How 3D Printers Support R&D Every Day

3D printing technology brings about a profound shift in how certain departments of certain companies operate. For some, the result is savings in the hundreds of thousands every year. There are still many fields waiting to be revolutionized by 3D printers such as the Zortrax M200. 3D printing has become an invaluable support for R&D departments in the tooling industry.

3D printing is often associated with hobby projects and with prototyping for the purpose of industrial design. In fact, the technology is also used in industry at various stages, from project through production. R&D departments are fond of it as well. 3D printing is becoming increasingly widespread in industry, including the tooling industry.

Reshaping the Industry

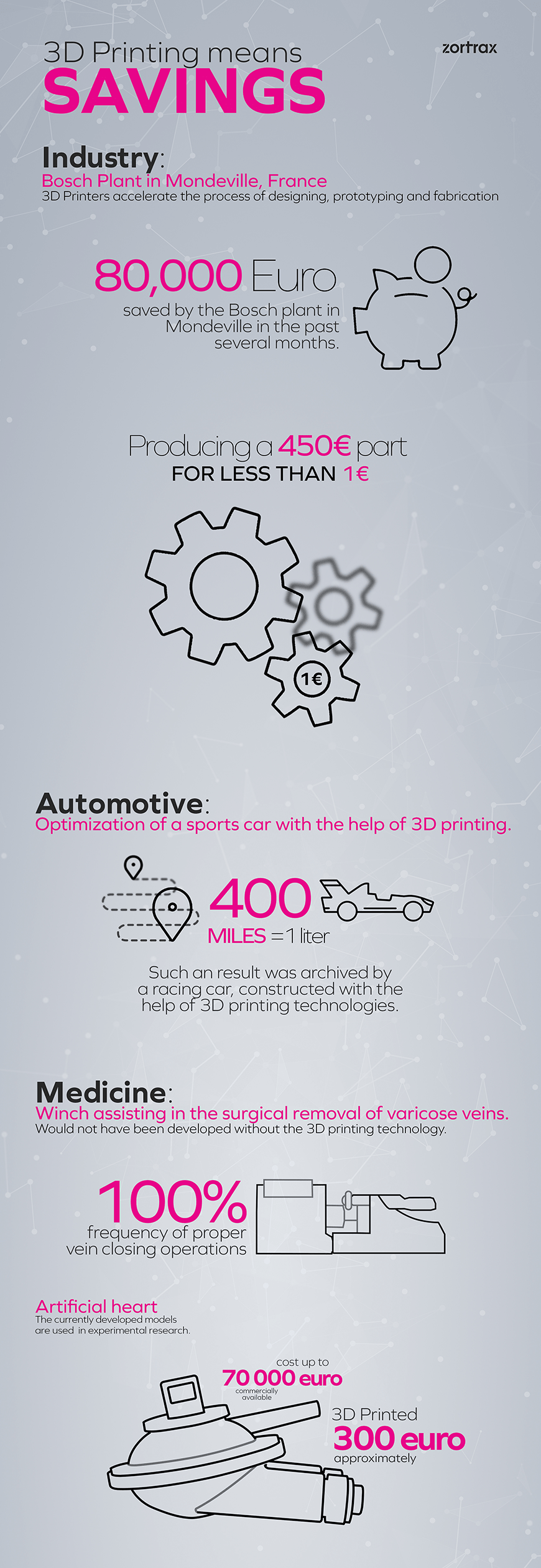

One of the most recent and most interesting examples of this kind of application of 3D printing comes from Bosch. The French branch of this corporation, which manufactures tools and components for the automotive industry, has being using Polish Zortrax 3D printers since 2015. These printers are used at various stages of the factory’s operations: they 3D print out spare parts for machines but they also help create new components and additional parts. According to company representatives, savings of at least 80 thousand euros have been accrued since the introduction of Zortrax 3D printers.

In the Bosch plant in Mondeville, France, Zortrax 3D printers work 24/7. They create spare parts which instead of costing 450 euros cost 1 euro. And they create completely new solutions for the company to make its operations easier. One of the devices developed by Bosch engineers are handles for wires which protect them and make them easier to be removed. New tools are also being developed, suited to the specific needs of specific departments thanks to the possibilities of 3D printing. This is the only existing method that makes it possible to inexpensively and quickly prepare an item which your employee needs on the spot.

R&D of Tomorrow

The R&D departments focus both on perfecting the products as well as developing faster and more efficient methods of production. 3D printing makes their job easier through giving them the possibility of rapid experimenting and conducting tests without large investments. The R&D department can work on a trial-and-error basis without risking time and money. If the engineer stumbles upon an idea for a tool which could potentially accelerate work, he or she will have it ready in a few hours for testing. Making adjustments is easy, as is duplicating the tool itself. 3D printing puts professional, safe, and durable tools in place of makeshift solutions.

Bosch representatives are right when they say that companies in the industry which don’t utilize 3D printing are missing out on a lot. Thanks to solutions such as the Zortrax M200 3D printer such devices have become easily available both in terms of prices as well as in terms of technicality. The potential possibilities are endless, especially in R&D. 3D printing is freedom of creation, of discovery, of exploring new solutions are perfecting those we already have. At the same time, users point out that the devices pay for themselves through significant savings. 3D printing technology also saves you time by letting you create various items on your own.

3D printing is part of the new industrial revolution. Together with advanced robotics, telecommuting and globalization, it gives you immense possibilities. Possibilities limited only by your employees’ will and vision. 3D printers by companies such as Zortrax are tools for creative people—not artists, but engineers. On the other hand, operating the device does not require specific skills or qualification. 3D printed models essentially don’t require any input on behalf of the operator which lets 3D printing be conducted 24/7.