Z-SUITE 3.5. Great Improvement Full of New Functionalities

Summary

- Z-SUITE 3.5 the newest update for our slicing software is available.

- The program gains new functionalities improving models' durability, accuracy, and overall quality.

- The Outer walls options is one of the main new features which allows users to control the number of models' contours.

The latest update of our 3D printing software – Z-SUITE 3.5 is now released and available for everyone. The slicer has been improved with multiple new functionalities that let you be even more efficient im preparing your models for 3D printing. One of the key new features is the Outer walls option which allows improving mechanical durability and dimensional accuracy of the 3D printed parts. You can now boost your prints’s strength and precision by setting the number of printed contours. Z-SUITE 3.5 also brings major changes and improvements to parameters like Infill and Seam, and the prints’ and enhances quality of your 3D printed parts. Below you can learn more about why Z-SUITE 3.5 is the most powerful 3D printing software we have ever created.

The following Zortrax 3D printers are fully supported in Z-SUITE 3.5: Zortrax M200 Plus, Zortrax M300 Plus, Zortrax M300 Dual, Zortrax Inkspire 2 and Zortrax Endureal.

Multiple Contours Feature Brings Great Benefits

While working on the next update of our software, we focused on implementing features that would improve the durability and accuracy of the 3D printed parts. The new option – Outer walls – grants you the ability to manipulate the number of the outermost walls in your models, that is 3D print with multiple contours. This is what you can obtain when using the feature:

Increased Durability

The Outer walls option allows you to easily reinforce your 3D models. If you aim for sufficient durability in your final print, simply increase the number of outer walls in Z-SUITE. Tweaking this parameter is especially useful for models with openings or models intended for any kind of post-processing, mechanical or chemical. With more outer walls, you make sure you won’t damage your print by, for example, assembling nuts or screws in it. Also, a higher number of outer walls can bring better post-processing effects during chemical smoothing.

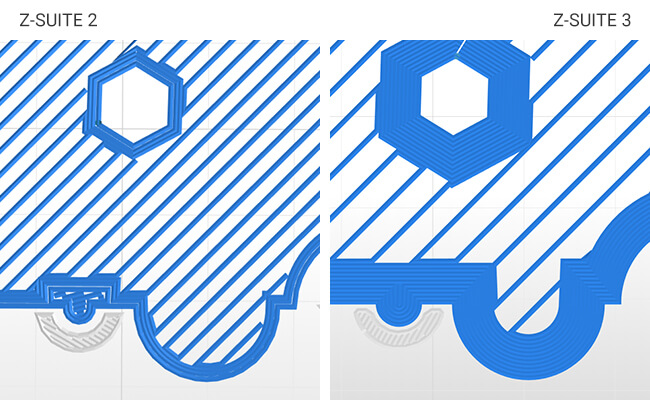

The graphic shows an increased number of outer walls in a model prepared in Z-SUITE 3.5 (on the right).

Improved Dimensional Accuracy

Using the multiple contours feature will also improve the precision of your final parts. This option reduces differences in dimensional accuracy as the number of contours is constant from the first to the last printed layer. As a result, you’ll notice better quality of overhanging areas and less deformation. If you want to assemble your 3D model from separate parts, select a higher number of outer walls. Your prints will simply represent the design more precisely and fit perfectly into one another.

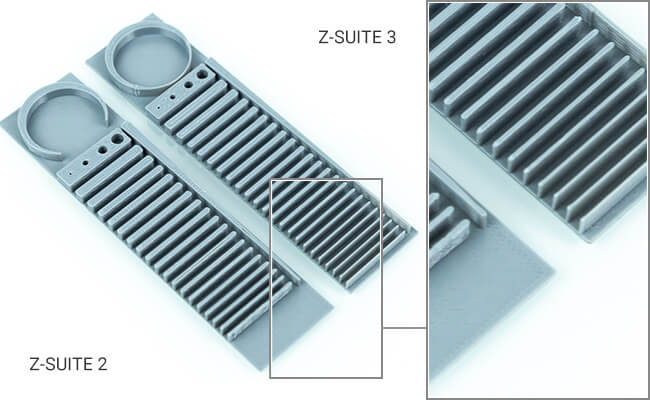

The photo shows a comparison of the quality of overhangs in models 3D printed in the single-extrusion mode.

Additionally, the feature can be used when printing in the Shell mode to counteract the brittleness typical for the prints made in this method.

New Infill Patterns For Improved Strength

Facts Z-SUITE 3.5 brings the possibility to increase the number of outer walls The new functionality increases the durability and precision of 3D prints Other significant changes include: three new Infill patterns

The newly released Z-SUITE version comes with three new Infill patterns which you’ll find in the Normal and Advanced sections of the Print settings step. You now have even more ways to control the level of your parts’ strength and weight. Here are the details of the new patterns:

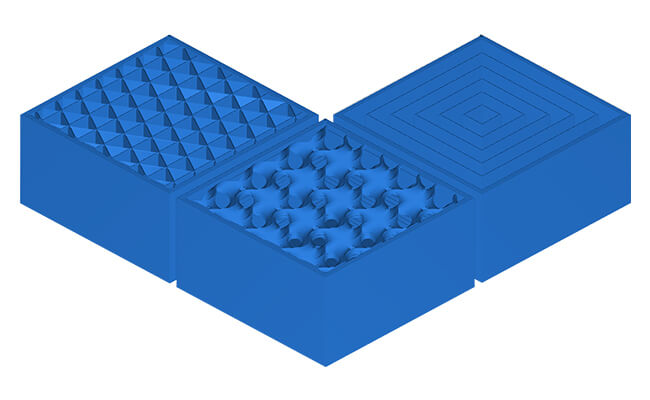

- Triangular (Patt. 5) – this infill type is recommended for models which have to show better compression strength to forces applied perpendicularly, such as joints and hinges.

- Gyroid (Patt. 4) – this infill type is designed for models having to withstand forces applied along all three axes. The shape of this pattern changes in all three directions, and as a result, provides high overall strength to models, such as functional prototypes and end-use parts. The gyroid infill can be successfully used with lower infill density levels, which in turn can help you reduce material consumption.

- Concentric (Patt. 6) – this infill type is useful for models with many narrow and small elements, as well as parts printed out of transparent and flexible filaments. This pattern reflects the model’s outer walls and evenly supports the top layers. It is also recommended to be used with high infill density values. The Concentric pattern has also been introduced for the Solid infill type to further improve the durability of parts printed in this mode.

3D printed cubes showing new infill patterns: Triangular, Gyroid, Concentric (from left to right).

Dynamic Infill for Thin Walls

Another feature worth mentioning relates to very thin walls and small gaps between outer and inner walls in models. We’ve improved the method of generating the infill for such areas and they now have a single-path infill which is printed with variable material feeding. Z-SUITE 3.5 will dynamically adjust the amount of filament to the width of a thin wall or a gap. As a result, you’ll be able to print stronger parts with less artifacts, such as holes, in the top or bottom surfaces.

The photo shows a 3D printed part prepared in Z-SUITE 3.0 (on the right). You can see how a small gap between walls has been filled with one path.

More Control with the New Seam Types

Facts Z-SUITE 3.5 adjusts the amount of filament to the size of thin walls and small gaps Users can now control the location of the Seam in their prints It is now possible to make the Seam less visible

The next noteworthy changes you’ll see in the update relate to the Seam settings. First of all, we’ve added the Avoid overhangs checkbox which improves the quality of slanted surfaces. Once you check this option, the seam will not appear on overhanging layers and will be placed elsewhere on the model.

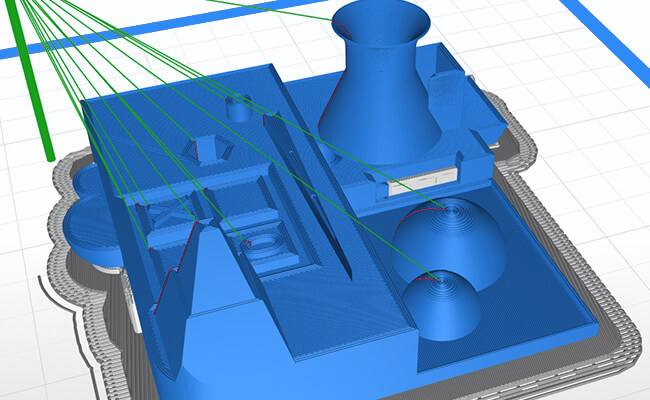

Next, there are new Seam modes which allow you to choose the location of the seam with greater control:

- User specified – you can indicate a specific point, represented as a green bar, within the platform by choosing its coordinates in the X and Y axes and the seam will be generated as closely to the selected point as possible. This type of seam can be very useful for any exhibition models or functional parts. You can place the seam at the rear of the object,

- Inner corner – once you select this option, the slicer will “hide” the seam in the inner corners in the model’s geometry.

- Sharpest corner – similarly to the previous type, this option will make the seam less visible by placing it on the sharpest outer corners on the model.

A preview of User specified seam settings The green bar represents the reference point within the platform.

With those three new options, you can fully control the way of generating the seam and achieve the desired aesthetics of your printed parts. On that note, we’ve also improved the quality of other key areas in the 3D printed parts. The slanted and top surfaces, as well as the blocks of supports are now smoother and have less irregularities with fewer little holes and other artifacts.

Moreover, there’s a new checkbox Print Too Thin Walls in the Thin Walls section. In the previous Z-SUITE versions, walls thinner than approximately 0.4 mm were not sliced and printed. Such elements were not included in the .zcodex preview, which was a sign to redesign the project. Now, any wall with measurements in the range of 0.4 – 0.8 mm will be printed with a single path to achieve the best quality and accuracy possible. The walls with dimensions smaller than the given range will be thickened to approximately 0.3 mm.

The photo shows a 3D printed part prepared in Z-SUITE 3.0 (on the right). All thin walls were properly printed with a single path.

In addition to newly created material profiles for the M Series Plus, further materials are added to the M300 Dual printer, including 316L and 17-4PH filaments for 3D printing metal parts. The Endureal printer also receives new material profiles not only from the high-temp segment but also basic ones such as PLA and the popular PA6 and PCABS.

We highly encourage you to try all new features in your 3D printing work and let us know what you think. Feel free to report any issue you’ll find – use the Report a bug option in the Help section. Also, if you feel something is missing and should be available in the final version, just let us know through the Feature request option. We will certainly consider every suggestion.

The full changelog is available in the Downloads section at the Zortrax Support Center.