3D Printing that Supports Industrial Design – School of Form

Great design starts with ideas of talented people, creative minds and creators with a huge aesthetics sense, those who want to sneak a little art to the everyday use objects. However, the way from the conception to a finished project can be sometimes a rocky one, especially without the proper tools that make the whole process of creation fast and efficient.

The Identity of ID

Industrial design is in fact a vast and dynamic branch that focuses on preparing products that are to be further utilized in the mass production. ID is not merely about functionality and utility, as these two belong mostly to the concerns of engineers, however incorporating the additive manufacturing technology allows limitless utility and ergonomic testing in a commercially-viable way. Thus it can be assumed that 3D printing can facilitate evaluating the model and testing it under various angles and by that extending the spectrum of features non-related to the product look only.

Polish Design Comes First – School of Form

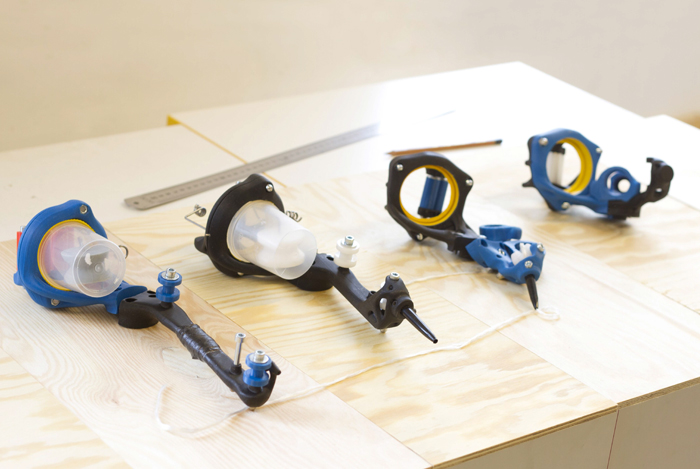

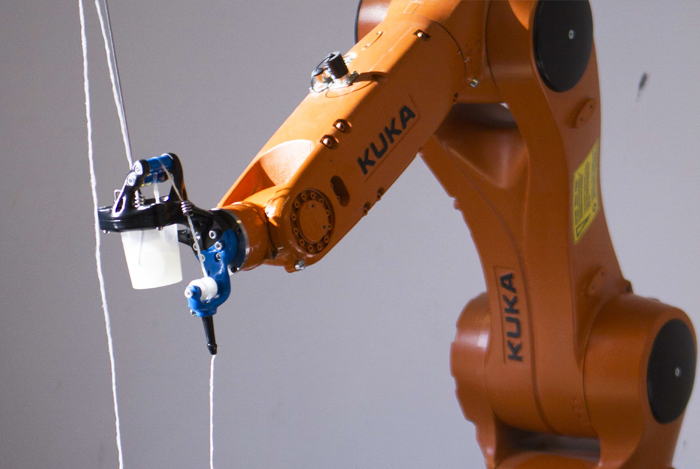

A role model of the educational unit that successfully utilizes 3D printing technology and represents the Polish know-how combined with innovative approach and talent is Poznań-based School of Form. This division of the University of Social Sciences and Humanities gathers the most creative young people and allows them to develop their ideas with the help of innovative business tools like Zortrax M200 3D printers. Equipped with the solid knowledge concerning the designing, culture and philosophy, the students can get into the practical side of creating the product using the latest technology. We have to admit that they do it pretty well and easily adjust the possibilities given by 3D printing to their current projects. What’s the most interesting and creative about the utility of Zortrax devices in the School of Form is the fact that they are not only used to create the designs, as 3D printed parts also serve as the components of the tools used to make prototypes. In the film presented below we can see how handlings 3D printed on Zortrax M200 allowed to change the KUKA robot into a multifunctional machine. Those of you who would like to 3D print their own KUKA inspired robotic arm can find more in one of our previous posts.

Thanks to the 3D printers the students can have more freedom in designing and testing their products which additionally enhance their learning possibilities as they can get to know the properties of materials and draw some useful conclusions about the mistakes. Apart from this, they also learned how to prepare files in the various modeling programs to create the designs with proper dimensions and suitable to be 3D printed.

From Draft to an Icon

Design matters as it simply determines the lifespan of a product. Great design lasts and within time it may eventually become iconic. Some of you may consider plastic as not the best material to create designer products, but in fact thanks to the great quality and variety of Zortrax materials it may be well used in prototyping and even creating end-use products. First of all, the form matters. With Zortrax M200 3D printers the students from the School of Form could create various models ranging from really small like flash drives to even bigger ones like handlings of KUKA robots. Concerning the area where the product is to be applied, users could choose a particular type of Zortrax material and decide if they want to 3D print for example large furniture pieces of Z-HIPS, translucent, glass-like models from Z-GLASS or ultra strong and resistant pieces from Z-PCABS and more. When it comes to the colors which, as we know, can sometimes indicate the target users of the product or stress its character Zortrax users can spread their wings. Having the opportunity to choose from 15 different shades of Z-ULTRAT, not to mention the rest of the materials, everyone can make their models colorful, unique and what’s even more important, fully customized.

Printing Makes Perfect

Great design doesn’t happen by accident, in fact it is a long and repetitive process that may be significantly accelerated by the additive manufacturing. In today’s market full of competition and product with similar prize and purpose the details, innovativeness and timeless design are the things that matter and help to influence the purchasing decision and win users loyalty. But before our designs become real tangible products and reach store shelves we have to put a lot of effort to make them look like million dollars. As it was presented in the article and the featuring pictures talent and creativity with the help of the help of the present technology of 3D printing can move your work to the next level.