3D Printing in Mass Customization. Meeting Customer & Market Requirements in Creating Customer Goods.

Maybe you are among the people, the vast majority of them, who asked about a particular product describe it as simply good or bad. Somehow they are right according to their own sense of correctness, taste or needs, but objectively they are far from delivering the right judgement. The thing here is that the key factor determining the purchase are our own preferences and the fact if the product fulfills our individual needs or not. Basing on this idea, we can divide the products into a personalized and non-personalized ones, the second of which should be left behind by market-conscious producers. Read this article to get to know what 3D printing actually gives you in case of creating customer goods.

Mind the Ergonomics

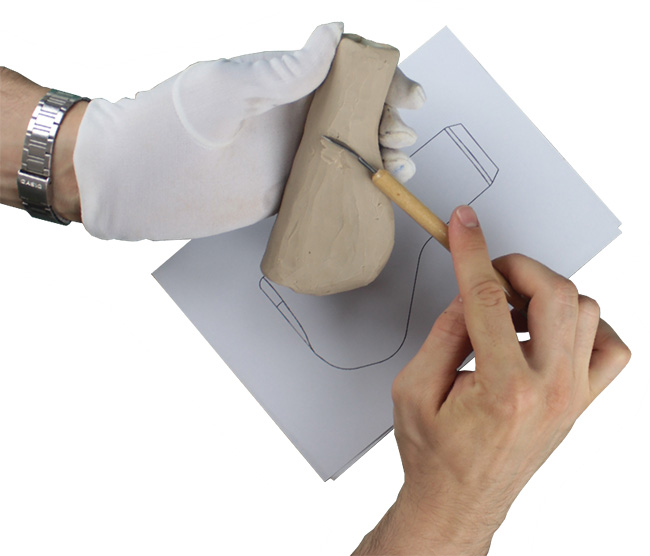

First of all, the product you create is to serve your customers well in many everyday situations, so the thing you need to consider is its ergonomics. That aspect should be thought over at the very production stage, as this is the perfect time for multiple trial and error testing and functionality evaluating. 3D printing simply allows feedback collecting and analyzing the defects really fast and without the need to outsource tasks which obviously take much time and sources. The value given by the 3D printer is the speed of the whole product cycle as the connections between the company and its outsourcers are shortened and so is the total time of the whole production.

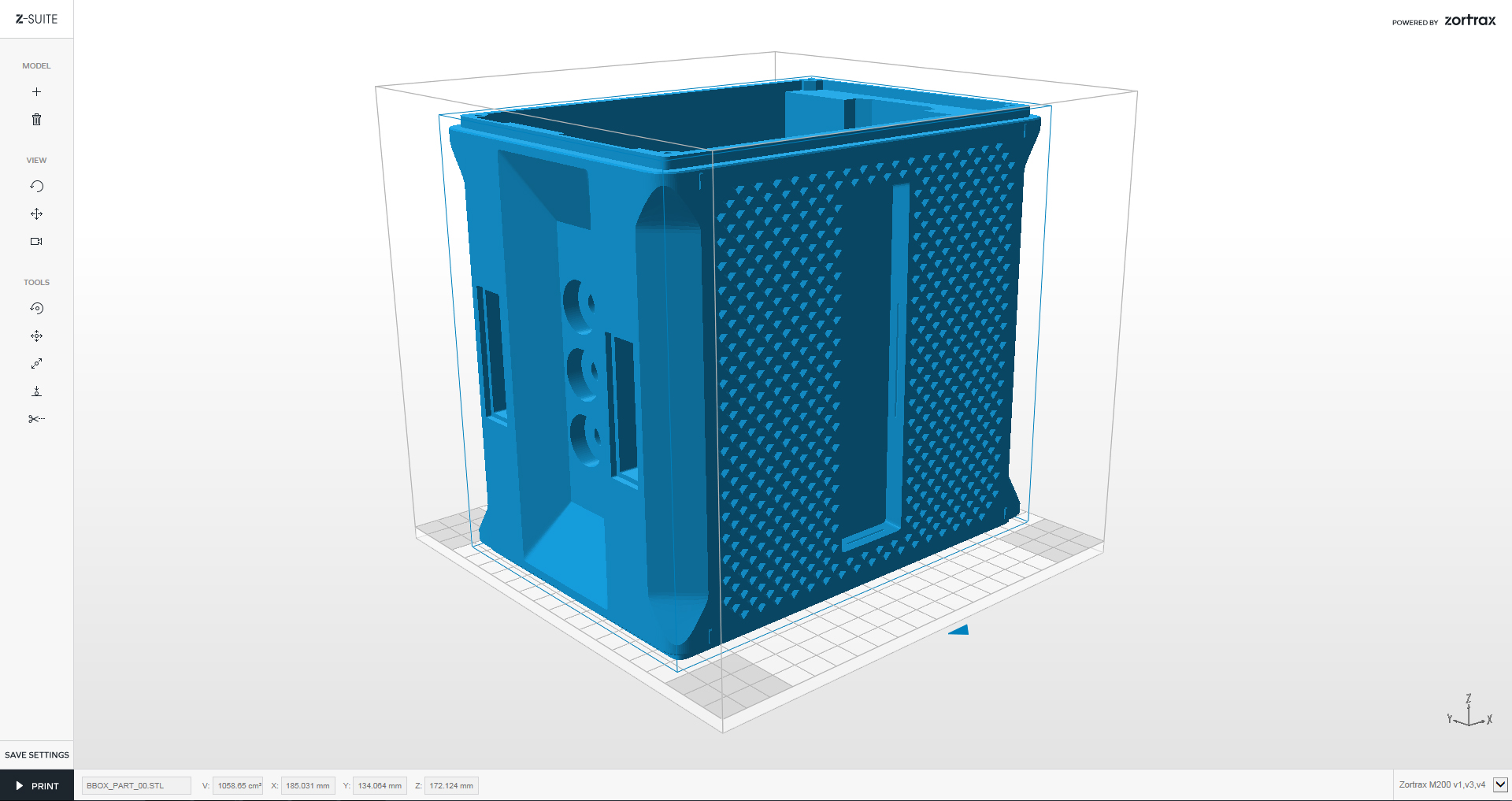

Incorporating a 3D printer gives you the ability to improve the ergonomics that in the case of a loudspeaker gets important as it is a device that should be suitable for the various conditions in which it will be used. Think about the end users and customize the piece according to the individual needs. Apply a mounting part to make hanging the device available or brush up on the shape to provide the piece will be easier to handle. Use Z-Suite slicing software to set the type of infill in the 3D printed model. By choosing the option light the Zortrax M200 3D printer will create a model which is really light and because of that is easy to transport (not to mention the economical advantages of saved filament).

Quality- Oriented Designs

The quality of a product that goes hand in hand with the perfectly suitable design is a rare thing. Especially, for those who don’t want to choose one by losing one another or waste their time on leafing through the buyer guides. Probably you are fed up with buying new stuff each year, as the old one gets broken or is not compatible with the newest technology. Get rid of short-lived technics and create your own alternative by 3D printing the loudspeaker cabinet and packing it with best parameters electronics. Having a 3D printer you can create stuff that lasts.

Choosing premium quality printing materials like Z-Ultrat or Z-Hips ensures resistance and durability. For the maximum satisfaction of the final look of your models, use various post-processing techniques that help you add the final touch to your prints by making their surface extra smooth and polished.

One-of-a-Kind Device

Freedom of choice and creating something unique is a craving of many as nowadays the market is packed up with lots of similar products available for masses. As the one-fits-all solution is no longer welcome, it gets obvious that product customization is the one that wins the nod thanks to providing the desired uniqueness.

Yet, creating something original is no longer a problem as thanks to the LPD technology incorporated by Zortrax printers, 3D printing the desired shape is within the reach. All the projects that grow as ideas in our heads can be actually turned to tangible objects by creating a design in CAD program, transporting it to a slicing program Z-Suite and 3D printing. A 3D printer is in fact a powerhorse that creates possibilities of product creation that were impossible and really expensive to obtain by traditional methods like e.g. injection molding, CNC machining or others (not to mention the costs of outsourcing if the tasks were delegated).

Constant Development

There are few products that don’t get old or out-of-date because of the changing clients’ preferences or global trends. The utility of customer goods depends on various, constantly changing factors, so entrepreneurs responsible for producing customer goods are pushed to seek solutions that will help them keep up-to-date with the present market. The fact is that the product needs to evolve to be present in buyers minds and to represents higher quality standards.

Developing our product due to the feedback collected from your clients is one thing. In the broader perspective by using a 3D printer you force your company to create new capabilities as the constant learning extends you knowledge concerning the product itself and also its reception, customers preferences and changing market trends.

To present you the capabilities of a 3D printer in the customer goods sector we 3D printed a loudspeaker that may as well serve as an end use part. The case study with free .stl files to download is right below.

Case Study

One of our designers needed a fully customized loudspeakers that would fit his flat and car interior, also his requirements concerning the quality of sound. Looking for a perfect model that would meet his needs was rather time-consuming task, so he decided to 3D print the loudspeaker himself. As the time previously devoted for research was saved, he could focus more on the design. He started from creating a model in a CAD program, then he imported it to the Z-Suite slicing software where he set all the parameters like type of infill, layer thickness, support angle and others. The program displayed the approximate printing time and the filament use.

The model was saved on an SD card and inserted to Zortrax 3D printer so the printing process could start. After printing all the parts the support was removed and the model was ready to be assembled.

The designer inserted all the electrical elements responsible for sound producing and the acoustic foam to provide good sound quality. All the printed elements were screwed together with an allen key so the model was finished.

After putting the parts together the loudspeaker was plugged to the tablet and the music was played to check the sound quality- it was perfect.

- The finished product is quite large and has an elegant, mat finish – that is why Z-HIPS was used to obtain this particular type of a surface and ensure durability of large-sized objects.

- The semi-transparent elements that covered the led lights were printed from Z-GLASS to enable the light to pass through the surface of the element.

- Z-ULTRAT was used as its properties make it perfect for producing end-use parts with excellent surface quality

The choice of high quality printing materials resulted in obtaining nice looking model without the need for post-processing, however if such need appears according to anyone’s individual preferences – manuals covering various post-processing techniques can be found on our Support Center.

The chart concerning the basic data regarding the process is presented below.

| Filament Usage | Printing Time | Type of Infill | Color of Material | Type of Material | Layer Thickness | Estimated Cost | |

| Part 1 | 466 g | 63 h 32 m | Light | Black | Z-HIPS | 0,14 mm | 29.09$ |

| Part 2 | 52 g | 7 h 38 m | Light | BLACK | Z-HIPS | 0,14 mm | 3.22$ |

| Part 3 | 271 g | 35 h 10 m | Light | BLACK | Z-HIPS | 0,14 mm | 16.92$ |

| Part 4 | 43 g | 4 h 33 m | Light | GREY | Z-HIPS | 0,14 mm | 2.68$ |

| Part 5 | 1 g | 4m | Mesh | NATURAL TRANSPARENT | Z-GLASS | 0,14 mm | 0.04$ |

| Part 6 | 23 g | 2 h 3 m | Light | YELLOW | Z-ULTRAT | 0,14 mm | 1.47$ |

| Part 7 | 18g | 2 h 5 m | Light | YELLOW | Z-ULTRAT | 0,14 mm | 1.12$ |

| Part 8 | 4 g | 0 h 29 m | Light | GREY | Z-HIPS | 0,14 mm | 0.24$ |

| Total | 878 g | 115 h 34 m | – | – | – | – | 54.78$ |

List of Materials:

- set of screws

- allen key

- acoustic foam

- Zortrax M200 3D printer

- filaments from Z-Filament Series

- electronics taken from Creative Giga Works T40

The whole process was based on LPD technology – the liquid filament was extruded layer after layer to create a solid model together with support material. The printing speed varies according to the chosen layer thickness and the type of infill, by selecting high layer thickness and light infill we can speed up the process considerably. LPD technology allows to create good quality models fast and cost-effectively by using materials that are durable and can be easily post-processed. LPD is a fully automated technology enabling in-house production, which makes this technique perfect for prototyping and iteration.

All the files needed to 3D print the loudspeaker are available here. Leave your personal data to download the files.