And extreme, rapidly changing temperatures are just one of the problems. Radiation, atomic oxygen bombardment and heavy vibrations components are exposed to during launch are all to be taken into account when choosing materials for space applications. Z-PEEK is a filament made to withstand it all with healthy margins and more. Below, its properties are discussed in more detail.

RADIATION-RESISTANT RINGS Radiation-resistant bearing ring for a spacecraft gimbal 3D printed with Z-PEEK on the Zortrax Endureal

Space Readiness of Z-PEEK

Samples made with the same PEEK blend we use to make Z-PEEK filament have already been launched into space and thoroughly tested. JAXA, the Japanese Space Agency, sent PEEK samples to the International Space Station as part of the MPAC & SEED experiment. Up there on orbit, they have been exposed to space environment without any shielding for as long as 46 months. What’s more, the samples have been placed in holders exerting various level of stress to check if space conditions have any effect on PEEK mechanical performance.

Upon examination back on Earth, PEEK did not exhibit any significant signs of degradation apart from a slight discoloring and increased brittleness. Decreased elastic modulus of the material has been attributed to high levels of UV exposure, which, of all the constituent parts of cosmic radiation, is the easiest to deal with. Atomic oxygen bombardment, charged particles and everything else have been found to have no effect on PEEK. For this reason, PEEK have already been used in various space missions.

The only remaining question was whether 3D printing process in any way affected the properties of the material. To check that, Zortrax have been working with the European Space Agency for over a year. Models 3D printed on the Zortrax Endureal have been sent to ESA’s ESTEC facilities in Netherlands where they underwent demanding tests in thermal vacuum chambers. Parts 3D printed with Z-PEEK on the Endureal passed those tests with flying colors. CT scans of the samples made before and after the experiments revealed that thermal vacuum cycling did not degrade the models in any way.

Ground-Based Applications of Z-PEEK

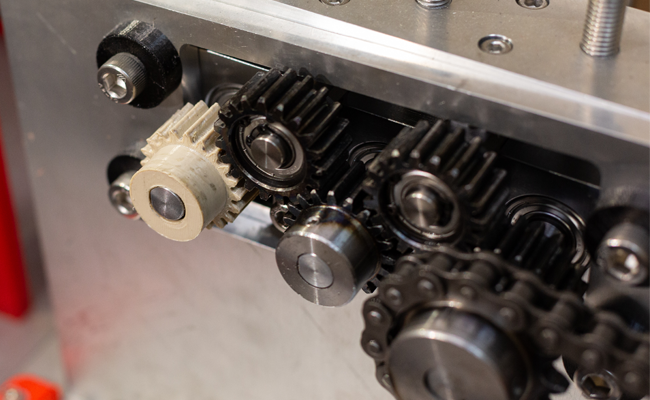

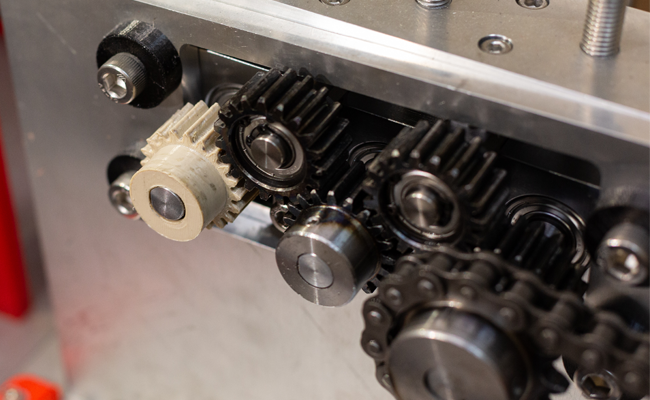

Space applications are not the only ones where using Z-PEEK makes sense. Due to its superior mechanical properties, this filament can work in demanding engineering applications here on Earth as well. The strength-to-weight ratio of Z-PEEK is comparable to stainless steel. Various experiments confirmed, that this material is strong enough to work in polymer-metal gear pairs operating at 1600 rpm under significant loads. Such gear pairs have been working properly for over 22 million cycles.

HEAVY-DUTY GEARS: Z-PEEK is strong enough for gears operating at high speeds under significant loads.

Other research confirmed that in polymer-metal sliding systems, Z-PEEK offers very little debris accumulation which significantly extends the lifespan of mechanisms using such solutions. Z-PEEK is also exceptionally resistant to chemicals which means it can be used with all sorts of greases ensuring proper lubrication in mechanical devices.

Finally, Z-PEEK is capable of withstanding significant pressures and has particularly low permeability. For this reason, it often used in chemical or oil industry as a material for pumps, seals, or gaskets.

3D PRINTED PEEK GASKETS: Seals for piping in oil industry 3D printed with Z-PEEK on the Zortrax Endureal 3D Printer.

Printing Z-PEEK in Dual Extrusion

Z-PEEK is a challenging material to print with. It is extremely tough, so using it to print support structures leads to issues with peeling them off the model. For this reason, Zortrax calibrated the Endureal to print Z-PEEK in dual-extrusion together with easily removable support material.

In this mode, Z-PEEK is printed in very high temperature possible to achieve in Zortrax Endureal’s extrusion system. The support material designed to work in such high temperatures is called Z-SUPPORT High-Temp, and can be used to make breakaway support structures. Supports made with Z-SUPPORT HT are very hard in high temperature but become pliable when the model cools down which makes them easier to remove.

In this workflow, it is possible to print supports that can be peeled out of hardly accessible places. Once the printing is done, the model can also be automatically annealed in the Endureal’s printing chamber to relieve internal stresses and ensure that the material retains its excellent mechanical properties.

PRESSURE-RESISTANT PUMP: Breakaway support structures enable printing partially trapped volumes with Z-PEEK.

Z-PEEK can be ordered through Zortrax Online Store or at Zortrax Resellers, depending on your location.