Why Using 3D Printers in Agile Manufacturing Drives You to Fast Success

The Agile methodology has proven useful in software development and has become a common standard. It’s also believed to be the foundation of the rapid progress in the software industry in recent years. Agile development eliminates the drawbacks of cascade control systems and significantly shortens the time necessary to complete the product. No wonder that the methodology has spread beyond software development. Combined with the widespread use of 3D printers, it yields spectacular results.

Agile Methodology as a Remedy for the Tempo of the World’s Rapid Evolution

The key to the successful application of Agile methodology lies in shortening the way of the product from the project phase to the manufacturing phase, so as to be able to immediately react to the changing needs of the client, the market situation and other factors. Dividing the project into phases makes it possible to improve it on the fly thanks to periodic retrospectives. This is all perfectly fine when it comes to software, where changes can be introduced as you go. Unfortunately, in industrial manufacturing things are not so simple.

Challenges for Agile in the Manufacturing Process

Manufacturing physical items used to require a lengthy technological process which stretched the timespan of the project. The planning phase was critically important due to the fact that modifications in the implementation phase meant prohibitive costs and delays. As a result, the Agile methodology could only be used in specific cases.

3D Printing is Agile Manufacturing’s Key to Success

Thanks to the use of 3D printers in the manufacturing process costs are significantly reduced and the possibilities of introducing changes into the project while also reducing the time needed to implement them. Manufacturing no longer requires preparing expensive forms which you then have to use for a long time in order to minimize costs.

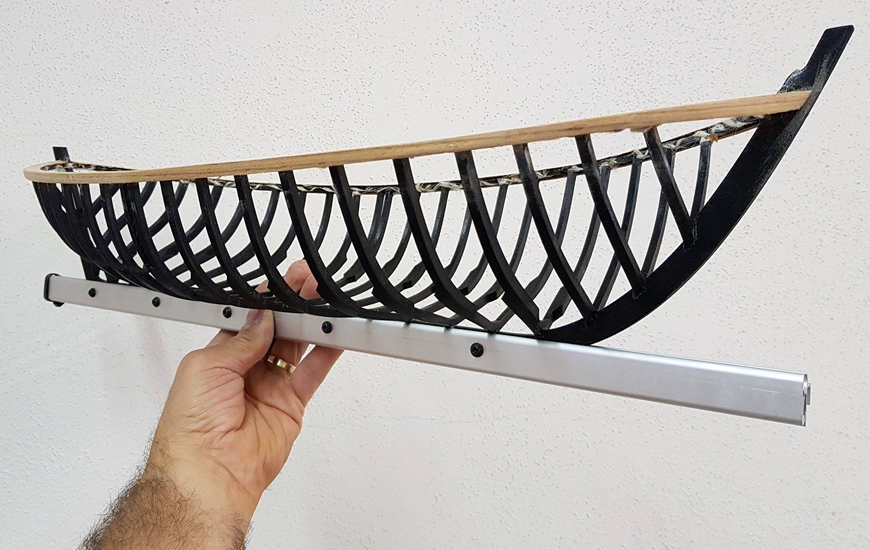

It’s almost as if 3D printers were tailored to methodologies such as Agile Manufacturing. The time needed to modify the project has been reduced to an absolute minimum. As a result, the benefits of using 3D printers are visible as early as during the project phase. You can create a number of prototypes and modify them according to the results of your research or feedback from testing. With Zortrax M200 and M300 3D printers, thanks to their Z-SUITE software, you can introduce changes into a project within minutes.

As a result, you constantly improve your product, making it better with every iteration. This is a perfect display of the idea of Agile Manufacturing, or manufacturing which is able to instantaneously react to any factors.

Reaction Time is Key

Time limits constraining any modifications to the project are what makes 3D printers such a good tool in Agile Manufacturing. Time is one of the main cost-inducing factors. Moreover, in some cases the time needed to implement the product may be what ultimately decides its success or failure. The ability to immediately improve every subsequent iteration of the product—which is possible thanks to 3D printing—affords immense possibilities. You can create new prototypes in a fraction of the time you’d spend with traditional methods. You can also change the finished product, improve it almost without any added costs to the manufacturing process.

Modern 3D printers, such as the Zortrax M200 and M300, are perfect for implementing the Agile Manufacturing methodology thanks to their versatility. They will let you take advantage of all the benefits of the methodology while keeping costs low. When you add the acceleration of the process of design and production, you can achieve success a lot faster.