Z-GLASS vs Z-PETG – Zortrax Printing Materials Comparison

We’ve received many questions since we introduced our latest material Z-PETG dedicated for Zortrax M200 3D printer. Indeed the material share some properties with our well-known Z-GLASS material, however their appliances might be quite different. All in all, for the sake of the best utility of our products we decided to clear things out and provide you with broad description of these two.

The main link between the materials is that they are based on the same substance called PETG. This material, also known under the name of PETG-G is a kind of copolymer which is the result of replacing ethylene glycol with cyclohexane dimethanol in one of the backbones of the substance commonly known as PET. In practice, this means that the modified substance changes its properties and its melting temperature. That simply makes the substance perfect for manufacturing processes like injection molding, thermoforming and additive manufacturing.

The substance is broadly used in producing various kinds of containers, like boxes, bags, bottles and casings. Thats mainly because of its low hygroscopicity – the material doesn’t absorb water from the surrounding, so it can protect the contents from getting wet and doesn’t require special conditions for storage. Yet another feature that makes Z-PETG perfect for storing goods is its high chemical resistance to salts, alkalis and acids. All these properties determined the second common use of Z-PETG in automotive field, as this solid, strong and resistant to substances like oil, grease and others used to lubricate machine pieces, material is perfect for producing working parts of cars and other machines.

Turning back to Z-GLASS. Its in fact a mixture of PETG and 10% of glass fibres that give the material extra resistance and durability and at the same time making it more brittle by lowering its elasticity. However, the feature that distinguishes Z-GLASS from other printing elements is its transparence. The material was initially manufactured to imitate the substances that are made of glass, as the structure of it allows the light to pass throug its surface. Anyone who is interested in producing prototypes of objects which would be finally produced of glass or would have inserted e.g. led lights below its surface, should definitelly consider using this material. The best inspirations and examples of Z-GLASS utilty could be easily found on our blog in posts about ligtbulb and mapping wall.

As it was mentioned in the previous paragraph, the materials based on PETG could be used in various difficult conditions. Although, there are things that should be taken into consideration while deciding about the use of materials:

– Z-GLASS is 50% more resistant to stretching and 100% more resistanto bending

– Z- PETG appears to be 35% more resistant to impact and has 180% better ability to stretch out

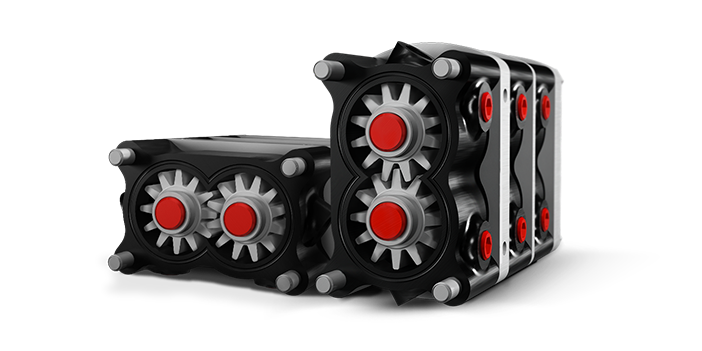

Both Z-GLASS and Z-PETG are dedicated Zortrax printing materials that together with Z-Suite Software and M200 3D printer make a complete Zortrax Ecosystem which guarantees quality an satisfying 3D printing results.