Zortrax 3D Printed Industrial Prototypes

Zortrax presents a new quality of prototyping to industry – 3D printed MOCKUP, INDUSTRIAL ROBOTS, MIDI CONTROLLER and a SKULL. See how high-accurate and efficient prototyping is changing business.

Zortrax® technologists have prepared models focused on demands imposed by industry of machine prototyping, architecture, design and education. So how does exactly a good-prized, efficient and accurate 3D printer bring changes to those industries?

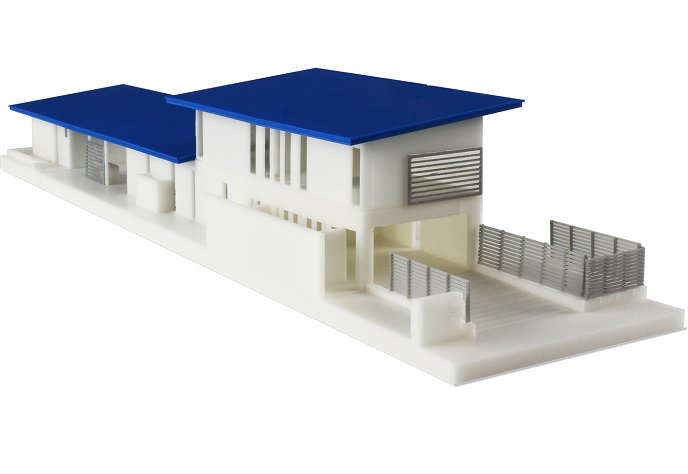

ZORTRAX® PROTOTYPES FOR ARCHITECTURE

For architecture, the answer is simple. Why prepare time-consuming, old-fashioned mockups within days, if you can 3D print it within hours? Modern architecture should incorporate modern technology. 3D printing can save time and money. It allows to prepare ready-to-show mockups, colorful and detailed, directly from CAD data.

Now architects can detect the potential errors early and work on improvements. Refining the design concept is a time-consuming process, so fine details, smooth surfaces and printing time is crucial.

Zortrax Mockup

The architectural model is 3D printed on Zortrax M200® from Z-ULTRAT® and Z-ABS® filaments with layer thickness of 0,14mm and 0.91lbs (442g) filament usage. Printing time for this prototype is 54h 13min.

ZORTRAX PROTOTYPES FOR ROBOTICS

Manufacturers focus on solutions that shrink the cost and risk associated with production process. With Zortrax M200® they can test before the production has started. With functional prototypes, engineers can correct errors and make improvements in early design stage.

For tough and durable elements, 3D printing with Z-ABS®, Z-ULTRAT® and LPD technology is perfect.

For realistic prototypes with look of finished product, elements that can take abuse, use M200 and its dedicated environment of software and filaments.

KUKA Arm

Robots are 3D printed on Zortrax M200® out of Z-ULTRAT® and Z-ABS® filaments with layer thickness of 0,14mm and 2.87 (1300g) filament usage. Printing time for this prototype is 161h 57min.

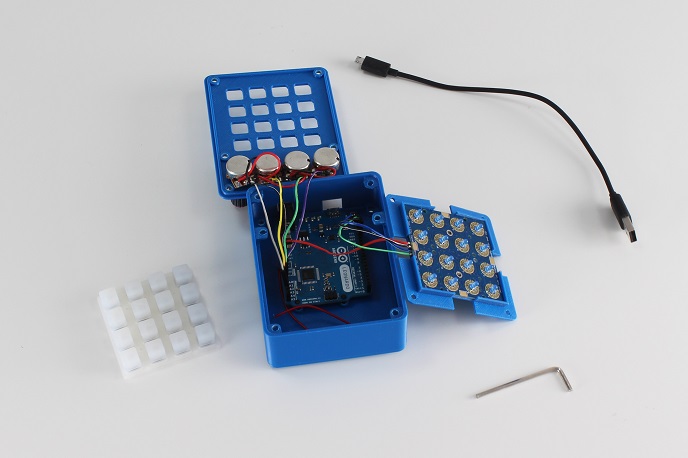

ZORTRAX PROTOTYPES FOR DESIGN

MIDI controller is an example of fully functional 3D printed object. With possibilities of 3D printing industry, designers can bring their creative ideas to reality. Convey ideas to clients and colleagues in a form of a complete model.

Zortrax MIDI

MIDI is 3D printed on Zortrax M200® out of Z-ULTRAT® and Z-ABS® filaments with layer thickness of 0,14mm and 0.23lbs (106g) filament usage. Printing time for this prototype is 13h 1min.

ZORTRAX PROTOTYPES FOR EDUCATION

3D printing fuels students’ creativity, since they can watch and hold their ideas in a tangible form. Prototyping in the classroom is another step in their education. It is not always possible to explain ideas by using words. Using Zortrax M200® 3D printer in the laboratory completes theoretical knowledge on the basis of a particular example.

Zortrax Skull

Human skull is 3D printed on Zortrax M200® from Z-ULTRAT® filament with layer thickness of 0,19mm and 1.02lbs (464g) filament usage. Printing time for this prototype is 44h 21min.