Will 3D Printing Cause a Revolution in the Car Spare Parts Industry?

The car spare parts industry is about to undergo a dramatic change as a result of the increase in popularity of 3D printing technology. It will be appreciated both by part manufacturers and by those who purchase the parts.

Manufacturing a spare part and delivering it to the customer is a complex process. What does it look like nowadays? First of all, you have to create the concept of the specific element, properly test the prototypes and send the final design to the factory. Then, you need to pack the finished parts, send them to a wholesale warehouse and thence to stores and repair shops. The goods pass through many middlemen before it eventually gets into the car, and as every middleman has to earn money, the final price is relatively high.

3D printing can lower it considerably. That’s because the technology brings about a simplification of the logistic process and removes most of the stages mentioned above. With a 3D printer, the final customers can print all the elements they need. There is essentially no transportation, just data transfer of the model and delivery of the filament, or the material used by the printer. Basically, the entire manufacturing process of the element takes place in one spot: where the 3D printer is located.

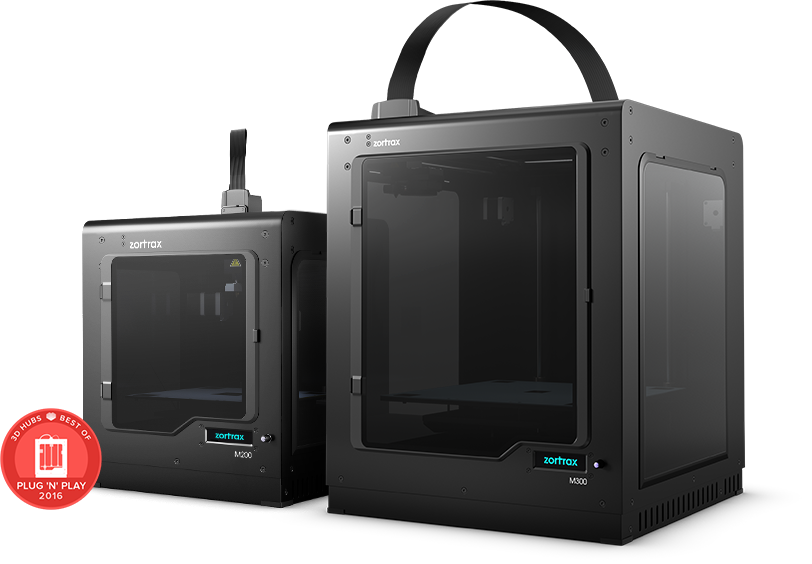

ZORTRAX M200 and ZORTRAX M300

Ever-ready Solution

Simplification of the production process will significantly shorten the time of waiting for a specific spare. Nowadays the time of having your car fixed becomes longer and longer as the workshop is waiting for parts: these need to be ordered and then delivered before repairs can commence. 3D printing will accelerate this process immensely. Every spare part will essentially be readily available, the waiting period will drop from days or weeks to minutes or hours—only as much as is needed to have the part 3D printed.

I have no doubt that widespread use of 3D printing will have a positive impact on the spare parts market. Everybody will be able to create alternative variations of parts, more durable than the standard ones. This will be possible because there will be a whole community of people with a passion conducting the work. It will be pretty much like with mobile enthusiasts on XDA forums who create faster OSs for smartphones and unlock the hidden potential of even the cheapest devices. Who knows, maybe the best community-created solutions will then be introduced by automotive corporations?

Reshaping the Spare Parts Market

It’s possible that thanks to 3D printing the price of spare parts will go down significantly. Only people with an actual passion will buy original parts. Everyone else will go for much cheaper and equally reliable (if not better!) substitutes. This is proven by the Bosch corporation. One of its factories decided to start using Zortrax M200 3D printers to create spare parts for machines used in the production line. As a result, the cost of a single spare part was reduced from €450 to €1. The difference is colossal.

There is no doubt that the popularity of 3D printing will keep increasing and that the technology will be used in more and more sectors of the economy. This is mainly due to the fact that the solution is inexpensive. A high quality, user-friendly 3D printer by a respected company, such as the Zortrax M200 3D printer, costs two thousand dollars at most. This shouldn’t be a prohibitive price even for a small company. And once 3D printing becomes commonplace, we’ll all appreciate its advantages. One of these is access to cheap spare parts which you won’t have to wait for. Spare parts which will be readily available in any store and repair shop.