The World of Micro Models – 3D Printing Applied to the Jewelry Design

As we mentioned it in the last blogpost we put much effort to support our users at many levels, to make them feel confident while using any of the element from the Zortrax ecosystem and obtain satisfactory results. However, sometimes we don’t have to as our users keep on amaze us with their models and applications for 3D printing. This time we would like to write a few words about Ronny Raimondi who mastered the 3D printing technology to such level, that we couldn’t do nothing but share it with you. We are happy that we can start this year with lots of incredible models 3D printed on Zortrax M200 and give you a tiny-sized, but solid piece of inspiration.

Precise and Precious

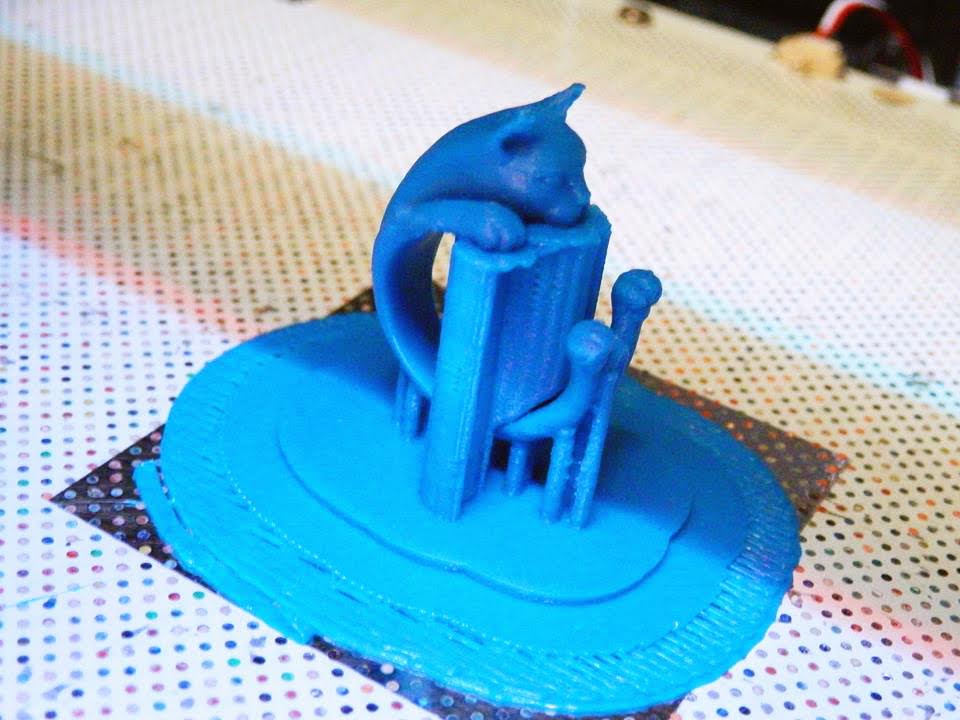

It’s definitely great to know, that we have such talented users as Ronny Raimondi, but seeing them utilizing our 3D printers at their everyday work is a cool thing too. Our Italian-based user is a jewelry designer who works for Silver 3000 srl company where he incorporates Zortrax M200 to create prototypes of rings and other decorative elements, most of them having the size of a coin or even smaller, like for example the rabbit presented below having the size of 6 mm diameter. As we know, jewelry makers are people who put great attention to details, precision and the quality as the objects they work on are have purely decorative function and are usually made of expensive materials like gold or silver. However, within the time and development of the new technologies as additive manufacturing, the process of developing a product, even in the jewelry industry became much faster. Apart from the fact that creating the visualization of the product is now available on the more advanced level thanks to various modeling programs like Rhinoceros, Matrix or others used to create the CAD model, the ability to test and evaluate on the prototype is much more accessible and cheaper. Basically, on the example of Ronny’s models we can see that Zortrax M200 wich is an LPD technology based 3D printer could be successfully used to create prototypes of extra small objects like fine jewelry.

Pushing the Limit

Following on this idea, the examples provided by Raimondi, apart from standing for their own quality, simply show that dimensional accuracy and precision are obtainable at the reasonable price, as M200 has got unique in its segment price-value relation. Not to mention the fact that having similar results on other 3D printers from the same, or even higher price level would be difficult or impossible. Having asked Ronny about the reason of choosing this particular printer, the designer responded: “I have chosen to print with your Zortrax ’cause after extensive research and testing I found and the best FDM printer with high precision, robust, with components of quality”. Being aware of the fact that not everyone is as experienced in 3D printing as Ronny Raimondi, on our Zortrax Support Center we provided a series of manuals and tips concerning 3D printing small objects and other.

Affordable Technology

Probably most of you are familiar with the fact that currently on the market we already have 3D printers using liquid metals like gold or silver as printing material to create end- use products. There are also websites where users can make up with their own designs and order a fully customized pieces of jewellery. That’s a fact, however using a LPD 3D printer shows its full advantages at the very design and evaluation stages. Mainly, because of the fact that in Zortrax 3D printer the printing materials are plastics characterized by various properties and surface structure, so utilizing them will be obviously much cheaper than the metals, not to mention the high prices of such 3d printers. What is really essential here us the ability to reshape, redesign and add multiple remarks to the product as in the case of Zortrax M200 it is affordable and fast. Each time we 3D print a jewellery piece we can try it on and see if it meets our needs, and if not just redesign our project and make another version of the model.

From Conception to a Finished Product

When it comes to the final look of the 3D printed models, their quality can undergo further improvements as Zortrax printing materials are suitable for various post-processing techniques. The Italian designer told us that in his company they use more advanced post processing techniques including also metalization which is a technique based on coating the object with a thin layer of metal to make its surface more shiny, smooth, resistant and to make the prototype more similar to the end-use product. As we can see on the attached pictures, the metalized 3D prints can fully reflect the look of the brass jewellery pieces.

Being Passionate Pays off

Indeed, looking at Ronny’s works we can see that possessing a talent and having the right tools to express it make a powerful combo. In fact the designers of various industries can find their own application for 3D printing, as Ronny Raimondi claims that by 3D printing he can “… carry out the plans of others and also my, we are in a new industrial revolution where also the new materials will make the difference ..”. Bearing this in mind we can assume that the additive manufacturing technology is gaining its momentum. In the future we may have even more opportunities to apply 3D printing in various industries and streamline our business by using up-to–the-minute, yet reliable and affording solutions provided by Zortrax.