Grasping the Dream of a Miniature World

Welcome to the 3D printed world of Adam Mally! “There’s a child in all of us. You can feel it, when you look at the miniaturized models” – says the creator of AM Project, Wrocław-based design studio. The young team of 3D printing enthusiasts focuses on delivering stunning scale models for the architects and designers.

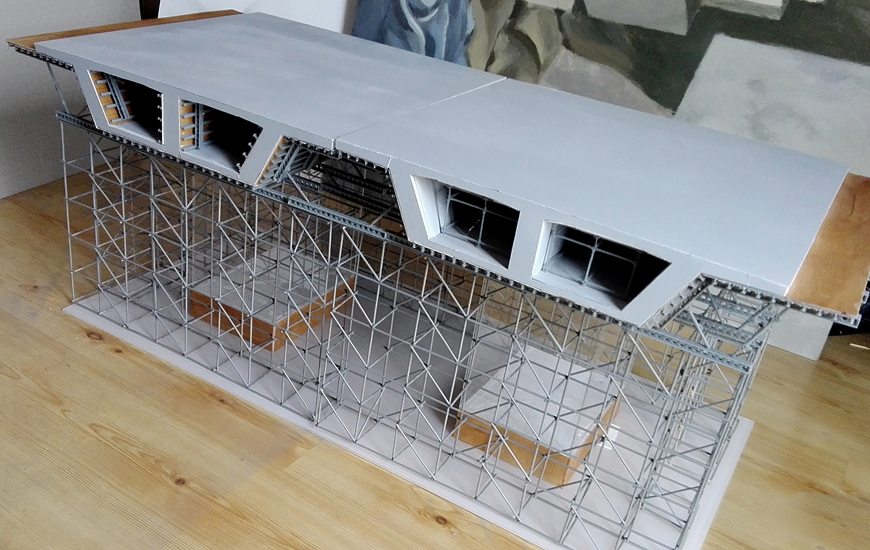

Detailed architectural mockup 3D printed by AM Project

A Dream to Build a Life on

Quote above perfectly summarize the Adam’s passion for 3D printing. Beginning with the architectural engineering studies at Wrocław University of Science and Technology, followed up by work at the architectural studios, lead Adam to the creation of AM Project. But, at the very start, there was a young guy wanting to fulfil his childhood dream. Luckily, during the studies, he was introduced to the 3D printing. From that moment, the path was clear.

Working in the Ecosystem

While browsing for an appropriate manufacturing solution for his design studio, Adam had only one dilemma: which brand of 3D printers should he choose. Traditional methods of mock-up’s creation compared to the LPD technology seemed insufficient in terms of capacities and speed. Although, the competition was tough, Zortrax came unmatched. The quality and precision offered by Zortrax Ecosystem was a dominant factor in the decision-making. Furthermore, price to value ratio and Polish roots sealed the deal. AM Project equipped with Zortrax M200 3D printer has begun to operate in 2015.

Z-HIPS provides architectural models with excellent smooth surfaces

AM Project

After finishing a couple of architectural mock-ups for Polish cities, AM Project seized the opportunity to showcase its miniature of bridge shuttering on a trade show in Dubai. The team is currently busy working on a size model of an aqua park. Apart from mock-ups for architects, AM Project is also helping designers to materialize and test their ideas. From the day one, use of the 3D printing was the studio’s advantageous asset to professional creators and engineers.

3D printed bridge shuttering

The Right Tools

Although, a number of clients, their specific needs and various methods of storing the complex architectural data might cause problems, integrated Zortrax Ecosystem is continuously facilitating work of AM Projects. As the team is using highly intuitive Z-SUITE software, compatibility issues became irrelevant. Furthermore, as long the file is provided in .stl format, Z-SUITE has no problems in converting it to a printable object. Working in the software is so easy, that Adam’s considers it a part of the team, doing a big chunk of the job. What they found right away helpful, was no need of mundane configuration and little to none maintenance required. Wide range of included functionalities and features provides AM Project with the right set of tools.

3D printed architectural mockup by AM Project

One Step Ahead

Even though the studio deals with a wide range of projects, the most spectacular ones are their architectural mock-ups. All of them are 3D printed using Z-HIPS material, which is perfect for large scaled models. Its significantly reduced warping shortens the time required for post-processing and ensures top-notch quality of the model. According to the client’s guidelines Z-HIPS might be left in its original colours or painted and safely sanded.

3D printed apartment building mockup

Unsurprisingly, scale models are considered the best way to present the idea of an architect. For they have what flat visualization lacks: local context, possibility of interaction and freedom of choosing the desired vantage point. Furthermore, to make them even more lifelike AM Project takes utmost care to provide close to reality settings for their models. Hence, all the handmade tiny details like trees, cars, bus stops and even pedestrians. They are often made with balsa, foam or cut on CNC machine. To make the illusion complete, they might even add lights to windows. Those stand-alone pieces of art draw attention of clients during trade shows and as showcase models at architect’s studios.

3D printed display mockup

Projecting the Future

Adam Mally cannot imagine his work without sturdy 3D printer. Zortrax M200 became an obligatory device in his office. Furthermore, he considers the current state as just a beginning of the new era of manufacturing and prototyping. That’s why he is always up to date with the latest news and developments in the 3D printing market. Proud and confident about his works, Adam laughs that he enjoys earing money on his childhood dream.