESD from Material Data Sheet. Please remember to update your Z-SUITE to version 1.9 before printing with Z-ESD. Happy testing!