How to Reduce Shrinkage by 3D Printing with Zortrax HEPA Cover

Zortrax HEPA Cover is a filtering device for Zortrax M200 Plus and Zortrax M200 3D printers that comprehensively tackles common issues with 3D printing ABS-based materials. It is a simple yet highly effective solution to shrinkage, unpleasant smells, and 3D printing emissions. Here’s how to use it to get more dimensionally accurate models.

Keeping The Temperature Stable

Zortrax HEPA Cover has two primary functions: filtering and keeping the temperature stable. HEPA and carbon filters installed in HEPA Cover take care of most of 3D printing emissions, including ultra fine particles and unpleasant odors. Temperature, in turn, is vital for shrinkage-free 3D printing. And that’s the key to dimensional accuracy.

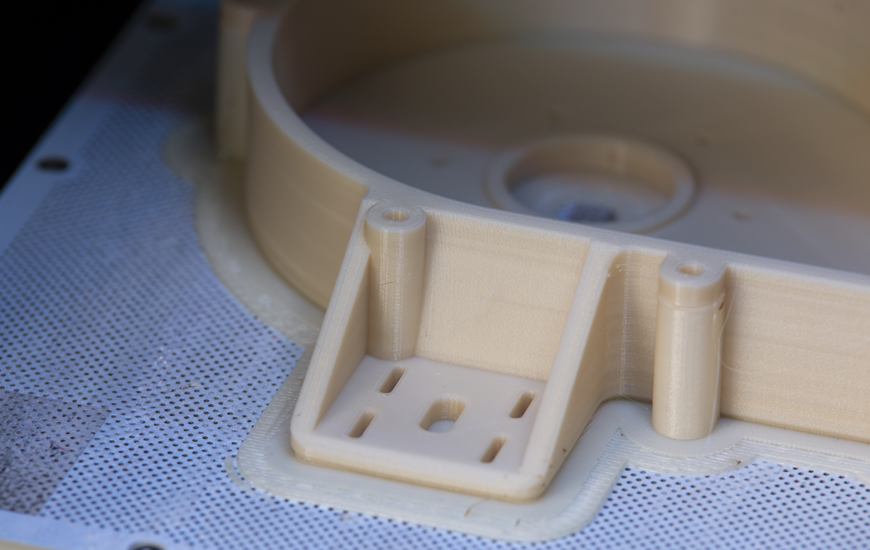

Turbine cover 3D printed with Z-ABS filament.

Stability of temperature inside the 3D printing chamber is extremely important when you are working with ABS-based thermoplastics. This kind of filaments is prone to shrinking and warping. Side covers protect against sudden changes in the room temperature, but Zortrax HEPA Cover takes it a step further. Together with the side covers, it creates optimal environment for 3D printing in stable temperature. Thus, Zortrax HEPA Cover effectively reduces models’ warping and shrinkage.

Advantages of using Zortrax HEPA Cover are as follows:

- equalization of the temperature inside the 3D printing chamber;

- stability of the temperature (with fan turned off or set to minimal or medium);

- acceleration of the chamber heating (with fan turned off or set to minimal);

- longer cooling process allowing for a proper compensation of tensions (with fan turned off or set to minimal).

The filtering device seals off the top part of the 3D printer. At the same time, it is designed not to impede the 3D printing process in any way. Quite contrary, it makes 3D printing even more reliable and problem-free. It all boils down to maintaining the proper temperature inside the printing chamber. The more stable it is, the better. Reduction of the temperature swings makes the shrinkage less likely to occur. The built-in fan can be manually adjusted to provide a greater control of the process. The fan set to minimal usually yields the best results, whereas adjusted to maximum it helps to lower the chamber’s average temperature (by roughly 4° C).

Optimal Temperature for 3D Printing with ABS

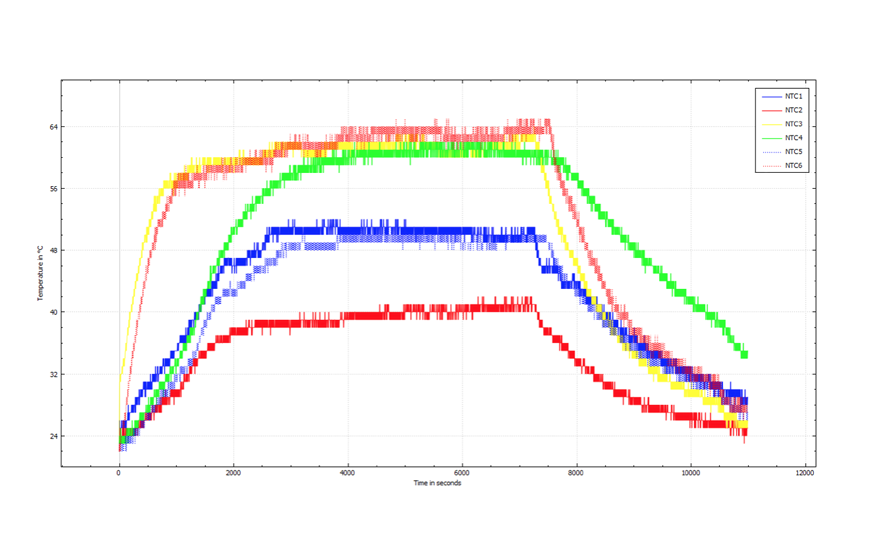

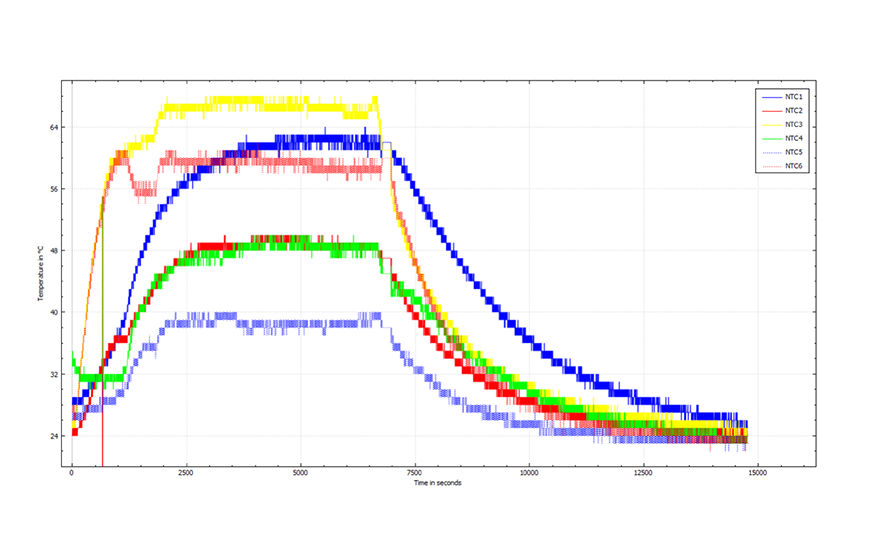

We have measured the temperatures during 3D printing with Z-PCABS and Z-ULTRAT. The readings were taken in three areas inside Zortrax M200 3D printer: near the extruder block, inside the chamber, and right above the platform. The results were compared with the same 3D printer, but without HEPA Cover.

Figure 1. Without Zortrax HEPA Cover: NTC1 – extruder block; NTC2 – chamber; NTC3 – platform.

With Zortrax HEPA Cover installed: NTC4 – extruder block; NTC5 – chamber; NTC6 – platform.

Figure 2. With Zortrax HEPA Cover installed: NTC1 – extruder block; NTC2 – chamber; NTC3 – platform.

Without Zortrax HEPA Cover: NTC4 – extruder block; NTC5 – chamber; NTC6 – platform.

On average, the temperatures were higher by 10° C. At the same time, Zortrax HEPA Cover is designed to avoid overheating of a model on the build platform. Furthermore, the conditions inside were significantly less prone to the ambient temperature fluctuation. The filtering device significantly reduced shrinkage and further improved the quality of 3D prints.

| Zortrax M200 | Without Zortrax HEPA Cover | With Zortrax HEPA Cover installed |

| Extruder block | 50° C | 60° C |

| Chamber | 40° C | 50° C |

| Build platform | 60° C | 64° C |

Zortrax HEPA Cover is compatible with Zortrax M200 Plus and Zortrax M200 3D printers. Installation of the filtering device is easy and requires no additional tools.

Order Zortrax HEPA Cover at Zortrax Online Store.