VICTREX PAEK AM™ 200 vs. Z-PEEK: Which One is Better for You

Summary

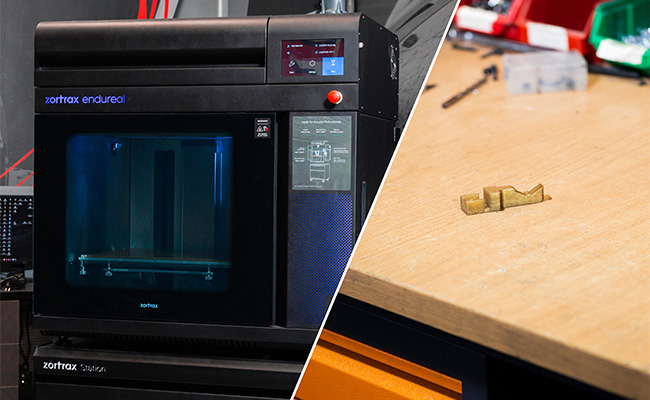

- VICTREX PAEK AM™ 200 and Z-PEEK are the strongest polymers available for the Zortrax Endureal 3D printer.

- Z-PEEK excels at the very top end of mechanical and thermal performance and has proven outgassing properties.

- VICTREX PAEK AM™ 200 offers exceptional Z axis strength and is a more versatile all-rounder option.

VICTREX PAEK AM™ 200 and Z-PEEK belong to the PAEK family of high-performance polymers and are in many ways similar. They both have superior mechanical strength, thermal and resistance, and are generally considered one of the strongest polymers ever made. Both are 3D printable, and both are calibrated for the Zortrax Endureal industrial 3D printer. There are differences that set those two amazing materials apart, though. Here’s everything you need to know about those differences.

Suitability for 3D Printing

Z-PEEK is a 3D printing filament made with standard poly ether ether ketone (PEEK), which has been on the market since the 1980s. This makes it great in all applications in which using extensively tested material with a proven track record is necessary.

VICTREX AM™ 200 is a new high-performance polymer compatible with the Zortrax Endureal 3D printer.

Z-PEEK is therefore be perfect for such advanced fields like space exploration or oil industry. But this long history also means that PEEK was originally intended for injection molding and CNC machining rather than 3D printing.

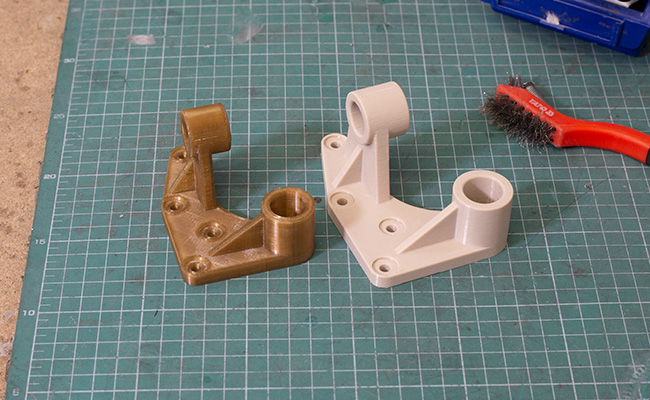

Brackets 3D printed with VICTREX AM™ 200 on the left and with Z-PEEK on the right.

VICTREX PAEK AM™ 200, on the other hand, is a PAEK polymer that Victrex engineers have designed for the 3D printing process from the ground up. All its key properties from viscosity to crystallization rate have been fine-tuned for extrusion-based additive manufacturing. This means that while the material lacks the extensive track record of PEEK, it enables 3D printing more isotropic and geometrically accurate parts.

Z-Axis Strength

Parts 3D printed on extrusion-based polymer 3D printers are always anisotropic. This anisotropy is caused by the very nature of FFF 3D printing. The 3D printing head deposits a molten polymer filament onto a build platform moving in a Z axis. The model is therefore built layer by layer and its mechanical strength is way higher when the force is applied against the layers than when it is applied along the layers. Z-axis is therefore always the weakest in the FFF 3D printed model. The degree of this anisotropy, however, is not always the same and varies greatly in different materials.

VICTREX AM™ 200 strength in Z axis exceeds 60% of strength measured in X and Y axes.

In models 3D printed with Z-PEEK, mechanical strength measured in the Z-axis is roughly 30% of the strength measured along the stronger X and Y axes. This is a consequence of relatively fast crystallization rate of PEEK. When the printing head deposits a layer of the model, the heat generated by the extruder module triggers the crystallization process in the material. This means that the subsequent layer of the polymer is applied on a partially crystallized filament which prevents strong interlayer bonds from forming.VICTREX AM™ 200, on the other hand, has very slow crystallization rate. The material does not crystalize that much in the same printing conditions which leaves just enough time to form strong interlayer bonds. This is why mechanical strength of parts 3D printed with VICTREX AM™ 200 printed on the Endureal 3D printer, measured in the Z-axis, can exceed 60% of the strength measured in the X and Y axes. The isotropy found in the VICTREX AM™ 200 models is therefore way higher.

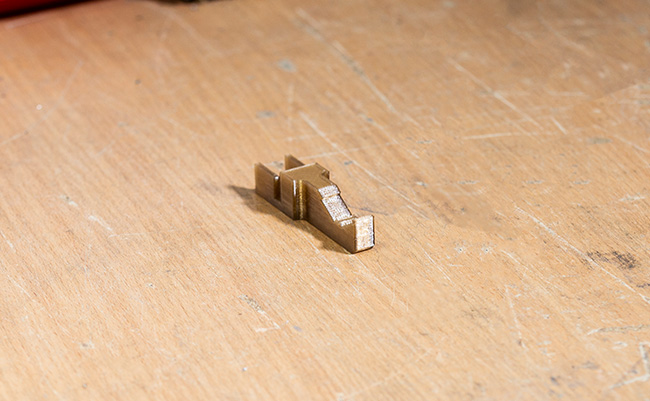

Dimensional Accuracy and Physical Properties

The difference in crystallization rate between Z-PEEK and VICTREX AM™ 200 matters also in dimensional accuracy and ability to print small details. Slow crystallizing AM™ 200 shrinks less when cooling down, which translates into higher dimensional accuracy. Small details, which can sometimes turn out crystallized due to overheating while printing with Z-PEEK, retain the same level of crystallization as the rest of the model when using VICTREX AM™ 200. The latter is therefore better for printing geometrically advanced, small parts.

VICTREX AM™ 200 works great in 3D printing precise parts with fine details.

Compared to VICTREX AM™ 200, Z-PEEK takes the lead when it comes to more standard metrics like XY tensile strength or melting temperature. Z-PEEK samples are up to 25% stronger in the XY direction and their melting point is as high as 346 °C, as opposed to 304 °C found in AM™ 200.

Z-PEEK also has outgassing properties certified by the European Space Agency which makes it a better fit for space applications, and working under vacuum conditions on Earth.

How to Choose Between PEEK and AM 200

There are multiple factors to take into account when choosing between the Z-PEEK and VICTREX AM™ 200. Z-PEEK is a bit more specialized material. It has outgassing certificates, it has better XY strength and higher melting point. This means that it will outmatch the AM 200 at the very top end of thermal and mechanical performance, provided that the model could be designed to account for high anisotropy.

Z-PEEK excels in applications where long proven track record of reliability is paramount while VICTREX AM™ 200 is a more versatile all-rounder option.

VICTREX AM™ 200, on the other hand, is a more versatile option of the two and simply checks more boxes at the same time. It has better chemical resistance than PEEK, offers better isotropy which comes in handy when it’s hard to predict the directions of forces acting on the 3D printed part and is way easier to print, offering better repeatability and dimensional accuracy. Overall, both Z-PEEK and VICTREX AM™ 200 are excellent materials, each in its own way.

Feel free to get in touch with our Sales Team on sales@zortrax.com and they will be glad to help you choose the right high-performance filament for your application.