Why You Should Buy the Dual Extruder 3D Printer Zortrax M300 Dual

Summary

- With the possibilities Zortrax M300 Dual offers when printing in the dual-extrusion mode or with demanding filaments, it stands out in the category of dual extruder 3D printers,

- Thanks to the solutions implemented in the printer's design, it can be the perfect tool in engineering, automotive, medicine, and many other fields,

- This is a rundown of the printer's most important features and applied technological solutions.

Dual extruder 3D printers have enriched the market with manufacturing possibilities unknown before. Fancy designs and complex geometries are now within your reach, taking 3D printing projects to the next level. Today, let’s get to know the most important features of a Zortrax M300 Dual – a device that makes it all possible. These are the reasons why the M300 Dual is one of the best dual extruder 3D printers in its category.

Single- vs. Dual-Extrusion

Zortrax M300 Dual’s design has significant advantages over its single-extrusion counterparts. The printer works in the Layer Plastic Deposition Plus (LPD Plus) technology, which means it builds three-dimensional objects with two separate filaments. It’s possible thanks to the two independent hotends, each equipped with a nozzle, which the printer uses interchangeably during 3D printing. Single-extrusion printers, on the other hand, have only one hotend and one nozzle, and so they can use a single filament type for the print job.

That’s why, the M300 Dual can successfully print out 3D models with holes, hollows, crevices, moving mechanisms, or protruding elements. Since the printing process can take place with both the model filament and water-soluble support filament, the post-processing procedures simply boil down to washing models out in water to dissolve supports. After that, 3D prints are ready for evaluation, tests, or everyday use.

Additionally, the printer has an impressive build volume, measuring 265 x 265 x 300 mm (10.4 x 10.4 x 11.8 in), which is enough for both sizable 3D projects as well as short series model production.

Take a look at Zortrax M300 Dual in action! This is a time-lapse video of 3D printing and assembling processes of a remote controller enclosure made with Z-ESD.

Technologically Advanced

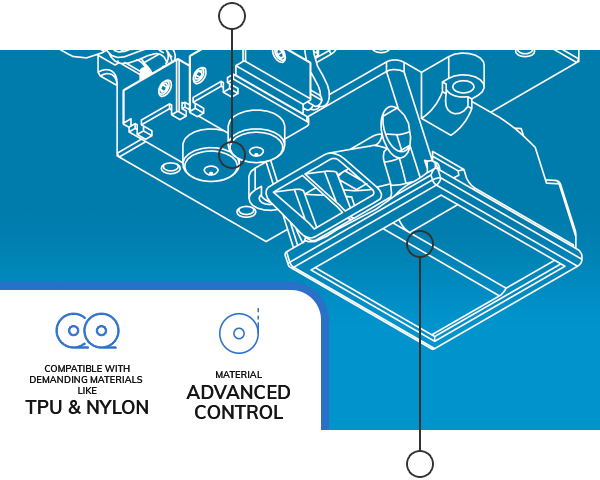

Apart from the double hotend, the M300 Dual offers compatibility with multiple demanding filaments, such as flexible TPU, highly-resistant NYLON, or different types of support filaments. Therefore, the printer can become a suitable tool for projects in engineering, automotive, education, medicine, and many other fields.

Another important feature of the M300 Dual is an advanced material control system implemented in the extruder’s design. Thanks to the sensors which control the 3D printing process from start to finish, the risk of having a failed print is minimized. In the case where the filament is jammed, runs out, or simply gets clogged in the nozzle, the printer pauses and waits to resume the print job until the problem has been resolved. And this safety solution also applies to power outages. Users can rest assured that the printer is going to do its job with almost no supervision. What’s more, the M300 Dual uses 3 fans to cool down the extruder block and 3D prints, all working to boost the efficiency of 3D printing.

On top of that, the M300 Dual proves to be a versatile tool. It supports two types of build plates from the Zortrax offer – the standard perforated plate as well as the glass one recommended for printing raft-free projects. Whichever type of plate is installed in the device, platform calibration is still simple. For that purpose, the M300 Dual uses a capacitive sensor, thanks to which the platform’s proper position is set without the need of keeping physical contact between the nozzle and the build plate.

Easy to Run

The M300 Dual runs on the proven and stable Android system which is accessed through the 800×480 px touchscreen. Navigating through the options available in the printer’s menu is an intuitive and transparent process, which improves the overall user-friendliness of the device.

With just a touch on the screen, users are able to initiate printing, change settings, or open the tools necessary for the printer’s maintenance.

For even better user’s convenience, the M300 Dual comes with Wi-Fi and Ethernet connectivity. After establishing the connection with the local network, transferring files for 3D printing from a computer is a hassle-free and efficient process. All files are stored on the USB drive plugged into the port at the front of the device.

Wi-Fi/Ethernet connectivity brings even more benefits in terms of monitoring the progress of 3D printing. Users can keep an eye on their prints with a live stream from the camera installed in the M300 Dual’s frame. The stream can be previewed in Z-SUITE at any point of the printing process.

Last but not least, managing 3D projects created with the M300 Dual can be even easier with the cloud-based platform – Zortrax inCloud. The M300 Dual is fully compatible with the options available in the service, which allow users to start, pause, and stop the printing process, organize all of the files, check their printers’ history, or receive notifications on their 3D printing equipment. Zortrax inCloud is extremely intuitive and helps to manage and optimize the overall workflow during 3D projects.

More information, photos, and videos of the M300 Dual are available on this Product Page.